MEMBERSHIP MILESTONES:

The Awards Gala at CFACON24 began with a tribute to the milestone anniversaries across the membership. One of the exciting moments in this segment was the identification of historic membership growth, with many new members as well as a robust list of members completing their first-year anniversary.

NEW CONTRACTOR MEMBERS IN 2024

Cotton’s Concrete Construction – Athens, Pennsylvania

East Coast Foundation (Returning) – Center Harbor, New Hampshire

Ely Concrete Inc. – Battle Ground, Indiana

Horseshoe Foundations – Dayton, Wyoming

Jeff Dumas Concrete Construction – West Jordan, Utah

McClure Concrete – Aurora, Colorado

McGee Brothers – Monroe, North Carolina

Moore Masonry LLC – Mount Pleasant, Pennsylvania

NC Pro Substrate Solutions – Pineville, North Carolina

Otter Valley Concrete – Norwich, Ontario

Peachey’s Poured Walls Inc. (Returning) – Mill Creek, Pennsylvania

Precision Concrete Builders Inc. – Broadway, Virginia

Pryker Group Next Generation Concrete – Omaha, Nebraska

R B Narramore Construction – Mount Pleasant, Texas

Rockhard Concrete Construction LLC – Laramie, Wyoming

Rusin Concrete Construction – Colorado Springs, Colorado

Stonewall Concrete Inc. – Manassas, Virginia

Wisconsin Home Improvement – Menomonee Falls, Wisconsin

Yoder Concrete LLC – Goshen, Indiana

NEW SUPPLIERS/ASSOCIATES IN 2024

Big League Construction Supply – Orlando, Florida

Giatec Scientific – Nepean, Ontario

GluDown Inc. – Richardson, Texas

JDR Enterprises Inc. – Alpharetta, Georgia

Mateenbar Composite Reinforcements LLC – Concord, North Carolina

MST Bar – USA – Cincinnati, Ohio

OCM Inc. – Grayslake, Illinois

Rmax, A Business Unit of the Sika Corporation – Dallas, Texas

Transit and Level Clinic – Cary, North Carolina

WP Supply – Indian Trail, North Carolina

NEW CONSULTANTS IN 2024

Double Rainbow Concrete Contractors – Frederick, Colorado

OnePoint Business & Insurance Services – San Jose, California

Pro-Accel – Thornwood, New York

Tier 3 Technology – Ankeny, Iowa

NEW PROFESSIONALS IN 2024

Wafflemat – Grapevine, Texas

1ST-YEAR ANNIVERSARY MEMBERS

All American Concrete Form Inc. – Slatington, Pennsylvania

Fox Construction Systems LLC – Windsor, Colorado

Glass Block Supply – Medina, Ohio

J. Mongillo Concrete Construction – Southington, Connecticut

Mass Concrete Construction LLC – Weymouth, Massachusetts

Mint Drone Shots LLC – Old Saybrook, Connecticut

New York Poly Steel – Newfoundland, Pennsylvania

On Point Concrete Foundations LLC – Gaffstown, New Hampshire

Parmentier Concrete – Pleasant Prairie, Wisconsin

Pinnacle Concrete of the Carolinas LLC – Travelers Rest, South Carolina

Sharma General Eng Contractors – Moorpark, California

In addition, significant membership milestones in five-year increments were recognized. Let’s look at this impressive list.

5-YEAR ANNIVERSARY MEMBERS

Alliance Concrete Pumps – Linwood, Pennsylvania

BIC Auctions – Mount Pleasant, Iowa

Chapin Concrete Contractors Inc. – Chapin, South Carolina

Egress Solutions – Mullica Hill, New Jersey

Five Star Concrete Contracting – Elgin, Illinois

Hardeneye Concrete Inc. – Rapid City, South Dakota

Klosterman Concrete Construction Inc. – Maria Stein, Ohio

Lacko Poured Walls Inc – Columbus, Ohio

M.L. Crose Foundations Inc. – Sibley, Missouri

MBI Construction Inc. – Effingham, Illinois

Menke Poured Walls LLC – Middleton, Ohio

Mills Foundations LLC – Nixa, Missouri

Progressive Foam Technologies – Beach City, Ohio

Ragone Foundation Inc. – Troy, New York

Rocky Geans – South Bend, Indiana

SPS Foundations – Germantown, Ohio

Structural Sales LLC – Lagrange, Ohio

Superior Foundations Ltd. – Dartmouth, Nova Scotia

The Cracksmith – Webster Groves, Missouri

10-YEAR ANNIVERSARY MEMBERS

American Concrete Foundations & Walls LLC – Irondale, Alabama

Helix Steel – Ann Arbor, Michigan

J. T. Hoover Concrete Inc. – Bear, Delaware

Kelly Concrete Company Inc. – Marion, Iowa

Keystone Country Concrete Foundations Inc. – Brookville, Pennsylvania

O’Risky Excavating – Evansville, Indiana

Roffers Concrete Construction – Reedsville, Wisconsin

SLS Financial Services – Kansas City, Missouri

Sterne Construction Group LLC – West Chicago, Illinois

Van Haren Construction Inc. – Faribault, Minnesota

20-YEAR ANNIVERSARY MEMBER

GMX Inc. – Monroe, North Carolina

25-YEAR ANNIVERSARY MEMBERS

Bassett Masonry Inc. – Elmora, Pennsylvania

Boman Kemp – Ogden, Utah

Tru-Form Foundations Inc. – New Ipswich, New Hampshire

Wallmasters Inc. – Middletown, Ohio

30-YEAR ANNIVERSARY MEMBERS

Concrete Wall Company – Helena, Montana

Doggett Concrete Construction – Charlotte, North Carolina

40-YEAR ANNIVERSARY MEMBERs

Modern Foundations – Woodbine, Maryland

Weber Concrete Construction – Zionsville, Indiana

2024 PROJECTS OF THE YEAR The Top-Placing Winners

The 25th annual competition for the Concrete Foundations Association welcomed members to submit projects throughout the first four months of this calendar year to vie for recognition among the storied projects of all time. As the entries were received, surveying the collection can best be described by a single word: diversity. Across the record-tying thirty-three entries, a new record of total categories was set at eleven, leading to the highest total of recognized projects in the history of this competition.

While the projects themselves comprise the most impressive part of this program, the statistics are impressive and attest to the extent of industry leadership in an Association achieving incredible milestones. Fourteen states were represented with nineteen members making submittals—both records. The largest project encompassed over 700,000 square feet of building area and the smallest project just 415 square feet. One project consumed nearly 6,000 cubic yards of concrete and another 244,000 pounds of steel reinforcement. In all, 26,700 cubic yards of concrete and 1.54 million pounds of steel reinforcement were consumed, along with numerous other key materials, such as twisted micro steel reinforcement, GFRP reinforcement bars, and much more.

Projects of the Year showcases the work of top concrete professionals across the country, demonstrating craftsmanship and creativity that set standards for the cast-in-place concrete industry. “I appreciate that my coworkers love to submit jobs to the CFA Projects of the Year program,” said Kirby Justesen, president of SCW Footings & Foundations, who holds the record for the most CFA project awards (all-time and in a single year). “I think it’s a fun program that builds pride and unity for the company. The general contractor or owner of the project loves it when we hand deliver a winning plaque to them.”

Many CFA members have realized that this program has become a cornerstone of their company’s marketing. Herbert Construction Company in Marietta, Georgia, is one such member; they have submitted projects now for more than a decade. “At Herbert Construction Company, we are committed to hiring exceptional talent to produce outstanding work. Winning a CFA Project of the Year award not only validates our commitment but also fortifies our company culture,” said Dante V. VanSol, marketing manager. “These accolades serve as a powerful testament to the excellence our team strives for daily. They provide our crew with a profound sense of pride and accomplishment, knowing their work is celebrated on a national stage. The sight of our Project of the Year plaques often sparks reflection and inspiration, fueling our collective ambition to achieve even greater successes in the future.”

Annually, the program maintains a legacy while celebrating and honoring the hard work that makes this industry worth the time to tell its story. “I’m sure most contractors tackle challenging and difficult jobs,” Justesen said. “Yet, sometimes you are not quite sure how you are going to do the job or even what the outcome might finally be. But, you keep thinking and doing, one step at a time until finally it’s done. Submitting to Project of the Year is a way to show our team and others that we did a tough one and it’s fun and rewarding.”

_______________________________________________________________

GRAND PROJECT OF THE YEAR: NON-FOUNDATION STRUCTURAL ELEMENT:

CUSTOM CONCRETE COMPANY INC.

THE BRIDGES – WESTFIELD, INDIANA

This structural concrete project represents a significant departure from traditional foundations, highlighting the contractor’s dedication to innovative construction practices and meticulous technical execution. Central to the project are nineteen uniform architectural archways, each spanning 20 feet with a 1-foot inset, adorned with 1-foot-2-inch decorative corbels. These elements add elegance, especially in areas with curved walls and complex corners, making the structure a standout achievement in architectural design.

During the preconstruction phase, the contractor implemented value engineering alternatives, conducted wall mockups for client assessment, and ensured continuous communication with the client. Collaboration with the safety team was integral to maintaining rigorous safety protocols throughout the project. Additionally, the contractor partnered with skilled subcontractors to enhance craftsmanship through detailed CAD drawings, layout planning, and precise rebar fabrication.

The complexity of the project was primarily driven by the intricate arches, which required the development of precise building templates to ensure consistent rebar cage sizing. Key structural details included a continuous longitudinal footing key, measuring 2 feet 2 inches tall by 1 foot thick, extending 680 linear feet. This foundation design was critical for stability, particularly in load-sensitive areas such as steps.

Covering approximately 680 square feet and 660 linear feet, the structure utilized 1,500 cubic yards of concrete—800 in the footings and 700 in the walls—along with 214,000 pounds of steel reinforcement. The walls were built 13 feet high and 2 feet thick, reflecting the project’s robust engineering and design.

The project also involved the use of specialized materials and processes. A temporary road was constructed to facilitate access for material handlers, concrete trucks, and crew personnel. Scissor lifts served as essential work platforms, requiring comprehensive fall protection training and systems, especially during rebar installation and arch framing.

The contractor was selected due to their local poured-wall expertise, extensive experience in the cast-in-place wall industry, and commitment to continuous client communication, and their approach was pivotal to the project’s success. This project exemplifies their unwavering commitment to excellence, safety, and innovative construction practices, setting a high standard in the industry.

_______________________________________________________________

EXISTING STRUCTURE ADDITION

HERBERT CONSTRUCTION COMPANY

PAULDING COUNTY PRIVATE RESIDENCE – MARIETTA, GEORGIA

This project seamlessly integrated an above-grade concrete home addition with an existing structure, optimizing space and functionality within a compact footprint. Spanning 493 square feet with 103 linear feet of walls, it required meticulous planning and execution. A total of 88.5 cubic yards of concrete were strategically placed, with 17.5 in footings, 22.5 in exposed walls, and 48.5 in the basement, elevated slab, and exterior slabs-on-ground.

The homeowners were deeply involved, making daily changes to the project. Both the husband and wife, along with their family members—who had extensive construction experience—provided significant input throughout the planning and construction phases. One of the key challenges was preserving the existing roof over the original screened porch. The team had to carefully brace the roof without interfering with the construction of the walls and basement slab, then re-brace it during the elevated slab construction.

In-house engineering played a critical role, with rebar in the elevated slab designed to span the distance between walls and accommodate cantilevered sections. Additionally, a waterproofing batch admixture called Xypex was used in the elevated slab. This admixture reacts with moisture and by-products of cement hydration, creating a non-soluble crystalline formation that permanently seals the concrete, preventing water penetration.

Herbert Construction Company’s vice president of operations, Amanda Morris, said, “While we can describe our work to prospects, winning a national award makes a far stronger impression. It distinguishes us and leaves a memorable mark that words alone can’t match. This national award demonstrates the exceptional quality and dedication behind our projects.”

Attention to detail was paramount, with intricate features like dual-board-forming techniques, a secure concrete safe room, and integrated conduit for electrical fixtures. Mock-ups were constructed to refine board forming and window block-out designs, ensuring impeccable execution. This project exemplifies the fusion of architectural innovation and structural ingenuity, elevating both form and function within limited space.

_______________________________________________________________

SINGLE-FAMILY FOUNDATION – 10,000 TO 15,000 SQ. FT.

SCW FOOTINGS & FOUNDATIONS INC.

WOODLEY RESIDENCE – SALT LAKE CITY, UTAH

This project showcases an exemplary effort for the construction of a complex, single-family residence, featuring an extensive concrete foundation covering 10,804 square feet with 142 linear feet of concrete structure. The project utilized a total of 574 cubic yards of concrete, distributed as 259 cubic yards in the footings and 315 cubic yards in the foundation walls. To ensure structural integrity, 42,877 pounds of steel reinforcement were incorporated, with 18,543 pounds in the footings and 24,334 pounds in the walls.

The foundation construction required a variety of continuous footings, including widths of 24 and 36 inches by 12 inches thick; 24 inches by 18 inches thick; and 66, 87, and 102 inches by 14 inches thick. These footings navigated twenty-three steps, accommodating 83 feet of vertical grade change. The isolated footings added another layer of complexity, featuring 12-inch-thick pads in dimensions of 24, 36, 48, 54, and 60 inches square, a 14-inch-thick pad of 66 inches square, a 16-inch-thick pad of 84 inches square, and a 20-inch-thick pad of 96 inches square.

The wall construction mirrored this complexity with fourteen different heights ranging from 3 to 16 feet and thicknesses of 8 and 10 inches. These walls included sixty-seven steps, managing 127 feet of vertical grade change. The intricate wall geometry necessitated three window openings and 110 corners, making precise layout crucial. An automated layout system was invaluable for achieving the required precision.

This project exemplifies the hard work and dedication of the entire team, resulting in a foundation completed with precise craftsmanship, demonstrating an outstanding achievement in complex residential construction.

Kirby Justesen, the company president, said, “This is yet another example of the hard work and dedication required from the entire team to complete an intricate job like this one.”

_______________________________________________________________

SINGLE-FAMILY FOUNDATION – 2,000 TO 5,000 SQ. FT

CHAPIN CONCRETE

ROCKY COVE ROAD HOUSE, POOL AND SITE WALL FOUNDATIONS – CHAPIN, SOUTH CAROLINA

This category-winning entry features a foundation of 900 linear feet for a house with a 4,900-square-foot footprint. The scope included the house, site wall, and pool foundations, utilizing 560 cubic yards of concrete—235 in the footings and 325 in the walls—and 42,000 pounds of steel, over half of which was used in the footings.

The footings were substantial, ranging from 3 feet wide by 12 inches thick to larger spread footings covering 2,300 square feet. Retaining wall footings measured 8 feet wide by 12 inches thick with one-foot elevation increments totaling approximately 10 feet. Wall heights varied from 2 feet to 9 feet, with thicknesses of 8 and 16 inches, incorporating 1,584 linear feet of brick and truss ledges.

The project was completed in two stages: house foundations first, followed by the pool and site walls due to design delays. Heavily engineered footings supported the weight of natural stone and a slate roof. Critical elevations ensured seamless transitions between the house, site walls, and pool.

Technical challenges included installing brick and truss ledges at varying elevations using Western Forms® brick ledge bars for a clean finish. The interior area featured piers 14–16 –inches in diameter for framing beams. A total station facilitated precise layout without batter boards, maintaining accurate elevations throughout. This meticulous approach ensured cohesive interfacing of the house, site walls, and pool.

When asked about the significance of this project, Chris Marra, president of Chapin Concrete said: “We feel that this project showcases our ability to handle projects with complex details and a discerning clientele. Our crews continue to demonstrate their ability to work through projects requiring tremendous attention to detail and provide a high-quality experience and finished product for our clients.”

_______________________________________________________________

SINGLE-FAMILY FOUNDATION – 5,000 TO 10,000 SQ. FT.

SCW FOOTINGS & FOUNDATIONS INC.

SCHOENVOGEL RESIDENCE – SALT LAKE CITY, UTAH

The residential concrete foundation for this project, while seemingly modest at 5,384 square feet, was a feat of complexity and precision. The foundation required 567 linear feet of concrete, reinforced with 28,237 pounds of steel, over 3,000 in the footings and more than 25,000 pounds in the foundation walls. In total, 326 cubic yards of concrete were placed, with 76 cubic yards in the footings and 250 cubic yards in the walls.

The project demanded significant technical expertise due to the varied and challenging structural requirements. The continuous footings, which were 12 inches thick, ranged in width from 20 to 48 inches, while the spot footings measured between 36 and 54 square inches. To accommodate a 77-foot vertical grade change, the footings required 18 steps. The foundation walls themselves varied greatly, with 10 different heights ranging from 3 feet to a towering 22 feet. The wall thicknesses also varied, from 8 inches to 24 inches, with the thickest walls supporting the tallest sections at 14 and 22 feet. Additionally, the garage walls featured a 4-by-18-inch-deep shelf designed to support a suspended concrete slab.

One of the most formidable challenges of the project was constructing a 22-foot-tall, 24-inch-thick wall. Given its size, the potential for blowouts was a significant concern. To mitigate this risk, the team took extraordinary precautions, meticulously triple-checking the form ties and bracing systems before each pour. The wall was poured in three lifts to ensure it remained straight and plumb, with each step carefully executed to prevent structural failures. This attention to detail and problem-solving exemplified the complexity of the project and the high level of expertise required to complete it successfully.

_______________________________________________________________

ABOVE-GRADE CONCRETE HOME:

PLATINUM CONCRETE HOMES

CARKHUFF RESIDENCE

This impressive two-story concrete home, built as a private residence, boasts three bedrooms and three bathrooms within its 2,600 square feet, complemented by a 600-square-foot garage and patio. The construction utilized a substantial 269 cubic yards of concrete, with the walls alone accounting for 249 cubic yards. Reinforced with a blend of steel and glass-fiber bars, the structure was achieved through a monolithic wall and deck pour, ensuring unparalleled strength and durability. The 9-foot11-inch-high walls are engineered to deliver exceptional insulation, achieving an R-55 rating through 12-inch-thick sandwich walls, which incorporate an innovative plastic barbed clip system for precise insulation-board positioning.

The foundation footings, all 12 inches in depth, feature three elevation steps, enhancing stability and integration with the surrounding landscape. Additionally, cast-in-place horizontal beams were meticulously constructed to support the deck, further reinforcing the home’s robust structure. To optimize construction efficiency, a single set of forms was cycled six times, significantly reducing the amount of equipment required and showcasing the practical ingenuity of this build.

This home stands as a testament to the efficiency and durability of concrete in residential construction, offering a sustainable, resilient alternative to traditional building materials. Its innovative design and execution not only ensure lasting performance but also highlight the potential for concrete to revolutionize modern housing solutions.

_______________________________________________________________

SINGLE-FAMILY FOUNDATION – UNDER 2,000 SQ. FT.

SCW FOOTINGS & FOUNDATIONS INC.

DANA POOL HOUSE – SALT LAKE CITY, UTAH

Enclosing 880 square feet with 225 linear feet of concrete structure, the project required 141 cubic yards of concrete and nearly 16,000 pounds of steel reinforcement, showcasing meticulous engineering and design precision.

The footings were particularly noteworthy. With 12-inch-thick continuous footings of varying widths (20, 36, 84, and 90 inches), the design incorporated two footing steps to accommodate 5 feet of vertical grade changes. Additionally, spot footings varied in thickness, with 12-inch-thick footings ranging from 30 to 42 square inches, and a 10-inch-thick footing spanning 19 feet9 inches by 9 feet-1 inch. These footings consumed 71 cubic yards of concrete and nearly 4,000 pounds of steel.

The walls added another layer of complexity. Despite the small footprint, the walls varied in height, featuring nine unique dimensions from 2 feet 6 inches to 18 feet 8 inches. These walls, ranging from 6 to 10 inches thick, matched the footings’ concrete volume at 70 cubic yards and required nearly 12,000 pounds of steel reinforcement.

Architectural aesthetics were also a priority. The walls featured a smooth ply finish with faux cones and ¾-inch chamfer, applied double-sided. Six of the eleven top-of-wall sections included slopes of 15 inches through 5 feet, and the design incorporated six window openings and one door opening.

This foundation project demonstrates how thoughtful design and engineering can achieve remarkable results on a modest scale. Despite its size, the project demanded high levels of detail and precision, making it a deserving category winner.

_______________________________________________________________

NON-BUILDING FOUNDATION

CUSTOM CONCRETE COMPANY INC.

THE SPILLWAY – WESTFIELD, INDIANA

Commitment to excellence and innovation is epitomized in this category-winning concrete construction project, which delivered a new spillway on a dam, covering 11,066 square feet and featuring a 140-foot-long concrete wall. The project utilized 370 cubic yards of concrete—290 in footings and 80 in walls—and incorporated 40,000 pounds of steel reinforcement, strategically distributed for maximum structural integrity.

The spillway’s design presented significant challenges, including the installation of footings on a 30-degree slope along the dam’s embankment. The mat foundation slab, laid at a matching slope and a 59-yard grade, was engineered to ensure efficient water runoff. The wall’s innovative design featured both vertical and horizontal slope considerations, including a 12-degree, 22% gradient at the base to align seamlessly with the adjacent channel. This careful planning and precision engineering ensured that the spillway integrated harmoniously with the surrounding terrain and water features.

The steep hillside location, complicated by the presence of a lake atop the dam, required draining over five million gallons of water to safely complete the final phase. This operation demanded meticulous planning to maintain safe access for both equipment and personnel, turning the terrain’s natural challenges into a showcase of the team’s expertise.

Advanced laser scanning technology further enhanced the project’s success; it was used for the off-site pre-casting of splash blocks, ensuring precise as-built measurements and optimal water flow down the spillway. The project integrated an innovative use of a special white wax sealer and strictly adhered to Environmental Protection Agency water regulations to underscore a commitment to environmental stewardship.

“Handling over 800 tons of stone with unparalleled precision coupled with the precision of on- and off-site concrete construction, we not only met but exceeded expectations,” said Jason Ells, CEO for Custom Concrete. “This project stands as a testament to our ability to transform challenges into opportunities, delivering outstanding results for our valued clients.”

_______________________________________________________________

SINGLE-FAMILY FOUNDATION – OVER 15,000 SQ. FT.

GRIFFIN MASONRY

MOLLYPOP – CHARLOTTE, NORTH CAROLINA

This monster project showcases exceptional construction across its expansive 15,590-square-foot footprint and 1,531 linear feet of precisely crafted concrete walls. The project required 1,086 cubic yards of concrete and 70,000 pounds of steel reinforcement, along with an additional 271 cubic yards for flatwork and slabs-on-ground, ensuring outstanding structural integrity. The complex foundation, featuring footings from 24 to 156 inches reinforced by 20×16 shear keys, utilized 380 cubic yards of concrete and 32,400 pounds of steel. Foundation walls, ranging from 1 to 18 feet in height, incorporated 445 cubic yards of concrete and 37,700 pounds of steel across various rebar configurations.

The project’s success was anchored in a meticulously planned, four-phase approach, developed in collaboration with the builder, designed to address the challenges posed by the immense size, intricate terrain, and proximity to neighboring properties. “The building business is very challenging, and we’re fortunate to work with fantastic trade partners like Griffin Masonry and their affiliate companies,” said Jonathan Chiott, president for Chiott Custom Homes. “When building complicated luxury homes, it’s extremely important to have a team like Griffin to handle everything from the footings to poured concrete walls, block and brick masonry foundations and veneers, and concrete flat work. It makes the job much less stressful to know Griffin handles everything turnkey and they always stand behind their work.” When asked about the impact of working with this client, Rob Merrell, director of sales for Griffin Masonry, said, “Our 15-year relationship with Chiott Custom homes is a testament to what can be achieved through a true partnership between builder and trade.”

In Phase 1 critical benchmark elevations were established, such as the lake, pool wall, basement slab, and garage slab. These were crucial for ensuring that all subsequent construction steps aligned perfectly with the design plans. Phase 2 consisted of comparing the benchmarks with planned elevations to ensure accuracy. This validation process involved assessing the plan accuracy and adjusting estimates, allowing Griffin to prevent potential discrepancies before construction commenced. In Phase 3 implementation began with setting the backyard and pool deck elevations, followed by pouring footings and walls, which ranged from 3 to 18 feet in width and height, respectively. The basement foundation included excavation, pile driving, and pouring the slab with waffle ribs. The garage foundation involved constructing footings, walls, and the garage slab. Finally, Phase 4 focused on tackling the 240-foot distance from the street to the lakeside wall and the 71-foot elevation change. An innovative two-pump system for efficient concrete transfer and custom transportation plans for steep terrain was incorporated. Throughout the project, strong communication with neighbors was maintained, mitigating disruptions through noise control, debris management, and effective traffic measures.

Despite the complex challenges, Griffin’s technical precision, phased execution, and collaboration ensured a high-quality outcome that met and exceeded expectations. “This project showcases the incredible team we have assembled at Griffin Masonry, from our estimators and field supervisors to our foreman,” Merrell said. “This award is shared across every division at Griffin Masonry, including timber piles and masonry. It also underscores the strength of our collaborative approach within the Trowel Craft Group family of companies; Blue Dot Readi-Mix, BluRebar, and Patriot Pumping each played an active role in this project’s success.”

_______________________________________________________________

COMMERCIAL/AGRICULTURAL FOUNDATION

SOUTHERN NEW HAMPSHIRE POURED WALLS

PORTSMOUTH MIX USE – LONDONDERRY, NEW HAMPSHIRE

This unique commercial concrete foundation project involved an addition to a building from the 1800s, presenting several challenges and requiring innovative solutions. The addition, featuring an 18-spot parking garage a full level below street level, had a 15-degree skew from the original building to fit the lot constraints. The project covered 23,000 square feet and utilized 790 cubic yards of concrete—380 in the footings and 410 in the foundation walls—along with 50,000 pounds of steel reinforcement.

The complex footings included 300 linear feet of 12-foot-wide by 2-foot-thick sections, 150 linear feet of 6-foot-wide by 18-inch-thick sections, and 144 linear feet of 3-foot-wide by 12-inches-thick sections, alongside two elevator pit slabs. Additionally, the footings stepped six times in 2-foot jumps. The foundation walls required 150 linear feet of one-sided forming, standing 17 feet high by 18 inches thick, constructed using the contractor’s unique Doka® A-frame system. The remaining walls were traditionally formed, ranging from 16 feet high by 16 inches thick to 10 feet high by 16 inches thick, and included two radius entry walls into the parking garage.

The project also required 145 cubic yards of shotcrete to fill voids against the existing building’s stone foundation. Detailed wall features included 14 beam pockets, 37 weld plates for structural steel, and various depths for brick and slab shelves. Despite space constraints and the complexities of working downtown, the project was completed smoothly and on time, using three different forming systems and only two mobilizations over three months.

_______________________________________________________________

MULTI-FAMILY/TOWNHOME/APARTMENT FOUNDATION

HERBERT CONSTRUCTION COMPANY

CHATTANOOGA APARTMENT COMPLEX – MARIETTA, GEORGIA

The concrete foundation project for this expansive apartment complex in Chattanooga, Tennessee, was a formidable endeavor. Covering over 700,000 square feet and extending more than 7,300 linear feet, the project required nearly 1,900 cubic yards of concrete and approximately 112,500 pounds of steel reinforcement. The primary focus was on the construction of trench footings with integrated slabs to meet frost requirements, with footings set two feet below grade for all seven buildings.

The project presented a significant challenge: placing, screeding, and floating the concrete footings positioned two feet below grade. Following the footing construction, CMU blocks were laid atop the trench footings to form the frost walls, which were subsequently grout-filled before the slab-on-grade was placed. Beyond the standard footings and slab work, the construction included two imposing walls, each 10 feet 6 inches tall and 234 feet 8 inches long, along with additional walls that stepped up with the grade.

Precision was paramount, with each building meticulously detailed using in-house CAD. The plans were then translated to the field using a robotic total station, showcasing the team’s expertise. The remote location of the project site necessitated meticulous planning and scheduling for material delivery and formwork, especially during the rainy season, to ensure no delays occurred due to forgotten items.

A strategic pre-construction plan allowed for direct placement of concrete from ready-mix trucks, eliminating the need for a concrete pump. This required constructing each building in two phases to maintain truck access. Despite encountering a blowout while pouring one of the tall walls—caused by an old form—the team swiftly managed the setback. They replaced the forms and completed the pour, resulting in minimal patching and an aesthetically pleasing wall. This successful outcome highlighted the skill and responsiveness of the construction crew, underscoring their proficiency in handling unexpected challenges.

“Winning the CFA Project of the Year award for a project I managed is truly gratifying,” said David Summey, general field superintendent at Herbert Construction. “With over two decades in the industry, I’ve witnessed countless changes, yet the joy of tackling complex challenges and creating enduring structures remains constant. This recognition not only reminds me of the hard work and innovation invested in the project but also reinforces the satisfaction of delivering value that will stand the test of time for our clients.”

For Sale: New Aluminum Forming Panels

CFA supplier member has offered the following set of new aluminum forms for sale. Catch this one quick before it is gone.

For Sale: Used Steel-Ply Forms

A CFA supplier member is offering a complete set of used 24″ x 8′-0″ steel ply. Total count over 500 forms along with fillers and corners.

Gratitude and a Sense of Accomplishmen

Jason Ells Custom Concrete Company Inc. jasone@customconcrete.com

As I pen this farewell letter, it is with a heart full of gratitude and a sense of accomplishment that I reflect on my two years serving as your president. These past two years have been an incredible journey, marked by significant milestones, collaborative efforts, and shared triumphs.

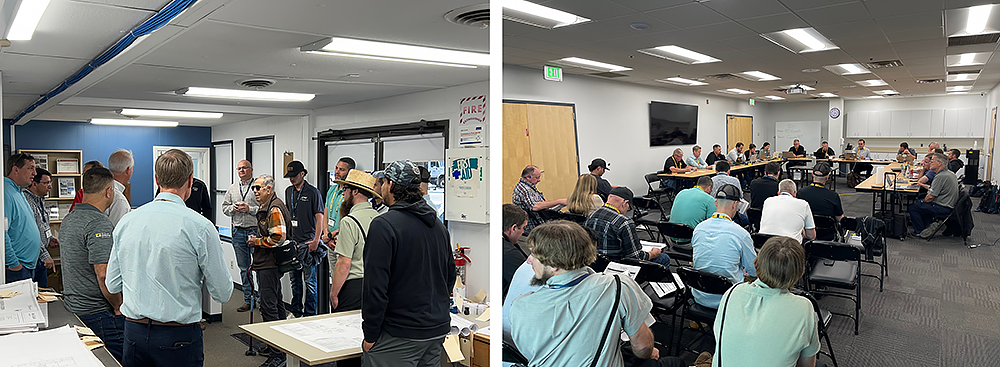

One of the initiatives I am most fond of is reestablishing the executive retreats. These retreats allow us to step away from our day-to-day operations and spend quality time at various members’ places of work. These gatherings foster an environment where we can learn from each other, share best practices, and grow as companies and as a more cohesive Association. The insights and camaraderie we gain at these retreats prove invaluable, reinforcing our commitment to excellence and innovation within our industry.

Another significant accomplishment is conducting our first-ever 360 review at the board level. This comprehensive review allows us to gain a better understanding of our performance, strengths, and areas for improvement. The feedback gathered is instrumental in guiding our strategic focus and ensuring that we are continually aligning our efforts with the needs and expectations of our members. This initiative sets a new standard for accountability and growth within our leadership team.

We also undertook the ambitious project of revamping our website and member management system. This overhaul was aimed at enhancing user experience, improving accessibility, and providing more streamlined and efficient services to our members. The new website is now not only more visually appealing but also more functional, ensuring that our members have easy access to resources, updates, and networking opportunities. The updated member management system has simplified administrative processes, allowing us to focus more on delivering value to our community.

A highlight of my tenure is the launch of our Golden Tie Program. This initiative is designed to recognize companies and individuals who connect potential members to our association through warm introductions, referrals, and recommendations. Our current members are our best source for building our membership base, and this program celebrates their outstanding contributions. Celebrating the first award recipient at last year’s convention was a proud moment, and I look forward to seeing this program continue to honor excellence and inspire future leaders.

None of these accomplishments would have been possible without the unwavering support and dedication of our incredible staff and board members. Their hard work, passion, and commitment have been the driving force behind our successes. I am deeply grateful for the opportunity to have worked alongside such a talented and devoted team. Together, we have laid a strong foundation for continued growth and innovation.

As I step down from my role, I am filled with optimism for the future of our association. It is my great pleasure to welcome Sean Smith of MPW Construction Services as the incoming president. Sean is a second-generation leader of his business and a second-generation president of our board, bringing a wealth of experience, vision, and passion to this role. I have no doubt that under his leadership, our association will continue to thrive and reach new heights.

Thank you once again for the honor of serving as your president. I look forward to supporting Sean and witnessing the continued success of the Concrete Foundations Association.

Warm regards,

Jason Ells

Outgoing President

Concrete Foundations Association

It is Hard to Believe

June is here and with it a rush of activity in most of your businesses and the CFA. June is the last month of our fiscal year. It is the last month of significant work to get CFACON24 right. It is also the first true month of summer and the myriad of conflicts surrounding key conversations that will lead to and produce CFA’s future vision. Perhaps you might rationalize similar challenges occurring in your own businesses. Though the details may be different, what we all likely have in common is the feeling that it’s hard to believe we are here.

Reflecting on the past year I am overwhelmed with gratitude for and pride in our CFA community. This Spring we hosted the latest Executive Retreat. Modern Foundations and Bartley Corp, two of the longest tenured CFA members, played enormous roles in the framework that led to the retreat’s success. You’ll see some of the evidence of their great work on page __ in this issue or you can watch the recap video here: https://bit.ly/3UP3kzq. We entertained the new ACI President, Michael Paul, during our Board meeting at the impressive and new ACI Resource Center in Maryland. Our members experienced the legacy of the U.S. Naval Academy, dined together at the Annapolis Market House, and spent quality time together during bus transportation and shoulder moments in the lounge at The Hotel at Arundel Preserve. These snapshots of relationship building exemplifies the framework CFA has returned to accentuate the personal aspect of its membership. After twenty-three years in this role, it is hard to believe how, time and again, the progress and success we achieve remains new, exciting, and refreshing.

In his last letter as CFA President, Jason Ells shows his appreciation for all that has taken place. He has served for two years of amazing development, energy, and growth in this Association, and he deserves all our appreciation! What an amazing leader he has been, continuing the legacy of the amazing leaders I have worked with in the presidency of this Association. He committed to weekly teleconferences with me, monthly Executive Committee Zoom sessions, and re-establishing the quarterly Board meetings. Perhaps his biggest influence during his presidency, however, is his attention to metrics, both in the 360 evaluation, as well as the practice of setting goals and evaluation criteria. He has lived a leadership mantra of “if your WHY is not big enough your excuse will be.” It is hard to believe that two years are nearly gone since his predecessor, Doug Herbert handed him the reins. He now prepares to do the same to second generation president, Sean Smith.

It is hard to believe…and yet, just look around. This Association is changing lives, changing businesses, changing workforces, and changing the built landscape. As we look ahead to the start of our 50th year, I certainly understand the challenges to “invest in” or “work on” your business, however, if you read this and question whether you are, or know you are not a “CFA member” my challenge to you is to quit holding out. Let us help!

Caught-In-Action

Challenging the industry to always improve, this photo was captured by a CFA member proud of one of their crews. “This photo shows some of our team members forming and shoring an elevated structural concrete slab,” states Doug Herbert, President of Herbert Construction Co. in Atlanta. “The award-winning project was made possible by the great group of guys in the photo (L-R): German Morales (top), Francisco Pena, Jermaine Clayton, and Miguel Perez. Their expertise in tackling tough projects, and their willingness to learn new skills are invaluable.” Doug added, “This project also included a tricky one-sided concrete wall poured against a 100-year-old home. With terrific team members like these guys, our company has become known for excelling at complicated projects like this one.”

Do you have photos of exceptional work or aspects of your business “caught in action” you would like to nominate? Send them directly to CFA Executive Director, James Baty at

jbaty@cfaconcretepros.org.

How Would Your Company Benefit From an Expert Talent Attraction Consultant?

By RecruiterGuy – Bill Humbert

Running a business is not easy. There are so many moving parts, not the least of which is recruiting (Talent Acquisition or Talent Attraction).

Does your business have a line of qualified candidates (Project Managers, Concrete Superintendents, Finish Superintendents, Commercial Drivers, and Laborers) outside your figurative gates desiring to work with you? If your company has that line at your gates, consider yourself fortunate. Your concrete business is one of 1,000 companies that ‘attracts candidates,’ instead of attempting to acquire ‘talented workers.’

How much money do you spend per year on newspaper ads or job boards to identify potential new employees? How much time is spent selecting the best candidates? How long do those employees remain with you before you need to begin the process over again? How much revenue are you spending training new employees to bring them up to your company’s expected performance quality? Has your business’ employee shortage led you to spend extra money for overtime employee compensation (that may not have been included in the estimate) to meet deadlines?

Wouldn’t it be better to turn that spending into profitability?

My experience includes 8 years working with two general contractors in the Washington, D.C./Baltimore area. My last position was as the Superintendent on a garden apartment/townhouse project in Northeast Washington, D.C. I understand the benefits of having talented labor working on your projects, something achievable by first attracting and securing the best, most qualified candidates.

To transform your company’s loss into a win, examine your recruiting practices. Do they follow this process?

Step One –Identify the NEED for a New or Replacement Employee. Most companies are on target with this first step. Generally, the top organizations ask the managers for some documentation to justify adding to the headcount. This justification can be simple (scope creep, weather, other contractors, etc.)!

Step Two – Create a Job Description that truly describes the expectations for employee success during the first year. For hourly workers, it is important to include how they may increase their wages by adding new skills. This also gives the company a way to measure starting wages for experienced labor (for instance, a candidate already has experience finishing concrete vs. someone with no or little experience in concrete labor).

Step Three – Source Potential Candidates. Consider – if your job description does not reflect the expectations for the first year of employment, your business will source the wrong candidates. Sourcing candidates correctly is more important than simply posting positions online and hoping the best candidates are looking at them. Hint—they are currently working, not looking at online postings or newspaper ads. According to metrics by the career transition industry, only 25% of all labor jobs are filled by responses to job postings or ads. One way to attract new employees is to add a small referral bonus for your current employees. Here you tell the current employees you will pay them a bonus of some amount (depending upon the level of concrete skills or position) for anyone they refer to the company and would enjoy working with again. Be sure to create a time requirement – paying an initial amount after the new employee stays with you for a month. The referring employee then receives the balance of the bonus if the new employee remains working with the company for 6 months (or some other amount of time)

Step Four – Candidate Interviews. Has your business trained your managers how to conduct effective interviews? If not, they have not been trained to identify and select the most qualified candidates.

Step Five – Candidate Offer. The candidate’s offer should reflect where the candidate’s skills and experience fit with other members of the manager’s team (Tied to Interview Training).

Step Six – Due Diligence. Due diligence includes drug testing, background investigation, and reference checks. Skip one of these due diligence steps and the company risks making a bad hire.

Step Seven – Offer Negotiation. Once a candidate has been vetted, an organization may negotiate the offer with the selected candidate. There are tools to use in this negotiation and I can help provide them. Remember titles may differ from contractor to contractor. In the labor market, their skills and concrete experience in connection with specific duties they’ll perform in your company determine their worth to you.

Step Eight – Close the Candidate. Remember when you last interviewed for a new job? What convinced you to accept the offer? Discuss with the candidate why your concrete contracting business provides them an opportunity to grow, work with a great team, receive benefits and security, etc.

Step Nine – Start the Selected Candidate. The start date to convert the candidate to an employee should be considered roughly the same length as the delivery of a product or service in the sales process. Each is established by the resources available to produce or prepare and the parameters should be set prior to offering the position, just like they are for offering product or solution.

Step Ten – Onboarding (or Orientation). This is an important opportunity to welcome new employees. Remember first impressions are remembered. Present them with their company hard hat, provide safety training, and discuss your process to grow their skills, as well as their advancement potential, etc.

Step Eleven – Engage Employees. When you engage new employees at the beginning of their employment – and continue to engage with them, you will increase employee satisfaction and encourage employees to engage in return.

Step Twelve – Employee Retention. Why is employee retention important? Considering that a contractor will invest in growing their employees’ skills the talent attraction process is made more efficient and effective when there is less energy necessary attempting to attract and train new laborers when you add more value to your team by retaining them. Retention of your best employees becomes a huge step in attracting new employees as candidates recognize the loyalty and longevity of your business.

Did you think attracting the best employees was “Just Recruiting?”

The Talent Attraction Process Strengthens Your Company

How do you determine the best Talent Attraction Recruiter for your concrete business? It depends on the size of your concrete company. If your company is small, you may recruit new business and new employees yourself. If your concrete business is large and growing, you may benefit from hiring an outside recruiter. Consider asking these three questions during an interview.

Does the prospective recruiter have Human Resource Recruiting or Professional Recruiting experience? Human Resources is an important function within your company. Successful professional recruiters are sales professionals. Consider – A professional recruiter typically is not an employee of a construction company, but their previous employer is a Recruiting firm, possibly with experience recruiting temporary labor for construction. This type of experience develops skills in developing clients as well as recruiting candidates to work with those clients. The duality and specificity of these skills provide the framework for successful recruiting.

Ask the prospective recruiter to walk you through how they would improve your recruiting process. If their response does not list the steps above, or worse, they suggest finding new boards to place job openings, it is time to thank them for their time.

Ask the recruiter, “Tell me when you used your favorite close to gain an offer acceptance from a reluctant candidate. Describe your close.”

Most companies can improve their recruiting. As the Leading organic search engine result for “Talent Attraction Consultant,” I am happy to assist your business in attracting the best workers. My consultancy will benefit your concrete business by helping you hire competent and qualified employees. I am RecruiterGuy and having listened to your stories as a consulting member, I am here to not just help you, I will also donate 40% of my fee to the Concrete Foundations Association. Let’s get to work!

Gearing Up For Success: Revolutionizing Workplace Culture

![]()

In today’s post-pandemic landscape, characterized by an employee-centric and highly competitive market, organizations across the board are grappling with the challenges of attracting and retaining talent. The notion that “Times are changing” might sound cliche, but the reality is undeniable. We are not going back to the “good old days” of 2019. This article will give you effective strategies to keep your top talent from becoming someone else’s.

Drawing on my thirteen-year journey in industrial sales, which includes seven-years in the welding industry, combined with my current role focusing on manufacturing, construction, and skilled trades, I have had the privilege of witnessing firsthand the practices that set the most successful organizations apart. The common thread among these leading entities is their adept fusion of Gratitude and Strategy—a concept I call Grategy®. When you have a Grategy, you create a workplace where excellence thrives and loyalty is fostered.

To simplify this concept and change how we think about workplace culture, I’ve created these “Gears of Grategy.” This isn’t just another toolkit; it’s a whole new approach designed to attract and keep the best talent by fostering an environment where #positivity, #recognition, and personal #growth aren’t just buzzwords—they’re the foundation on which an organization’s culture is built.

By bringing these gears into your organization, you’re making a strong commitment to a culture that not only attracts the brightest and best but also supports them in thriving and contributing to your collective success. I’d love to hear about your journey with these gears—how have they shifted things in your company?

The Six Gears of Grategy®:

#Attitude: The Foundation: Attitude sets the stage for everything else in the Gears of Grategy®. It’s the bedrock upon which all other gears rest. Think about it: without the right attitude, nothing else truly matters. It’s about having the courage to face yourself and your business honestly, and being open to making necessary changes. When you approach challenges with a positive mindset, it’s like striking a match that ignites the enthusiasm of your team. It’s not about ignoring obstacles, but rather tackling them head-on with a focus on finding solutions. Keeping the right attitude among your team members is key—it’s what keeps everyone motivated and optimistic, shielding them from negativity.

#Attitude: The Foundation: Attitude sets the stage for everything else in the Gears of Grategy®. It’s the bedrock upon which all other gears rest. Think about it: without the right attitude, nothing else truly matters. It’s about having the courage to face yourself and your business honestly, and being open to making necessary changes. When you approach challenges with a positive mindset, it’s like striking a match that ignites the enthusiasm of your team. It’s not about ignoring obstacles, but rather tackling them head-on with a focus on finding solutions. Keeping the right attitude among your team members is key—it’s what keeps everyone motivated and optimistic, shielding them from negativity.

This foundational gear highlights the importance of fostering the right mindset to cultivate a thriving culture. Let’s be real here: without the proper mindset, your efforts will fall short. They say only babies with dirty diapers enjoy change, and let’s face it, even they aren’t thrilled about the messy process. But if you stay open to new ideas and put in the effort, you’ll witness your workplace undergo an extraordinary transformation! The beauty of attitude lies in its controllability—it’s entirely up to you. So, choose wisely, and watch as your workplace evolves into something truly remarkable!

#Appreciation: The Personal Touch of Gratitude: The second gear in the Grategy® model is appreciation, where you embrace gratitude on a personal level. My own journey with gratitude began back in 2009, and let me tell you, it’s been a game-changer in both my life and my business. It got me through tough times, especially during the recent pandemic, which hit my business hard. Gratitude isn’t just about being positive; it’s a mindset that encourages us to find the good in every situation. And here’s the kicker: there’s solid research backing it up. Gratitude isn’t some fluffy concept—it literally rewires your brain to focus on the good stuff, not to mention the physical benefits it brings. When you make gratitude a regular practice, it’s not just about feeling good; it becomes second nature to spot the positives, even in the toughest of times.

#Appreciation: The Personal Touch of Gratitude: The second gear in the Grategy® model is appreciation, where you embrace gratitude on a personal level. My own journey with gratitude began back in 2009, and let me tell you, it’s been a game-changer in both my life and my business. It got me through tough times, especially during the recent pandemic, which hit my business hard. Gratitude isn’t just about being positive; it’s a mindset that encourages us to find the good in every situation. And here’s the kicker: there’s solid research backing it up. Gratitude isn’t some fluffy concept—it literally rewires your brain to focus on the good stuff, not to mention the physical benefits it brings. When you make gratitude a regular practice, it’s not just about feeling good; it becomes second nature to spot the positives, even in the toughest of times.

But wait, there’s more! Practicing gratitude extends beyond the workplace. It opens your eyes to the goodness in all aspects of life, making it easier to recognize and celebrate the unique contributions of each team member. It’s about showing genuine appreciation for their efforts and valuing their presence in your organization. Appreciation isn’t just a part of the Grategy® model; it’s woven into the very fabric of everything we do. It’s a critical tool in your leadership toolbox, enriching every interaction and fostering a culture of gratitude and acknowledgment.

#Access: Open Doors, Open Minds: Now that you’re starting with the right attitude are finding the good in your business and your life, the third gear, Access, is about making leadership approachable and accessible, creating an atmosphere where everyone feels valued and heard. When you break down the barriers between employees and management, you’re not just opening doors – you’re opening minds.

#Access: Open Doors, Open Minds: Now that you’re starting with the right attitude are finding the good in your business and your life, the third gear, Access, is about making leadership approachable and accessible, creating an atmosphere where everyone feels valued and heard. When you break down the barriers between employees and management, you’re not just opening doors – you’re opening minds.

Access isn’t just about physical accessibility; it’s about providing opportunities for personal and professional growth. That means offering robust training programs and accessible resources that empower individuals to flourish both in and out of the workplace. Because when people feel supported in their development, they bring their best selves to the table.

Gone are the days of one-size-fits-all company cultures. Today, workplaces must adapt to meet the unique needs and expectations of team members. Leaders should make themselves available to their people, actively listening to feedback, and tuning into the pulse of the workforce through “stay” interviews. These conversations offer invaluable insights into employees’ dreams, aspirations, and concerns, providing an opportunity to address them proactively and stem the risk of turnover.

By fostering open communication and accessibility, you build trust and loyalty – the cornerstones of retention. The Access gear ensures that communication flows freely in both directions, creating a culture of transparency and support that fuels employee engagement and drives organizational success.

#Applause: Recognizing and Celebrating Success: The fourth gear in the Grategy® model is #Applause. When you verbally appreciate someone, it’s like creating a beautiful memory, but when you go the extra mile with a handwritten note or letter, you create a treasure. Whether it’s shouting out big wins or cheering on small victories, publicly recognizing the efforts driving the company forward is crucial. It’s like fuel for motivation, boosting morale, and reinforcing behaviors that are key for our success.

#Applause: Recognizing and Celebrating Success: The fourth gear in the Grategy® model is #Applause. When you verbally appreciate someone, it’s like creating a beautiful memory, but when you go the extra mile with a handwritten note or letter, you create a treasure. Whether it’s shouting out big wins or cheering on small victories, publicly recognizing the efforts driving the company forward is crucial. It’s like fuel for motivation, boosting morale, and reinforcing behaviors that are key for our success.

Now, here’s the thing about recognition: personalization matters. You can use an “All About Me” sheet to find out exactly what each of your team members like. After all, there’s no one-size-fits-all approach to saying thanks. And the best part? Recognition doesn’t have to be complicated or expensive. A genuine “thank you,” a heartfelt note, or a shout-out in the company newsletter can make someone’s day. Plus, when you encourage peer-to-peer recognition, it builds camaraderie and makes everyone feel like they’re part of something special.

#ActsOfService: Contributing to a Greater Mission: The fifth gear, Acts of Service, expands the notion of gratitude beyond the workplace by integrating corporate social responsibility (#CSR) and volunteerism into your company culture. Your team wants to feel they’re part of something larger than themselves, and are making a meaningful impact. It’s essential to showcase the positive initiatives your organization undertakes to improve the community, region, or even the world. Reflect on what drew you to your industry originally. Why are you still there? What ignites your passion? Find ways to instill that sense of purpose in your team. It goes beyond job duties and compensation; you must demonstrate how their work contributes to a greater mission, fostering a sense of belonging and meaning. This gear underscores how giving back to the community can strengthen team unity, attract socially conscious talent, and build a brand that stands for more than just financial gains.

#ActsOfService: Contributing to a Greater Mission: The fifth gear, Acts of Service, expands the notion of gratitude beyond the workplace by integrating corporate social responsibility (#CSR) and volunteerism into your company culture. Your team wants to feel they’re part of something larger than themselves, and are making a meaningful impact. It’s essential to showcase the positive initiatives your organization undertakes to improve the community, region, or even the world. Reflect on what drew you to your industry originally. Why are you still there? What ignites your passion? Find ways to instill that sense of purpose in your team. It goes beyond job duties and compensation; you must demonstrate how their work contributes to a greater mission, fostering a sense of belonging and meaning. This gear underscores how giving back to the community can strengthen team unity, attract socially conscious talent, and build a brand that stands for more than just financial gains.

#Accountability: Ensuring Alignment and Continuous Improvement: Finally, Accountability, the sixth gear, ties everything together. Here, the focus shifts to ensuring the process remains ongoing rather than treating it as a one-time event. It’s a continuous journey, with mechanisms like using KPIs in place to measure success and a readiness to adjust and refine as needed. Serving as the glue that binds everything, #accountability emphasizes that moving through the gears isn’t the end goal; it’s an ongoing journey of implementation, refinement, and perpetual progress. After all, what works today may not work tomorrow, underscoring the importance of constant adjustment. This gear fosters a culture where continual improvement isn’t just welcomed but embraced, fostering ownership from both leaders and employees to sustain the momentum of the Grategy® model. Accountability doesn’t mark the end; instead, it kickstarts the process anew with each iteration, fostering an environment of continuous growth and evolution.

#Accountability: Ensuring Alignment and Continuous Improvement: Finally, Accountability, the sixth gear, ties everything together. Here, the focus shifts to ensuring the process remains ongoing rather than treating it as a one-time event. It’s a continuous journey, with mechanisms like using KPIs in place to measure success and a readiness to adjust and refine as needed. Serving as the glue that binds everything, #accountability emphasizes that moving through the gears isn’t the end goal; it’s an ongoing journey of implementation, refinement, and perpetual progress. After all, what works today may not work tomorrow, underscoring the importance of constant adjustment. This gear fosters a culture where continual improvement isn’t just welcomed but embraced, fostering ownership from both leaders and employees to sustain the momentum of the Grategy® model. Accountability doesn’t mark the end; instead, it kickstarts the process anew with each iteration, fostering an environment of continuous growth and evolution.

Why the Gears of Grategy® Matter

As you can see, the Gears of Grategy® are more than mere components of a model; they form the foundation of a workplace culture that attracts and retains top talent. In today’s world, where employees seek more than just a paycheck, these gears provide a roadmap for cultivating an environment that values, respects, and nurtures its workforce. By embracing the Gears of Grategy®, you empower your teams, enhance performance, and establish a legacy of positive #workplaceculture. For visionary leaders, the Gears of Grategy® represent more than just a strategy; they symbolize a dedication to excellence. It’s about creating a workplace where every employee feels valued, heard, and essential to the mission.

As you navigate the complexities of the modern business landscape, the Gears of Grategy® serve as a guiding light for those committed to leading with heart, #integrity, and an unwavering pursuit of excellence. Use these gears to set a new standard for what it means to be a truly exceptional place to work. If this resonates with you and you want to use these gears to set the standard for your workplace, let’s connect.

![]() Lisa (Roman) Ryan, CSP

Lisa (Roman) Ryan, CSP

Keynote Speaker, Author, Emcee. Ready to help you keep your top talent from becoming someone else’s. #Grategy

Spring Executive Retreat – Baltimore, Maryland: How to Find a $100,000 Idea

Doug Herbert President of Herbert Construction Co. Chairman, CFA Board of Directors

“Wait, say that again,” I asked.

My contractor friend explained again what he was doing in his business that was different from what we are doing in ours.

I quickly pulled out my phone and punched some numbers into the calculator.

I wanted to see how much we could reduce our costs by doing it his way. I pushed the “equals” button and couldn’t believe what it said…

$100,698.49

One hundred thousand dollars?! For a better safety initiative at our company?!

Holy cow. This is huge.

I stood there in shock for a moment. I was with a group of CFA members touring my friend’s Maryland facility during the CFA Spring Executive Retreat this past April.

We had all come from different parts of the country to visit Jim Bartley’s company, Bartley Corp., in the morning. Then, in the afternoon, we toured the facilities of Modern Foundations, led by Bruce, Jason, and Michael Neale.

During the two-day event, we also held our quarterly Board Meeting, took an incredible tour of the U.S. Naval Academy, and ate great food.

But the main reason for all of us to attend was to learn about fellow CFA members’ businesses to help our own.

And here I was, halfway through the first company tour and I had already found a way to save $100,000 per year at our company. It was awesome!

Ideas to Implement

At Herbert Construction, we’ve been learning from CFA members like this for over 30 years. Constant improvement is a big thing at our company. We will often travel to fellow members’ offices to tour and dissect their company.

I’ll admit, we don’t often find a $100k idea. But we always walk away with something that can improve our company. And, hopefully, leave them with something that’ll improve theirs.

A Small Bracket for a Big Project

At the Fall Executive Retreat in Oklahoma City last year, CFA members toured some job sites of contractor member Mike Hancock of Basement Contractors. At one job site, Mike showed me a special bracket he made for forming tall walls.

A tour of the U.S. Naval Academy was the surprise networking event.

With Mike’s permission, I snapped a bunch of photos and took the dimensions of the bracket for our use. In the next two weeks, we’ll use a variation of Mike’s bracket on a $1million+ foundation with 32’-0” tall walls. Thanks to Mike’s bracket, we won’t tie up as many forms while the project is underway. And, we’ll finish the project faster. Cha-ching!

Four Yearly Events

The CFA hosts four main events each year. The largest event is the Convention. Held in the Summer at a different location each year, this is the place to be for residential concrete contractors. It is filled with terrific speakers, valuable vendors, and fun activities. This year’s event will be held in Puerto Rico and it’s going to be outstanding. (FYI: If you haven’t already reserved your room at the resort, then do it now because it’s going to sell out early.)

During the World of Concrete Convention in Las Vagas, the CFA hosts its Winter Social. If you’ve attended that event recently, you know how exciting it is.

Then, in the Spring and Fall, the CFA invites members to its Executive Retreat. Each event takes place near a member’s facility. This can be an associate member who can host a plant tour. Or, it can be a contractor member who will open up their business and share what they are doing for the benefit of the attendees.

Founding member of the CFA and of Bartley Corp, Buck Bartley regales the history of the Association.

A record attendance for CFA Executive Retreats as the group wrapped up the US Naval Academy tour

As you can tell from my experiences, these Executive Retreats are incredibly valuable.

I’d encourage you to get involved in any or all these four CFA yearly events. Meet new members. Ask dumb questions. Keep your mind open to alternative ways of doing things. And share what you know.

You’ll be amazed at what you can get out of it.

And just maybe, you’ll get a $100,000 idea.

Michael Neale of Modern Foundations and MFI Concrete holds court during a tour of facilities to explain their quality control requirements for precast operations