Cru Concrete Gives High School Students Hands-On Learning about Rewarding Careers in Concrete Construction

The American construction industry is one of the largest in the world, with a commitment to quality, safety and longevity. And within the United States, Wisconsin stands out as a great place to be a construction worker. According to the Associated Builders and Contractors’ 10th annual Merit Shop Scorecard released in December 2024, Wisconsin ranks number one in the country for construction. This annual scorecard looks at all fifty states’ taxpayer-funded construction projects and evaluates policies and programs that further workforce development and careers in construction. This high rating means that an increasing number of young people in the Midwest are choosing to pursue careers in construction straight from high school instead of going to two-year or four-year colleges.

For students who are interested in entering the construction field but are unsure whether it’s a good fit for them, trade and industry programs at the high school level are a great way to test the waters to see not just whether a career in construction is right for them, but which specific field interests them the most.

For the past six years, CFA Certified Contractor and member Cru Concrete (formerly Hottmann Construction) of Dane and Waukesha, Wisconsin, has been a proud participant in the Franklin High School’s Advanced Construction class’ house build project. Students from Franklin High School work together with the Cru Concrete crews, learning from experts and helping with every step of the concrete-laying process. This includes installing and removing forms, pouring footings and walls, and completing the many steps involved in the flatwork process.

Franklin teacher Andrew Mente, who introduced and oversees the program, explains how a house-building project that’s part of this program works. “Our Advanced Construction class collaborates with Tim O’Brien builders to give our students a spec home where we can be a part of the entire house build. Students get to be hands-on from foundation to finish, working side by side with the contractors. They get real-world on the jobsite experience and get to meet and work with twenty-plus tradespeople.”

Interest in the program continues to grow and garner attention. CBS channel 58 (WDJT-TV) out of Milwaukee featured an in-depth look at the program in October 2024 on their Sunday Morning news. There is currently a waitlist of interested students and a rising amount of interest from female students. Nearly half of the program’s current students are female, which is a sharp increase from years past.

Student participant Emily Engel feels the program has given her “a chance to discover new career paths.” Though her focus is more on the electrical field, she sees value in understanding the whole process of how a home is constructed.

Even students who are not considering careers in construction find they have a lot to learn from the program. Miranda Gander, a Franklin senior who plans to attend the University of Wisconsin -Stout in Menomonie in fall 2025 for industrial and product design, explains how participating in this program will help her in her future career: “It’s really helpful to see all different aspects of people’s jobs so that I can create products eventually that benefit the homeowner.”

Mente shares, “Working with Cru is a great time for the students because they let the kids get ankle-deep in concrete, placing forms and floating finish. It’s impossible for me as a teacher to recreate that experience at school, so getting them onto actual job sites teaches them so many things they can’t get in a lab.”

Some students start out thinking a construction career is for them, but the program causes them to reconsider, or to at least shift their focus from one type of construction to another. Other students go into the program expecting to like it and find they love it. These are all wins, because ultimately the goal is to match the right workers with the right careers so strong, lasting partnerships can develop.

For students who try out the program and are drawn to concrete construction as a career choice, there are opportunities for apprenticeships or, in the case with Cru, getting hired and being provided with on-the-job training. As Mente says, “It’s a great collaboration that benefits both groups and helps make a pipeline for students interested in the trades.” For those students who go through the program and are hired by Cru, they have a clear and direct route to a stable, well-paying career that typically offers plenty of room for growth and advancement. Few jobs can offer that to an 18- or 19-year-old just starting out. But at Cru, many of the executives, including owner Ken Kurszewski, began their careers out in the field and worked their way up.

“Working with Andrew and his Advanced Construction class has been an incredibly rewarding experience,” says Mike Swift, General Manager at Cru Concrete. “Each year, we look forward to engaging with the students and introducing them to the world of concrete construction. Many high school juniors and seniors are still exploring potential career paths, and this is a unique opportunity for us to show them how they can build a rewarding future here at Cru Concrete.”

Ultimately, this program is about collaboration, with all involved benefiting. Cru Concrete is proud to be a part of this collaboration and looks forward to many more years of working with Franklin High School students.

SOURCES

https://www.abc.org/News-Media/News-Releases/abc-wisconsin-is-the-top-state-for-construction

https://www.cbs58.com/news/this-is-our-classroom-franklin-high-school-students-learn-on-the-job-site

Interviews with Andrew Mente, Emily Engel, and Miranda Gander

2025 CFA Projects of the Year Opens for Evaluations

FOR IMMEDIATE RELEASE

Concrete Foundations Association Invites Public to Score 2025 “Projects of the Year” Finalists

Mount Vernon, IA – June 9, 2025 – The Concrete Foundations Association (CFA) is excited to announce the public evaluation period is now open for its 2025 “Projects of the Year” competition. This annual program highlights some of the most impressive and technically challenging cast-in-place concrete foundation projects in the residential and light commercial market—and now, the public has the opportunity to help choose the winners.

🏆 What Is It?

Each year, CFA members submit their best projects to be judged by a panel of industry professionals, with finalists selected across a variety of categories. The final stage invites the broader community—builders, contractors, designers, and enthusiasts—to view and evaluate the finalists based on quality, complexity, creativity, and execution.

🗳 How to Participate:

Public scoring takes approximately one hour and can be completed online at:

👉 https://freeonlinesurveys.com/s/ZSUwa85J

Each entry includes detailed descriptions and photos so participants can make informed evaluations. The public’s input is combined with peer review scoring to determine the overall winners.

Why It Matters:

- Recognizes Excellence – These projects represent the best in concrete foundation craftsmanship and innovation.

- Inspires the Industry – From complex foundation systems on sloped lots to decorative above-grade concrete, these entries showcase the versatility and strength of poured concrete solutions.

- Supports Skilled Labor – Every vote helps honor the crews, companies, and engineers behind these outstanding projects.

About the Competition:

Now in its 26th year, the CFA “Projects of the Year” competition receives submissions from across North America. Categories include small to large residential foundations, commercial/multi-family work, decorative concrete, and non-foundation structural elements. Winners are featured in Concrete Facts magazine and honored at the CFA Summer Meeting. Evaluation for the projects submitted ends at 11:59 pm on June 12th. Projects will be publicly announced during the Association’s signature event, CFACON25 in Deadwood, South Dakota (July 17-19) during the Kick-Off Bash and Awards Gala on Thursday, July 17th.

About the CFA:

Now in its 50th year, the Concrete Foundations Association is the leading nonprofit organization representing cast-in-place concrete contractors. With a mission to support professionalism, safety, and technical advancement, CFA serves as the industry’s voice and resource hub.

Now in its 50th year, the Concrete Foundations Association is the leading nonprofit organization representing cast-in-place concrete contractors. With a mission to support professionalism, safety, and technical advancement, CFA serves as the industry’s voice and resource hub.

Learn More:

Explore past winners and learn more about how to participate in this members-only competition at www.cfaconcretepros.org or www.concretefactsmagazine.com.

Media Contact:

James Baty, Executive Director

Concrete Foundations Association

Email: info@cfaconcretepros.org

Phone: (319) 895-6940

— END —

La Edición Primavera 2025 de la Revista Concrete Facts ya Disponible en Español

La Concrete Foundations Association (CFA) se complace en anunciar la edición en español de la última publicación de su revista sectorial, Concrete Facts. Publicada trimestralmente tanto en inglés como en español, Concrete Facts ofrece valiosos conocimientos , experiencia técnica y actualizaciones de la industria para los profesionales de concreto que hablan inglés o español en toda América del Norte y más allá.

Según James Baty, Director Ejecutivo de la CFA, publicando la revista en español abre las puertas a un mayor acceso a conocimientos esenciales, mejores prácticas de seguridad y las últimas tendencias de la industria. A continuación, se presentan las características clave de la edición en español de Concrete Facts, disponible en línea como un libro interactivo de páginas volteables:

- Experiencia de la industria en español: Accede a artículos técnicos, mejores prácticas en el campo y estrategias empresariales diseñadas específicamente para el sector del concreto, presentados en español.

- Recursos prácticos para profesionales de la construcción: Los temas incluyen seguridad, técnicas listas para el campo, innovaciones en el lugar de trabajo y casos de éxito reales para ayudar a los equipos de habla hispana a sobresalir.

- Empoderando a los propietarios de empresas hispanohablantes: Mantente al día con los cambios en normativas, avances tecnológicos y oportunidades de mercado que están dando forma a la industria del concreto.

- Para contratistas con equipos diversos: Mejora la comunicación en el lugar de trabajo y la capacitación con contenido que elimine las barreras lingüísticas, fortaleciendo tu empresa desde adentro.

- Cobertura integral: Desde la resiliencia en la construcción y desarrollo de liderazgo hasta la gestión de proyectos y noticias de la asociación, cada edición ofrece orientaciones prácticas.

Además de la opción del libro interactivo, los artículos en inglés y español están disponibles de forma gratuita en el sitio web de Concrete Facts en https://concretefactsmagazine.com/, asegurando que el contenido valioso llegue a todos los rincones de la industria.

“Reconocemos la importancia de tener nuestro contenido disponible tanto en español como en inglés”, -dijo Baty. “Nuestro objetivo en las próximas ediciones es encontrar nuevas formas de capturar las historias de nuestros líderes de la industria de hable hispana para que la voz de CFA para los contratistas de concreto in situ de hoy realmente dé voz y reconocimiento a todos”.

Accede a la última edición y explora artículos recientes en español e inglés de forma gratuita en https://concretefactsmagazine.com/.

Concrete Facts Magazine Spring 2025 Issue Now Available in Spanish

The Concrete Foundations Association (CFA) is excited to highlight the Spanish-language edition of the latest issue of its industry magazine, Concrete Facts. Released quarterly in both English and Spanish, Concrete Facts delivers high-value insights, technical expertise and industry updates to English- and Spanish-speaking concrete professionals across North America and beyond.

According to James Baty, Executive Director of CFA, publishing the magazine in Spanish opens the doors for greater access to vital knowledge, safety best practices and the latest industry trends. Following are key features of the Concrete Facts Spanish Edition, which is available online as an interactive flipbook:

- Industry expertise in Spanish: Get access to technical articles, field best practices and business strategies designed specifically for the concrete sector, delivered in Spanish.

- Practical resources for construction professionals: Topics cover safety, field-ready techniques, jobsite innovations and real-world success stories to help Spanish-speaking teams excel.

- Empowering Spanish-speaking business owners: Stay up to date with evolving regulations, technological advances and market opportunities shaping the concrete industry.

- For contractors with diverse teams: Enhance workplace communication and training with content that bridges language gaps, strengthening your company from within.

- Comprehensive coverage: From resilience in construction and leadership development to project management and association news, every issue provides actionable guidance.

In addition to the flipbook option, both English and Spanish articles are also freely accessible via the Concrete Facts website at https://concretefactsmagazine.com/, ensuring valuable content reaches every corner of the industry.

“We recognize the importance of having our content available in both Spanish and English,” said Baty. “Our goal in the coming issues is to find new ways to capture the stories of our Spanish-speaking industry leaders so that CFA’s voice for today’s cast-in-place contractor truly does give voice and recognition to all.”

Access the latest issue and browse recent articles in Spanish and English for free at https://concretefactsmagazine.com/.

How to Rewire Your Brain for Success

The human brain is incredibly adaptable. It holds the potential to change, learn and grow throughout our lives. However, many people unknowingly sabotage this by operating with a fixed mindset, the belief that abilities and intelligence are static. Research shows that this mindset limits personal and professional success, as well as discourages positive change. On the other hand a growth mindset, the belief that skills can be developed, unlocks boundless possibilities.

Do you feel stuck, unmotivated or frustrated by repeated challenges? Maybe you find yourself resisting new experiences or feeling overwhelmed and burnt out by stress. These are just a few of the symptoms of a fixed mindset.

The key to shifting from a fixed to a growth mindset is in the chemistry of our brains. The chemicals dopamine, serotonin, endorphins and oxytocin all play a role in our motivation, emotional resilience and adaptability. If your brain has lower levels of these chemicals, change becomes a challenge. However, adding some simple self-care practices to your life can increase these neurotransmitters and prime your brain for growth.

Eight Strategies to Rewire Your Brain

- Improve Your Sleep Habits: Sleep is foundational for mental and physical health. During sleep, the brain clears toxins, consolidates memories and prepares for new learning. Aim for seven to nine hours of consistent, high-quality sleep by establishing a bedtime routine, avoiding screens before bed and creating a relaxing sleep environment.

- Eat for Brain Health: Nutrition profoundly impacts the brain. A diet rich in fruits, vegetables, lean proteins and complex carbohydrates supports the production of neurotransmitters like serotonin. Avoid processed foods and added sugars, as they can disrupt your gut microbiome and negatively affect mood and cognitive function. Even small dietary changes, such as reducing sugar or increasing fiber intake, can make a noticeable difference.

- Get Moving: Regular physical activity boosts endorphins, reduces stress and improves overall brain function. Even moderate exercise like walking, swimming or yoga, oxygenates the brain and strengthens its adaptability. Consistency is key, so find a form of movement that feels enjoyable and sustainable.

- Practice Mindful Focus: Constant distractions diminish focus and productivity. Train your brain by practicing mindfulness or meditation. Focus on one task at a time and take periodic breaks from technology to recalibrate your attention. Even five minutes a day of deep breathing or intentional concentration can improve your ability to manage stress and improve clarity.

- Calm Your Mind: Chronic stress impairs the brain’s ability to adapt and grow. Counteract stress by engaging in calming activities like nature walks, deep breathing exercises or journaling. Quiet moments allow the brain to reset and process information more effectively. Immersing yourself in peaceful surroundings, such as a park or forest, can significantly lower cortisol levels and foster a sense of well-being.

- Embrace New Experiences: Novel experiences stimulate neuroplasticity by challenging the brain to form new connections. Learning a new skill, taking up a hobby or exploring a creative activity all encourage growth and adaptability in your brain. Whether it’s learning to cook, play an instrument or paint, pushing yourself to try something unfamiliar keeps your brain active and flexible.

- Cultivate Gratitude: Gratitude directly impacts brain chemistry by increasing dopamine and serotonin levels. Start a daily gratitude journal to focus on the positive aspects of your life. This simple practice shifts your perspective toward growth. Gratitude also enhances your relationships, which strengthens social bonds and further supports emotional health.

- Engage Your Senses: Deep observation helps you become more present and aware of the world around you. Take time to fully engage your senses, whether it’s savoring the taste of food, listening to the sounds of nature or noticing details in your surroundings. This practice promotes mindfulness, stimulates curiosity and encourages a sense of wonder about the world.

The Growth Journey Starts Now

Rewiring your brain is not an overnight process. It requires discipline, rigor and the development of the right habits. By incorporating even just a few of these self-care strategies into your life, you’ll create the foundation for sustained personal and professional growth.

Start with one practice today and commit to building from there. Small, consistent changes lead to significant transformations over time. Embrace the journey and watch your mindset shift from thinking about what isn’t possible to everything that is possible.

Having an open mindset is a necessity. An open mindset encourages innovation, strengthens relationships and helps us navigate change with confidence. On the other hand, holding onto rigid beliefs or outdated views can lead to missed opportunities and stalled growth. In a world that rewards flexibility, a closed mind can hold you back more than ever before. With rapid advancements in technology, shifting social landscapes and global challenges, those who stay curious, adaptable and open to new ideas are the ones who thrive.

About the Author:

Margaret Graziano, known as the Evolutionist, is the founder and CEO of KeenAlignment, as well as a Wall Street Journal Best-Selling Author for her book Ignite Culture. She has been recognized as one of Silicon Valley’s Top 100 Women Leaders. Margaret’s groundbreaking work is driven by her power to uncover and catalyze human potential. Go to www.MargaretGraziano.com for more information.

Caught in Action

Often, the menial tasks of the construction environment go unnoticed or unrewarded. Contractors tend to consider the major schedule stages and the completion of the project in general as the time to appreciate overall accomplishments. Yet, thriving company cultures are built on identifying the important in-between steps. In January, The Bartley Corporation demonstrated this value, declaring, “Shoutout to our amazing team for working hard through the snowiest and windiest of conditions.”

“We know our guys do quality work, but I find it most rewarding to see them attack the jobs that no one else would want,” states Jim Bartley, President of Bartley Corp. “We don’t get a lot of snow in Maryland, but when we get a storm like this, it can severely wreck our schedule. This photo showed the creativity of using everything at their disposal and all hands on deck to keep us running on schedule with safety and quality. We are very proud of the work Hector Linares and Francis Perdomo, both pictured, as well as Jorge Castillo on the crane, not in the picture, and Alex Alfaro-Yanes wielding the big shovel in the foreground.”

Do you have photos of exceptional work or aspects of your business “caught in action” you would like to nominate? Send them directly to CFA Executive Director, James Baty, at jbaty@cfaconcretepros.org.

Atrapado en acción

A menudo, las tareas no especializadas del entorno de la construcción pasan desapercibidas o sin recompensas. Los contratistas tienden a considerar las principales etapas del calendario y la finalización del proyecto en general como el momento de apreciar los logros comunes. Sin embargo, las culturas empresariales prósperas se construyen con la identificación de los pasos intermedios importantes. En enero, The Bartley Corporation demostró este valor declarando: «Enhorabuena a nuestro increíble equipo por la dedicación en las condiciones con más nieve y viento».

«Sabemos que nuestros chicos hacen un trabajo de calidad, pero para mí lo más gratificante es verles acometer los trabajos que nadie más querría», afirma Jim Bartley, Presidente de Bartley Corp. «En Maryland no nieva mucho, pero cuando cae una tormenta como esta, puede destrozarnos seriamente el calendario. Esta fotografía demostró la creatividad de utilizar todo lo que tenían a su disposición y la ayuda de todas las personas para mantenernos en funcionamiento según lo previsto con seguridad y calidad. Estamos muy orgullosos del trabajo de Héctor Linares y Francis Perdomo, ambos en la fotografía, además de Jorge Castillo en la grúa, que no aparece en la fotografía, y de Alex Alfaro-Yanes empuñando la gran pala en primer plano».

¿Tiene fotos de un trabajo excepcional o de aspectos de «atrapados en acción» de su empresa que le gustaría nominar? Envíelas directamente al Director Ejecutivo de la CFA, James Baty, a jbaty@cfaconcretepros.org.

Cómo reconectar el cerebro para el éxito

De Margaret Graziano

El cerebro humano es increíblemente adaptable. Tiene el potencial de cambiar, aprender y crecer a lo largo de nuestra vida. Sin embargo, la creencia de que las habilidades y la inteligencia son estáticas hace que muchas personas lo saboteen sin saberlo actuando con una mentalidad fija. Los estudios demuestran que esta mentalidad limita el éxito profesional y personal, y desalienta el cambio positivo. En cambio, una mentalidad de crecimiento, la creencia de que las habilidades pueden desarrollarse, abre posibilidades ilimitadas.

¿Se siente estancado, desmotivado o frustrado por los retos repetidos? Tal vez se resista a las nuevas experiencias o se sienta abrumado y agotado por el estrés. Estos son solo algunos de los síntomas de una mentalidad fija.

La clave para pasar de una mentalidad fija a una mentalidad de crecimiento está en la química de nuestro cerebro. Las sustancias químicas dopamina, serotonina, endorfinas y oxitocina intervienen en nuestra motivación, resistencia emocional y adaptabilidad. Si su cerebro tiene niveles bajos de estas sustancias químicas, el cambio se convierte en un reto. Sin embargo, añadir algunas prácticas sencillas de autocuidado a su vida puede aumentar estas sustancias químicas y preparar su cerebro para el crecimiento.

Ocho estrategias para reconectar el cerebro

- Mejorar los hábitos de sueño: El sueño es fundamental para la salud física y mental. Durante el sueño, el cerebro elimina toxinas, consolida recuerdos y se prepara para nuevos aprendizajes. Tenga como objetivo dormir entre siete y nueve horas de forma constante y de alta calidad estableciendo una rutina a la hora de acostarse, evitando las pantallas antes de ir a la cama y creando un entorno relajante para dormir.

- Comer para la salud cerebral: La nutrición tiene un profundo impacto en el cerebro. Una dieta rica en frutas, verduras, proteínas magras y carbohidratos complejos favorece la producción de neurotransmisores como la serotonina. Evite los alimentos procesados y los azúcares añadidos, ya que pueden alterar el microbioma intestinal y afectar de forma negativa al estado de ánimo y la función cognitiva. Incluso pequeños cambios en la dieta, como reducir el azúcar o aumentar la ingesta de fibra, pueden marcar una diferencia perceptible.

- Ponerse en movimiento: La actividad física regular estimula las endorfinas, reduce el estrés y mejora la función cerebral en general. Incluso el ejercicio moderado, como caminar, nadar o hacer yoga oxigena el cerebro y refuerza su capacidad de adaptación. La constancia es clave, así que encuentre una forma de movimiento que le resulte agradable y sostenible.

- Practicar la atención plena: Las distracciones constantes disminuyen la concentración y la productividad. Entrene el cerebro practicando la atención plena o la meditación. Concéntrese en una tarea cada vez y haga descansos regulares de la tecnología para recalibrar su atención. Incluso cinco minutos al día de respiración profunda o concentración intencional pueden mejorar su capacidad para manejar el estrés y mejorar la claridad.

- Calmar la mente: El estrés crónico afecta la capacidad del cerebro para adaptarse y crecer. Contrarreste el estrés realizando actividades tranquilizantes como paseos por la naturaleza, ejercicios de respiración profunda o escribir un diario. Los momentos de tranquilidad permiten al cerebro cambiar y procesar la información con mayor eficacia. Sumergirse en un entorno tranquilo, como un parque o un bosque, puede reducir significativamente los niveles de cortisol y alimentar una sensación de bienestar.

- Aprovechar las nuevas experiencias: Las experiencias novedosas estimulan la neuroplasticidad desafiando al cerebro a formar nuevas conexiones. Aprender una nueva habilidad, dedicarse a un pasatiempo o explorar una actividad creativa incentivan el crecimiento y la adaptabilidad del cerebro. Ya sea aprender a cocinar, tocar un instrumento o pintar, abrirse paso a probar algo desconocido mantiene el cerebro activo y flexible.

- Cultivar la gratitud: La gratitud tiene un efecto directo en la química cerebral aumentando los niveles de dopamina y serotonina. Comience a escribir un diario de gratitud todos los días para centrarse en los aspectos positivos de su vida. Esta sencilla práctica cambia su perspectiva hacia el crecimiento. La gratitud también mejora sus relaciones, fortaleciendo los lazos sociales y apoya aún más la salud emocional.

- Involucrar los sentidos: La observación profunda le ayuda a estar más presente y ser más consciente del mundo que le rodea. Dedique tiempo a involucrar completamente sus sentidos, ya sea saboreando la comida, escuchando los sonidos de la naturaleza o prestando atención a los detalles de su entorno. Esta práctica promueve la atención plena, estimula la curiosidad e incentiva un sentido de asombro sobre el mundo.

El viaje hacia el crecimiento comienza ahora

Reconectar el cerebro no es un proceso que se haga de la noche a la mañana. Requiere disciplina, rigor y el desarrollo de los hábitos adecuados. Al incluir en su vida algunas de estas estrategias de autocuidado, sentará las bases de un crecimiento personal y profesional sostenido.

Reconectar el cerebro no es un proceso que se haga de la noche a la mañana. Requiere disciplina, rigor y el desarrollo de los hábitos adecuados. Al incluir en su vida algunas de estas estrategias de autocuidado, sentará las bases de un crecimiento personal y profesional sostenido.

Comience hoy mismo con una práctica y comprométase al desarrollo desde ahí. Los cambios pequeños y constantes conducen a transformaciones significativas con el paso del tiempo. Acepte el viaje y observe cómo su mentalidad cambia de pensar en lo que no es posible a todo lo que sí es posible.

Tener una mentalidad abierta es una necesidad. Una mentalidad abierta incentiva a la innovación, fortalece las relaciones y nos ayuda a hacernos camino por el cambio con confianza. Por otro lado, aferrarse a creencias rígidas o puntos de vista anticuados puede conducir a la pérdida de oportunidades e impedir el crecimiento. En un mundo que recompensa a la flexibilidad, una mentalidad cerrada puede frenarle más que nunca. Con los rápidos avances tecnológicos, panoramas sociales cambiantes y los retos globales, aquellos que se mantienen curiosos, adaptables y abiertos a nuevas ideas son los que prosperan.

Acerca de la autora:

Margaret Graziano, conocida como la Evolucionista, es la fundadora y Directora general de KeenAlignment, además de una de las autoras con más ventas según el Wall Street Journal por su libro Ignite Culture. Ha sido reconocida como una de las 100 mujeres líderes de Silicon Valley. El trabajo innovador de Margaret está impulsado por su poder para descubrir y catalizar el potencial humano. Visite www.MargaretGraziano.com para obtener más información.

Margaret Graziano, conocida como la Evolucionista, es la fundadora y Directora general de KeenAlignment, además de una de las autoras con más ventas según el Wall Street Journal por su libro Ignite Culture. Ha sido reconocida como una de las 100 mujeres líderes de Silicon Valley. El trabajo innovador de Margaret está impulsado por su poder para descubrir y catalizar el potencial humano. Visite www.MargaretGraziano.com para obtener más información.

¿Cómo define la estabilidad en su empresa de concreto?

De Bill Humbert, www.RecruiterGuy.com

Nuestro país está evolucionando: cambian las perspectivas, se ajustan las políticas de inmigración e incluso se está remodelando el tamaño de nuestro gobierno. Como en cualquier transformación, habrá resistencia y consecuencias imprevistas. Algunos de estos cambios pueden tener un impacto positivo en su empresa, mientras que otros pueden plantear retos. Este artículo no pretende alarmarle, sino suscitar un razonamiento analítico sobre cómo estos cambios podrían afectar a su empresa de concreto.

Nuestro país está evolucionando: cambian las perspectivas, se ajustan las políticas de inmigración e incluso se está remodelando el tamaño de nuestro gobierno. Como en cualquier transformación, habrá resistencia y consecuencias imprevistas. Algunos de estos cambios pueden tener un impacto positivo en su empresa, mientras que otros pueden plantear retos. Este artículo no pretende alarmarle, sino suscitar un razonamiento analítico sobre cómo estos cambios podrían afectar a su empresa de concreto.

«A veces, veo las cosas de otra manera…» Ese es el lema de las Cartas al Editor de mi sitio web. Así pues, veamos de otra forma la estabilidad en los negocios.

¿Se trata de mantener el mismo plan?

Cuando hablo con propietarios de pequeñas empresas sobre estrategia, a menudo escucho:

“Sé lo que hago. ¡Mi empresa ha tenido éxito todos los años! ¡Es sólida como una roca!”

O, en su caso, tal vez “sólida como una zapata de concreto”.

Eso me hizo pensar: ¿la estabilidad significa ejecutar el mismo plan de negocio año tras año, independientemente de los cambios del mercado?

Consideremos algo importante: las rocas no crecen. Con el tiempo, se erosionan; basta con ver el Gran Cañón.

¿Qué pasaría si su empresa fuera un roble?

En lugar de pensar en su empresa como una roca, ¿qué pasaría si la viera como un roble?

- Raíces profundas: Su experiencia y conocimiento del sector proporcionan una base sólida.

- Resistencia: Como la madera de roble, su empresa puede resistir tormentas y cambios en el mercado.

- Firmeza: La corteza del árbol lo protege de las plagas, igual que su capacidad de adaptación le protege de los retos del mercado.

- Longevidad: Los robles pueden vivir cientos de años. Aunque eso no sea cierto para usted, su empresa puede prosperar durante generaciones.

- Crecimiento oportunista: Los robles se ramifican hacia el sol, intuyendo dónde expandirse para obtener la máxima ventaja.

¿La diferencia clave? Un roble crece y se adapta. ¿Su empresa no debería hacer lo mismo?

¿Cómo puede diversificar su empresa de concreto?

Piense en cambios pequeños e impactantes para mejorar la rentabilidad sin una inversión de capital significativa.

- ¿Dónde puede eliminar ineficiencias y liberar tiempo?

- ¿Qué partes de su empresa le proporcionan la mayor rentabilidad del esfuerzo?

- ¿Sería más feliz y rentable realizando presupuestos o elaborando un plan estratégico de crecimiento?

- Si la realización de presupuestos le quita demasiado tiempo de marketing y ventas, ¿sería más sensato contratar a un asesor? Podría estar haciendo crecer su empresa mientras su asesor saca punta a sus lápices.

Desde que inicié mi empresa en 1990, no he dejado de adaptarme. No me limité a lo que funcionaba, sino que me diversifiqué. Así es cómo diversifiqué mis ingresos:

- Autoría de libros: He escrito tres libros de búsqueda de empleo y he promovido activamente su venta.

- Conferencias internacionales: Me arriesgué a dar charlas sobre El poder de establecer objetivos adecuados en tres continentes.

- Ampliación de mi experiencia: Mi cuarto libro, de próxima publicación, generará ingresos adicionales a través de las ventas en sala.

También invertí en un coach para que me ayudara a elaborar estrategias y ejecutar con éxito estas nuevas oportunidades.

La única constante es el cambio: ¿cómo va a responder?

No podemos controlar los grandes cambios culturales y económicos, pero sí podemos controlar cómo respondemos a estos. Los líderes empresariales con más éxito no sólo capean el temporal, sino que se adaptan, crecen y superan a la competencia.

Me encantaría conocer sus retos. Hablemos, exploremos nuevas posibilidades y construyamos un camino más fuerte y resistente para su empresa.

Es fácil reunirse conmigo cuando más le convenga. Haga clic en este enlace para encontrar un horario que nos venga bien a los dos – www.recruiterguy.com/contact/

¡ANTICIPE EL ÉXITO!

Volver a construir mejor: A favor de las viviendas de concreto

De Joe Nasvik

Los recientes incendios de Los Ángeles provocaron la mayor cantidad de daños por fuego jamás vista en el país. Para muchas personas, la vida pasó de la normalidad a la desesperación absoluta en cuestión de horas. Casas de todo tipo, desde modernas y tradicionales, nuevas y viejas, con revestimiento de estuco, con techos de teja y de acero hasta pequeñas y grandes, se redujeron a cenizas, dejando a las personas sin hogar ni posesiones. Con el paso del tiempo, la investigación descubrirá muchos factores contribuyentes, pero sin duda las dos causas principales de los incendios fueron la falta de lluvia en la cuenca de Los Ángeles durante el año pasado y los vientos de Santa Ana de hasta 100 millas por hora con solo un 3 % de humedad que avivaron los incendios e hicieron casi imposible la extinción del fuego. El otro factor clave es el hecho de que las viviendas destruidas estaban construidas con materiales combustibles.

Creas o no personalmente en el calentamiento global o consideres o no que está causado por el hombre, es un hecho que el clima está cambiando en todo el mundo y que las temperaturas globales aumentan. Con más de medio millón de años de historia meteorológica recopilada, la investigación científica ha demostrado la relación entre el dióxido de carbono (CO2) en el aire y la temperatura atmosférica. Cuando los niveles de CO2 en el aire aumentan, también aumenta la temperatura atmosférica, y cuando descienden la temperatura también desciende. La cuestión que queda por resolver es dónde se crea el CO2. Con el aumento de la energía térmica en la atmósfera, las condiciones meteorológicas seguirán siendo más extremas y, como resultado, las estructuras de nuestros edificios tendrán que ser más robustas.

Cuando Los Ángeles esté lista para la reconstrucción, habrá códigos de la edificación actualizados diseñados para ofrecer mejor protección en caso de incendio. Por el bien de los que fallecieron y de los que lo perdieron todo, es hora de que los códigos de la edificación exijan que todas las casas nuevas se construyan con materiales ignífugos o, como mínimo, que los edificios sean estructuralmente sólidos durante una hora o más en un entorno de incendio. El código de la construcción de la ciudad de Los Ángeles probablemente exigirá diseñar que las casas no atrapen rescoldos ardientes cuando sople el viento, se reduzcan los materiales de jardinería inflamables alrededor de las casas y se modifiquen los sistemas de abastecimiento de agua. También es probable que se ensanchen las calles estrechas para que los vehículos que salgan de una zona no interfieran con los vehículos de emergencia que se dirijan en sentido contrario. Las actualizaciones del código de la edificación probablemente exigirán también que los edificios se diseñen para resistir vientos más fuertes y condiciones meteorológicas violentas, en reconocimiento del cambio climático.

Cuando Los Ángeles esté lista para la reconstrucción, habrá códigos de la edificación actualizados diseñados para ofrecer mejor protección en caso de incendio. Por el bien de los que fallecieron y de los que lo perdieron todo, es hora de que los códigos de la edificación exijan que todas las casas nuevas se construyan con materiales ignífugos o, como mínimo, que los edificios sean estructuralmente sólidos durante una hora o más en un entorno de incendio. El código de la construcción de la ciudad de Los Ángeles probablemente exigirá diseñar que las casas no atrapen rescoldos ardientes cuando sople el viento, se reduzcan los materiales de jardinería inflamables alrededor de las casas y se modifiquen los sistemas de abastecimiento de agua. También es probable que se ensanchen las calles estrechas para que los vehículos que salgan de una zona no interfieran con los vehículos de emergencia que se dirijan en sentido contrario. Las actualizaciones del código de la edificación probablemente exigirán también que los edificios se diseñen para resistir vientos más fuertes y condiciones meteorológicas violentas, en reconocimiento del cambio climático.

El cambio a materiales de construcción ignífugos no será fácil. Históricamente, Estados Unidos ha tenido la suerte de contar con grandes bosques, por lo que nos hemos convertido en una cultura de la construcción con madera, con una gran mano de obra cualificada para construir estructuras de madera. Sin embargo, este no es el caso de muchos otros países del mundo donde la madera es escasa. En esos lugares, el concreto es el principal material de construcción. En Florida se construyen más casas de concreto que en ningún otro estado debido a los daños causados por los huracanes, las inundaciones, las termitas y un clima que favorece el deterioro de la madera.

Viviendas de concreto

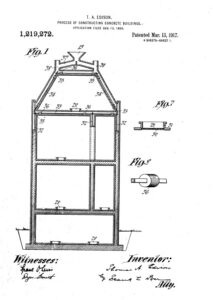

La presión por el uso del concreto en Estados Unidos tiene una larga historia. En 1908, Thomas Edison inició la solicitud de una patente para la construcción de casas de concreto. Desarrolló encofrados de hierro fundido que se ensamblaban para construir una vivienda completa en una sola colocación de concreto. Se dejó una abertura en la parte superior del tejado para que el concreto entrara en los encofrados. También desarrolló una mezcla fluida para que el concreto llegara hasta la parte inferior de la vivienda y a todas las partes del encofrado. Luego, los encofrados se desarmaban y se trasladaban a la siguiente vivienda. Solo construyó unas pocas casas en Nueva Jersey y Gary, Indiana, y algunas de ellas siguen en uso hoy en día.

La presión por el uso del concreto en Estados Unidos tiene una larga historia. En 1908, Thomas Edison inició la solicitud de una patente para la construcción de casas de concreto. Desarrolló encofrados de hierro fundido que se ensamblaban para construir una vivienda completa en una sola colocación de concreto. Se dejó una abertura en la parte superior del tejado para que el concreto entrara en los encofrados. También desarrolló una mezcla fluida para que el concreto llegara hasta la parte inferior de la vivienda y a todas las partes del encofrado. Luego, los encofrados se desarmaban y se trasladaban a la siguiente vivienda. Solo construyó unas pocas casas en Nueva Jersey y Gary, Indiana, y algunas de ellas siguen en uso hoy en día.

Arquitectos como Tadao Ando y Frank Lloyd Wright diseñaron viviendas de lujo, de aspecto moderno y elegante, para compradores adinerados. Ando diseñó una vivienda frente al mar en Malibú, California, que se construyó en 2013 y sobrevivió al incendio de Palisades.

Sería estupendo que el concreto pudiera considerarse «ignífugo», pero es más exacto decir que es «resistente al fuego». Nada es ignífugo porque todo depende del tiempo que algo esté expuesto al calor y de la cantidad de calor de que se trate. Esta relación con el concreto se describirá con más detalle en el próximo artículo de esta serie.

Las viviendas de concreto se pueden diseñar, dirigir y construir para resistir huracanes, tornados, incendios, inundaciones y terremotos. Pueden proteger a los habitantes de los árboles que caen sobre las casas y de los escombros que vuelan. Las viviendas de concreto son resistentes porque pueden sobrevivir a las catástrofes sin necesidad de ser reconstruidas. En artículos sucesivos se abordará lo siguiente:

- Cómo se comportan las viviendas de concreto en caso de incendio.

- Cómo los ingenierios diseñan las viviendas de concreto para resistir las catástrofes naturales en aumento.

- Diferentes métodos de construcción de viviendas de concreto y sus costes asociados.

- La resistencia en comparación con el dióxido de carbono creado en el proceso de construcción.

- Información sobre el proceso de desarrollo y modificación de los códigos de la edificación.

- Cuál es el punto de vista de las compañías de seguro acerca de las viviendas de concreto.

El camino que queda por recorrer para reconstruir Los Ángeles y hacer frente a una cantidad monumental de escombros tóxicos será largo y estresante. Esperemos que sus decisiones sean por el bien de todos.