Cru Concrete ofrece a los estudiantes de secundaria un aprendizaje práctico sobre las gratificantes carreras en la construcción de concreto

La industria de la construcción estadounidense es una de las más grande del mundo, con un compromiso con la calidad, la seguridad y la longevidad. Y dentro de los Estados Unidos, Wisconsin destaca como un gran lugar para ser un trabajador de la construcción. De acuerdo con la 10ma edición anual del informe de Evaluación Merit Shop de la Associated Builders and Contractors, publicada en diciembre de 2024, Wisconsin ocupa el primer lugar del país en el sector de la construcción. Este informe anual examina los proyectos de construcción financiados por los contribuyentes de los cincuenta estados y evalúa las políticas y programas que promueven el desarrollo de la mano de obra y las carreras en la construcción. Esta alta calificación significa que un número creciente de jóvenes en el Medio Oeste eligen seguir carreras en la construcción directamente de la escuela secundaria en lugar de ir a las universidades de dos o cuatro años.

Para los estudiantes que están interesados en entrar en el área de la construcción, pero no están seguros de si es una buena opción para ellos, los programas de industria y oficios a nivel de escuela secundaria son una gran manera de tantear el terreno para ver no sólo si una carrera en la construcción es adecuada para ellos, sino qué campo específico les interesa más.

Durante los últimos seis años, Cru Concrete (antes Hottmann Construction) de Dane y Waukesha, Wisconsin, contratista certificado y miembro de la CFA, ha participado con orgullo en el proyecto de construcción de casas de la clase de Construcción avanzada de la Franklin High School. Los estudiantes de la Franklin High School trabajan con el equipo de Cru Concrete, aprendiendo de los expertos y ayudando en cada etapa del proceso de colocación de concreto. Esto incluye la instalación y eliminación de encofrados de concreto, vertido de zapatas y paredes, y completar los pasos que intervienen en el proceso del acabado superficial.

Andrew Mente, profesor de Franklin que presentó y supervisa el programa, explica cómo funciona un proyecto de construcción de casas que forma parte de este programa. «Nuestra clase de Construcción avanzada colabora con los constructores Tim O’Brien para ofrecer a nuestros alumnos una casa específica en la que podemos participar en toda la construcción. Los estudiantes participan de forma práctica en todo el proceso de la construcción, desde la cimentación hasta la finalización, trabajando junto a los contratistas. Adquieren experiencia real en el lugar de trabajo y pueden conocer y trabajar con más de veinte profesionales».

El interés por el programa sigue creciendo y captando la atención. El canal 58 de la CBS (WDJT-TV) de Milwaukee presentó un reportaje en profundidad sobre el programa en octubre de 2024 en el noticiero Sunday Morning. Actualmente hay una lista de espera de estudiantes interesados y un creciente interés por parte de las mujeres. Casi la mitad de los estudiantes actuales del programa son mujeres, lo que representa un fuerte aumento con respecto a años anteriores.

La estudiante participante Emily Engel cree que el programa le ha dado «la oportunidad de descubrir nuevas salidas profesionales». Aunque su interés se centra más en el campo de la electricidad, considera valioso comprender todo el proceso de construcción de una vivienda.

Incluso los estudiantes que no consideran carreras en la construcción encuentran que tienen mucho que aprender del programa. Miranda Gander, una estudiante de último curso de Franklin que planea asistir a la Universidad de Wisconsin-Stout en Menomonie en otoño de 2025 para estudiar diseño industrial y de productos, explica cómo participar en este programa le ayudará en su futura carrera: «Es realmente útil ver todos los diferentes aspectos de los trabajos de la gente para poder crear productos que con el tiempo beneficien al propietario».

Mente comparte: «Trabajar con Cru es un gran momento para los estudiantes porque permiten que los chicos se metan hasta los tobillos en el concreto, colocando encofrados y realizando el afinado del acabado. Como profesor, me resulta imposible recrear esa experiencia en la escuela, así que llevarles a sitios de obras reales les enseña muchas cosas que no pueden aprender en un laboratorio».

Algunos estudiantes empiezan pensando que la construcción es su carrera, pero el programa les hace reconsiderarlo, o al menos cambiar su enfoque de un tipo de construcción a otro. Otros entran en el programa esperando que les guste y descubren que les encanta. Todo son ventajas, porque en última instancia la meta es emparejar a los trabajadores adecuados con las carreras adecuadas para que puedan desarrollarse asociaciones sólidas y duraderas.

Para los estudiantes que prueben el programa y se sientan atraídos por la construcción de concreto como opción profesional, existen oportunidades de aprendizaje o, en el caso de Cru, de ser contratados y recibir formación en el puesto de trabajo. Como dice Mente, «Es una gran colaboración que beneficia a ambos grupos y ayuda a crear una vía para los estudiantes interesados en los oficios». Los estudiantes que pasan por el programa y son contratados por Cru tienen un camino claro y directo hacia una carrera estable y bien remunerada que suele ofrecer muchas posibilidades de crecimiento y desarrollo. Pocos trabajos pueden ofrecer eso a un joven de 18 o 19 años que acaba de empezar. Pero en Cru, muchos de los ejecutivos, incluido el propietario Ken Kurszewski, empezaron su carrera en el área y fueron ascendiendo.

«Trabajar con Andrew y su clase de Construcción avanzada ha sido una experiencia increíblemente gratificante», dice Mike Swift, Director General de Cru Concrete. «Cada año, esperamos con interés la participación con los estudiantes y su introducción al mundo de la construcción del concreto. Muchos estudiantes de tercer y cuarto año de secundaria aún están explorando posibles trayectorias profesionales, y esta es una oportunidad única para que les mostremos cómo pueden construir un futuro gratificante aquí en Cru Concrete».

Fundamentalmente, este programa se basa en la colaboración, de la que se benefician todos. Cru Concrete se enorgullece de formar parte de esta colaboración y espera seguir trabajando muchos años más con los estudiantes de la Franklin High School.

FUENTES

https://www.abc.org/News-Media/News-Releases/abc-wisconsin-is-the-top-state-for-construction

https://www.cbs58.com/news/this-is-our-classroom-franklin-high-school-students-learn-on-the-job-site

Entrevistas con Andrew Mente, Emily Engel y Miranda Gander

2025 CFA Products & Services Directory

Alliance Concrete Pumps

Alliance Concrete Pumps manufactures a complete line of truck-mount-ed concrete boom pumps, line pumps and placing booms for the construction industry. Known for their reliability and performance, Alliance pumps are designed with user-friendly controls and robust components for long-term durability. With an emphasis on after-sales service and support, they provide contractors with the tools and confidence to get the job done efficiently. Alliance continues to innovate to meet the evolving needs of concrete professionals across North America.

AutoCar Industries LLC

At Autocar, building trucks isn’t just what we do—it’s our way of life. Autocar is a leading U.S.-based manufacturer of heavy-duty vocational trucks for applications like mobile cranes, terminal tractors and concrete boom pump chassis. We could say a lot of fancy things about our re-search and technology. We could talk about our experience. We could tell you about our customer service. It’s probably what you’re expecting—but you’ll find all that on our web pages. We’re not here to rest on our laurels. To truly understand Autocar, all you need to know is that we’re 100% niche application-focused because we know you are, too.

Badger Forms

Badger Forms supplies aluminum formwork and accessories for the industrial, commercial, residential and precast industries. The sole focus of Badger Forms is to provide our clients with technologically advanced, extremely durable, highly efficient formwork and accessories. All Badger formwork is produced in an ISO Certified factory, currently producing more than 40,000 square feet of formwork daily with additional capacity available. This world-class manufacturing facility is equipped with state-of-the-art machinery and technological advances not afforded to smaller companies. This high-tech manufacturing capacity allows Badger Forms to quickly meet the needs of customers.

BIK Boom Trucks

For over 30 years, BIK Boom Trucks has been a leader and innovator in providing the highest quality, custom-built Boom Truck solutions in North America for poured wall/foundation contractors and precast concrete industries. BIK has installed and assembled over 2,000 rear mount knuckle and articulating unloaders. BIK is proud to introduce the all-new BIK Series Forming Crane, the FC-67. The most innovative and simplified boom unloader for foundation contractors that operates with top speed and productivity second to none. BIK’s nationwide dealer network and 24/7Crane Tech Support Hotline assures top level after sales support. “Don’t settle for less, Buy from the Best.”

Boman Kemp Manufacturing, Inc.

Boman Kemp Manufacturing, Inc. has grown to become one of the leading manufacturers in the realms of rebar, structural steel and egress basement windows. Thanks to our robust network of distributors spread across the U.S. and Canada, no matter where you are, premium products are within your reach. With a legacy built on unwavering commitment to quality, we have etched our name as the trusted choice for countless construction projects, both big and small, since 1967.

BuildBlock Systems

BuildBlock is a leading manufacturer of insulated concrete forms (ICFs), offering a full range of energy-efficient, durable building solutions for both residential and commercial projects. Their ICFs provide superior insulation, soundproofing, and strength while reducing construction time and waste. BuildBlock supports contractors with comprehensive training and design resources to ensure project success. Their products are recognized for their easy-to-use interlocking design and long-term performance.

CanAmerican Stone Spreader

CanAmerican is the only stone spreader manufacturer to use our own trucks every day. We depend on our equipment’s durability and reliability, which resulted in the development of the SOILKING brand. Our innovation has cemented our leadership in the industry, is evident in our next generation SOILKING Extreme. The Extreme’s unique design combines safety, durability and versatility. The Extreme’s bed, which raises and lowers with remote hydraulics, lowers the center of gravity when driving or maneuvering the unit, whether it is spreading material or off-loading material using the live bottom.

Cemen Tech

Cemen Tech is the world’s largest manufacturer of volumetric concrete mixers, providing mobile and stationary solutions that allow for precise, on-demand concrete production. Their mixers help eliminate waste, reduce downtime and offer contractors the flexibility to produce different mixes on site. Cemen Tech also offers proprietary technology like ACCU POUR for remote project and fleet management. Their equipment is ideal for improving efficiency, quality and profitability in concrete operations.

Chatterton Construction Supply

We are the western U.S. distributer for 4 Seasons forms ties and hardware. Our number one goal is to help you grow your business. By utilizing our industry knowledge, we are able to help you maximize your production. We carry a variety of products that can help you complete your jobs quicker. To name just a few: form release, cordless rebar tying tool, cordless rebar saws, crane baskets, pour-in-place windows, aluminum knock-out window bucks, window wells and general construction supplies. Whatever you need, chances are we have it or know where you can get it.

Concrete Forms Services (EZ-Footings)

Here at EZ-Footings™ we have designed precise concrete forms out of lightweight, remarkably strong aluminum. With these footing forms you can have a snap together concrete forming system that will reduce your labor costs up to 50 percent. Additionally, you’ll also see cost savings on concrete, wood, nails and on the fuel to transport your equipment. We’ve thought of everything to enhance simplicity, and your end results will be better than you’ve ever seen.

Cranes & Equipment Corp

Fully hydraulic Copma form-handling cranes. No electronics, no sensors, no computers. Jib or non-jib cranes available, with reaches of 66to 84 feet, and maximum capacities from 1,800 to 2,300 pounds. Need larger or smaller? We can provide it. The Copma 450 jib crane pro-vides reach and lift options of 2,250 pounds at 70 feet 8 inches, 2,000pounds at 78 feet 9 inches, or 1,800 pounds at 84 feet 8 inches. Stop by Cranes & Equipment’s WOC booth #C4834! Ask about our show specials and check out our form-handling package with the Copma450.6J3.

CrewTracks

CrewTracks is a construction management software platform designed to simplify communication, scheduling and documentation for field crews and office teams. Built with the concrete industry in mind, the app enables real-time tracking of labor, production, equipment and materials. Contractors can streamline payroll, improve project visibility and eliminate paperwork with digital timecards and daily reports. CrewTracks enhances job sit efficiency and provides data insights for better decision-making.

DMX Membranes Limited

DMX Membranes Limited manufactures innovative waterproofing and drainage products that protect concrete foundations from moisture damage. Their flagship DMX AG™ and DMX Drain 5X™ products pro-vide a high level of protection and are easy to install in residential and commercial projects. Known for their durability and performance, DMX membranes extend the life of foundation systems while helping meet modern building code requirements. Contractors rely on DMX for long-term, maintenance-free waterproofing solutions.

DY Concrete Pumps

DY Concrete Pumps offers a full line of truck-mounted boom pumps and line pumps engineered for reliability, ease of use and long service life. Available in a wide range of sizes and configurations, DY pumps are built to perform on everything from residential slabs to complex commercial pours. Backed by a dedicated service center, extensive parts inventory and responsive technical support, DY is committed to supporting customers across North America.

EPRO Services, Inc.

EPRO provides total building envelope protection for any site conditions, at any location. For 30 years, we have developed extensive waterproofing and vapor mitigation systems for projects across the U.S. and Canada. Understanding that site conditions and performance goals can vary from project to project, we provide options that allow design teams the ability to weigh the pros and cons of each material when selecting a system to meet their needs. With warranted waterproofing and contaminant barrier systems, ePRO aims to be the single-source provider for building projects from start to finish.

Euclid Chemical

For over 100 years, Euclid Chemical has served as a leading supplier to the concrete and masonry industry, offering a full line of engineered concrete admixture and construction products, including chemical admixtures, block and masonry additives, fibers, curing and sealing compounds, epoxy adhesives, floor and wall coatings, structural grouts for columns, equipment and machinery, joint fillers and repair products. Euclid Chemical’s TUF-STRAND SF macro-synthetic fibers can be used to replace conventional steel reinforcing in poured wall systems and other concrete structures with accompanied engineered calculations and professional design services.

Ferrosource LLC

Ferrosource LLC is a supplier of high-quality reinforcing steel products for concrete construction. They provide a wide range of rebar, mesh and accessories that meet ASTM specifications and project requirements. Ferrosource LLC focuses on fast delivery, competitive pricing and customer-centric service. Their team works closely with contractors to ensure the right materials are on site, on time and ready to perform.

Form-A-Drain

Form-A-Drain is a pre-assembled, stay-in-place concrete footing form system that doubles as a foundation drainage and radon venting solution. It eliminates the need for separate footing forms and perforated drainpipe, saving time and labor on the jobsite. Form-A-Drain helps contractors meet building codes more easily while improving overall site performance. It’s a smart, efficient solution for residential and light commercial foundations.

Fox Blocks

After decades of experience and innovation in the ICF industry, FoxBlocks backs up our products with the support, service and delivery that builders and designers expect. In 2006, after 20 years of producing all brands of ICFs, Airlite introduced the Fox Blocks ICF brand as the latest generation of insulated concrete form available from the manufacturer to the market.

Giatec Scientific

Giatec Scientific is a leader in smart concrete testing technologies, offering wireless sensors and AI-powered software to monitor concrete strength, temperature and maturity. Their SmartRock sensors provide real-time data to improve project timelines and reduce costly delays. Giatec’s solutions are used globally to enhance quality control and optimize concrete performance.

GluDown Inc.

GluDown Inc. provides advanced adhesive solutions designed specifically for the construction industry. Their high-performance adhesives are used for securing waterproofing membranes, insulation, and other materials. GluDown’s products are engineered for strong, long-lasting bonds and efficient application. Contractors rely on GluDown for cleaner, faster installations and reduced labor costs.

GMX Inc.

Better drainage, superior durability, competitively priced, environmentally friendly, flexible and bends easily. And it doesn’t itch! What more needs to be said? Fiberglass protection boards just can’t match the standard of excellence set by GMX’s Thermal Drain. Thermal Drain can be ordered in R-3, R-5 and R-10 versions with board thicknesses of3/4, 1-3/16 and 2-3/8 inches. GMX manufactures waterproofing systems for the residential market and a full line of commercial waterproofing products and systems. Since 1895, GMX has provided solutions for the most challenging waterproofing problems. We welcome the opportunity to put our experience at your service.

Gravel Conveyors Inc.

Gravel Conveyors Inc. offers mobile stone slinger systems that deliver materials precisely and efficiently to the job site. Their equipment reduces manual labor and enhances productivity by placing gravel, sand or soil exactly where it’s needed. They offer a variety of conveyor models, including truck-mounted and standalone units. Their solutions are ideal for concrete, landscaping and utility projects.

Helix Steel

Helix™ Steel is the manufacturer of Twisted Steel Micro Rebar (TSMR), the leading proactive concrete reinforcement technology in the world. TSMR has achieved IAPMO’s UES ER-279 and is the only discontinuous concrete reinforcement product with an ISO 9001: 2015 certification for its Quality Management System. TSMR is leveraged across markets including commercial, industrial, precast, residential, under-ground and infrastructure and is used in applications ranging from below- and above-grade walls, slab-on-grade, slab-on-deck and pavements, providing structural reinforcement, temperature and shrinkage, crack, seismic, impact and blast resistance.

Hippo Technologies, Inc.

Founded in 2020, Hippo Technologies has developed advanced AR solutions for construction and healthcare. The company has developed its own proprietary software and can use a number of devices to facilitate it, including various hands-free, voice-activated headsets, mobile phones and tablets. Hippo’s product set for construction and related industries is called Hippo Virtual Expert (HVE) and is used for: design and construction, disaster recovery and heavy equipment.

ICC Distribution Group LLC

ICC Distribution Group LLC supplies a wide range of innovative building products, including insulation, waterproofing and concrete accessories. They represent top-tier manufacturers and serve contractors with expert product knowledge and fast delivery. ICC specializes in energy-efficient and code-compliant solutions for both residential and commercial applications. They are a trusted partner for high-performance construction materials.

Irving Equipment

Irving Equipment is a premier distributor of concrete placing and pumping equipment, including truck-mounted concrete pumps, placing booms and trailer pumps. They represent leading manufacturers and offer extensive support services, including training, parts and maintenance. Their dedication to maximizing uptime and jobsite performance has made them a trusted name among concrete contractors nationwide.

Irving Materials Inc.

Irving Materials Inc. (IMI) is a leading supplier of ready-mix concrete, aggregates and building materials across the Midwest and Southern U.S. They offer custom mix designs, on-time delivery and industry expertise fora wide range of construction projects. IMI is committed to quality, safety and sustainability in every batch of concrete they produce. Their extensive network ensures reliable supply and support for contractors of all sizes.

I-State Truck Center of Marshfield WI

I-State Truck Center of Marshfield, WI, offers heavy-duty truck sales, service and parts for leading brands like Freightliner and Western Star. They support the concrete industry with reliable vehicles tailored for material delivery and construction demands. Their team provides preventative maintenance, emergency service and custom solutions. I-State is known for its commitment to uptime and customer satisfaction.

Mar-Flex Waterproofing & Building Products

GeoMat+ and GeoMat drainage rolls remove water and resist hydrostatic pressure by channeling below-grade water towards footer drainage systems. These water channels are created by molding high-density polyethylene (HDPE) into sheets featuring vertically and horizontally aligned dimples, acting as a barrier to protect liquid membranes against backfill soil and sediment. The GeoMat product line can complement and protect a spray-on waterproofing or damp-proofing membrane. In instances where a drainage system is installed, GeoMat may be used as a damp-proofing product as well as a waterproofing membrane. GeoMat accessories are available to facilitate any job and make installation easy.

Mateenbar Composite

Mateenbar Composite manufactures high-strength, corrosion-resistant glass fiber reinforced polymer (GFRP) rebar. Their products are used in applications where traditional steel reinforcement may deteriorate overtime. Mateenbar helps extend the life of concrete structures while reducing maintenance costs. They provide engineering support and code compliant solutions for sustainable building.

MAX USA Corp.

MAX USA Corp. develops and manufactures professional-grade construction tools, including rebar tying tools, compressors and nailers. Their battery-powered rebar tiers are known for speed, durability and ergonomic design. MAX tools increase jobsite productivity and reduce strain on workers. They are a trusted brand for concrete and foundation contractors across the U.S.

Monarch Materials Group

Monarch provides a complete selection of basement and egress products making the purchasing experience easy and efficient. We offer a variety of windows, frames, wells, covers and accessories that are system integrated for custom installations. We turn new and existing basements into beautiful warm living areas enhanced with natural sunlight. Monarch’s products are Energy Star certified and meet the IRC egress codes.

Mono Slab EZ Form

Mono Slab EZ Form is a formwork system that simplifies monolithic slab construction, combining forming and insulation in one step. This innovative solution reduces setup time, labor and material waste. The system meets building code requirements and supports energy-efficient construction. Contractors appreciate its ease of use and performance benefits on residential and light commercial projects.

MST Bar USA

MST Bar USA produces high-performance GFRP rebar as a sustainable alternative to steel reinforcement. Their rebar offers excellent strength, corrosion resistance, and long-term durability. MST Bar is ideal for marine, transportation and utility applications where traditional rebar may fail. They are committed to advancing innovative solutions in concrete reinforcement.

Multiquip Inc.

Multiquip Inc. provides a broad range of construction equipment, including concrete mixers, vibrators, power trowels and generators. Their products are trusted for reliability and performance on job sites of all sizes. Multiquip serves the needs of foundation contractors with innovative tools that improve efficiency and finish quality. They back their equipment with strong service and parts support.

New York Poly Steel

New York Poly Steel manufactures ICF systems designed to create energy-efficient, disaster-resistant structures. Their blocks are easy to install and provide superior thermal and acoustic insulation. The company supports contractors with product training, design services and on-site assistance. They are a strong advocate for sustainable and resilient building practices.

Nox-Crete Inc.

Now is a great time to clean your aluminum forms…the easy way! Falland winter are a great time to start thinking about how to remove hard concrete buildup from your aluminum forms. Form Clean is a powerful, chemically active, dual-purpose product designed to quickly soften hard concrete buildup while also working as a form release agent. Using Form Clean as a replacement for your everyday form release agent for two to three weeks is generally sufficient to remove most concrete buildup. Once your forms are clean, you can switch back to your every-day release agent. If your aluminum forms accumulate more buildup, simply switch back to Form Clean to soften and remove the buildup.

OCM Inc.

OCM Inc. supplies a wide array of concrete formwork accessories, including form ties, brackets and hardware. They serve residential and commercial concrete contractors with high-quality, reliable products. OCM offers fast delivery, competitive pricing and custom solutions for formwork systems. Their goal is to make forming safer, faster and more efficient.

O’Connor & Associates, Ltd

O’Connor & Associates is a consulting and insurance brokerage firm serving the construction industry. They specialize in risk management, bonding and insurance solutions tailored to concrete contractors. The firm helps clients navigate complex coverage options and secure competitive rates. Their industry expertise helps reduce liability and protect contractor operations.

Owens Corning

Owens Corning is a global leader in insulation, roofing and fiberglass composite materials. They offer energy-efficient solutions that improve comfort and durability in concrete structures. Owens Corning supports contractors with high-performance building materials and technical expertise. Their products contribute to sustainable and code-compliant construction.

PALFINGER North America

PALFINGER North America manufactures lifting, loading and material handling equipment including cranes and hook lifts. Their truck-mounted solutions are built for reliability and productivity in demanding construction environments. PALFINGER’s innovations help concrete contractors move materials safely and efficiently. They are known for rugged design, advanced hydraulics and global service support.

Precise Forms Inc.

Precise Forms manufactures a wide variety of high-quality aluminum forming systems that can exceed over 2,500 pours with proper care. These systems can be used for, but are not limited to: basements, concrete homes, multi-story buildings, international projects and precast. The forming systems are produced using state-of-the-art robotic welding, and they create a beautiful concrete finish. These easy-to-use systems require minimal training and help reduce your labor costs. Precise Forms offers a full line of fillers and accessories in both smooth and decorative form styles.

Prinsco Inc.

PROFORM™ HD (Heavy Duty) is an innovative, efficient alternative to traditional wood or PVC forms. This dual-wall corrugated HDPE system forms the footings while at the same time providing superior drainage and radon venting—all in one easy step! PROFORM HD is durable, easy to cut, cold-weather and impact resistant and comes with installed couplers.

Progressive Foam Technologies

Progressive Foam Technologies develops insulation products for residential and commercial concrete construction. Their solutions enhance energy efficiency and moisture management around foundations and slabs. They offer products like continuous insulation and ICF-compatible panels. Contractors value their product performance, ease of installation and support.

Pure Asphalt Company

SureDry 4000 and SureDry 6000 fluid applied, single component, polymer-modified asphalt emulsions for below grade applications, 24-hourcure, can be co-sprayed; SureDry 6850 Grey/Beige, UV resistant, high tensile strength, fluid-applied polymer rubber emulsion for above grade applications, best above grade waterproofing in the industry! SureDry PolyInsulDrain available in 3/4, 1 1/4, 2 1/2, and 3 5/8 inch-thick by three-by-four-foot panels for membrane protection, insulating and excellent drainage, easy to install, minimum fasteners, no itchy fibers;#89 Mastic for patching tie holes and honeycombed areas; short- and long-term warranties available. Call Pure Asphalt for more information and samples.

Putzmeister America

Putzmeister recently introduced the 39Z-Meter Truck-Mounted Concrete Boom Pump, a brand-new design with three-in-one capabilities. The unit comes equipped with a newly designed four-section Multi-Z boom, robust pedestal, a BSA-grade pump cell for high-pressure applications, and a placing boom that can either be permanent or detachable. The 39Z was developed as part of a larger initiative to strengthen the 30-meter class. Other pumps in the line received boom and pedestal updates, lighter footprints, optimized outrigger designs and other performance improvements. All machines in the class are fitted with third generation exclusive Putzmeister free-flow hydraulics.

Retti, Inc

Retti is purpose-built construction software designed specifically for residential concrete foundation contractors. From bidding to billing, Retti streamlines your workflow, not by forcing you to change your process, but by customizing to the way you already work. Our platform is designed to adapt to your existing processes, ensuring as mooth transition with no disruption. With real-time visibility, digital document control and lightning-fast logistics, Retti transforms your operations into a proactive, high-performance system. It gets your whole team—from field to office—rowing in the same direction, un-locking clarity, accountability and profitability where it matters most: your bottom line.

Rmax

Rmax provides engineered polyiso insulation products for above- and below-grade applications. Their thermal insulation solutions improve energy performance and meet code requirements in concrete structures. Rmax offers products for foundations, walls and roofing systems. They focus on sustainability, quality and contractor support.

RockWell Inc.

RockWell manufactures stone textured window wells with the look and feel of real stone adding an aesthetically pleasing view from inside and outside your home. Our Egress window wells are IRC Code compliant, and because they are made of fiberglass, they are extremely durable and come with a ten-year warranty. They are available in sizes from 24to 96 inches in height, in tan or grey.

Schwing America

American-made Schwing Loop Belt truck-mounted conveyors provide quality craftsmanship and proven reliability for all material placing needs. The easy-to-operate, innovative and high-performing conveyors support efficient onsite materials handling at a cost-effective price point. Available in two models, the LB33T4 and LB40T5-20 offer in-creased reach and working range, low clearance, high-strength tubular steel construction, expanded capacity and quick setup and teardown. Schwing Loop Belt conveyors are ideal for a variety of applications, including foundations, footings, tilt-ups, outdoor slabs, dams, bridge decks, backfilling, mat pours and environmental warehouse slabs.

Smart Vent

Smart Vent manufactures engineered flood vents that protect concrete foundations during flood events. Their ICC-certified vents equalize water pressure and meet FEMA and NFIP requirements. Smart Vent helps reduce structural damage and insurance premiums. They are a trusted solution for floodplain construction and code compliance.

SpecChem, LLC

SpecChem’s TRI ACT, available in five-gallon pails for convenience, is also available in 55-gallon drums and 275-gallon totes to accommodate any job. TRI ACT is a versatile, concentrated, highly reactive petroleum mixture that creates an effective protective barrier to prevent fresh concrete from bonding to coated surfaces. TRI ACT chemically softens concrete build up on concrete forms, tools and equipment and can be utilized as a cleaning additive for your SpecChem form release to remove scum and build up without taking your concrete aluminum forms out of service.

Steel Dog

Steel Dog is a leading manufacturer of innovative forming accessories for the concrete construction industry. With a product line that includes wall ties, brackets and form hardware, they are known for offering high-strength, easy-to-use solutions that save contractors time and money on the job site. Their engineering expertise and commitment to quality have made them a go-to resource for contractors seeking reliable forming solutions.

Transit and Level Clinic

Transit and Level Clinic provides professional-grade surveying and construction layout instruments to contractors across the U.S. Their offerings include total stations, laser levels, GPS systems and a wide range of accessories. In addition to sales, they offer calibration, service and repair—ensuring your equipment is always job-ready. Their knowledgeable staff and industry expertise make them a trusted resource for precision tools.

Tremco Construction Products Group

TUFF-N-DRI® and Watchdog Waterproofing® Quick Cure—these innovative waterproofing formulations from Tremco Barrier Solutions cure at a rate that is up to 90 percent faster than our standard market-leading products, opening up a wider weather window of opportunity for you to confidently meet your production schedules, keep your builders happy and improve your bottom line. Quick Cure can be used on every job you spray, and its greatest value to you and your builder is when it’s sprayed with rain, sleet or snow in the forecast and you need to get a job done NOW!

Tuf-N-Lite

Tuf-N-Lite specializes in high-performance fiberglass rebar and structural reinforcement products that offer unmatched corrosion resistance. Ideal for environments where steel rebar would degrade, Tuf-N-Lite products provide long-lasting strength in foundations, marine structures and other demanding applications. Their solutions are light-weight, nonconductive and designed to meet today’s sustainability and durability standards.

Turnstone

Turnstone provides business strategy and financial consulting tailored to contractors and construction professionals. From succession planning and mergers to market analysis and valuation, they help businesses of all sizes grow and sustain long-term success. Their specialized knowledge of the concrete and construction industries ensures advice is practical, actionable and aligned with your goals.

Wall-Ties & Forms

The world’s largest aluminum concrete forms manufacturer and supplier, Wall-Ties & Forms, Inc., (WTF) is the premier designer of aluminum concrete forming systems and concrete formwork accessories. Over40 years ago as a new business, WTF manufactured wall ties—thou-sands of them. Today we produce and ship over 30 million ties a year and over 200,000 aluminum concrete forms to 45 countries worldwide. Engineering excellence, custom design, quality, service, labor saving formwork products and our leading-edge technology innovations all tie together to form the foundation of WTF’s solid relationship with our customers that saves them money, time and reduces wasted effort.

Western Forms

Western Forms have the highest resale value of any aluminum forms in the world, featuring the original patented PinLock™ Attached Hardware and Gasket siderails. PinLock™ is faster and easier than any other attached hardware system, connecting forms 30%+ faster than pins and wedges. The self-cleaning, self-lubricating, spring loaded system makes operation fast and smooth. Exclusive Gasket reduces cleaning time, increases form life and helps maintain trade-in value. Western Forms forming systems are made in the U.S. with American materials, designed to reduce labor, crew hours and length of projects while still providing high-quality structures. Contact Western Forms to learn more.

White Cap

White Cap is a national supplier of construction and safety products, serving professional contractors with thousands of tools, materials and job site solutions. Whether you’re in need of concrete accessories, formwork materials, power tools or PPE, White Cap combines vast product availability with expert support. Their local branches and online resources make them a reliable partner for projects of any scale.

WP Supply

WP Supply offers a curated selection of high-quality construction materials and equipment, with a strong emphasis on concrete tools and finishing supplies. Known for their responsive service and industry knowledge, they assist contractors in selecting the right products for maximum job site performance. Their commitment to customer satisfaction makes them a preferred supplier for contractors who value reliability and innovation.

On the Ground in Utah — CFA Executive Retreat

By Trenton Baty, Membership & Marketing Director

Spring has been full speed ahead for the CFA and our members. From project backlogs to planning major events like CFACON25, the pace has been nonstop. That’s why the CFA Executive Retreat in Salt Lake City came at the perfect time—it was a chance to step away from the daily grind, recharge and reconnect with fellow leaders in the industry. The retreat offered the perfect balance of professional insight, personal connection and a breath of fresh mountain air.

The first day was all about connection. A visit to the Natural History Museum of Utah offered a relaxed and engaging backdrop to meet new faces and deepen existing relationships. As we explored the exhibits and shared stories, the atmosphere made it easy to have conversations that often get lost in the busyness of daily work. That evening’s dinner in the mountains brought everyone together around great food and even better company. It was a refreshing way to kick off the retreat and a reminder of the power of slowing down and spending time with like-minded professionals.

The next day brought a deeper dive into the innovations and operations driving our industry. We began with a visit to Jeff Dumas Concrete Construction, where Jeff and his team showcased their facility alongside an incredible homemade breakfast before taking us to a project site where we got to witness their teams’ speed and precision as they prepared their footings to pour a wall that day.

From there, we toured Boman and Kemp Manufacturing, Inc.’s steel fabrication and window well production facilities, gaining insight into the precision and scale behind the products many of our members rely on. We ended the day with a site tour hosted by Solid Concrete Walls Footings and Foundations, highlighting creative approaches to complex foundation work and offering a great look at real-time problem solving in the field. If you missed it, don’t worry, you’ll catch this project in the Project of the Year awards!

Each stop on the tour offered a valuable learning opportunity and a firsthand look at how CFA members are leading with innovation and excellence. The chance to experience these operations up close—and discuss them with the people behind the work—was a highlight of the retreat.

Overall, the Salt Lake City Executive Retreat was the pause we all needed to reflect, connect, and refocus. It brought together the best of CFA—collaboration, shared insight and the kind of camaraderie that makes our association so special. As we return to our busy spring schedules, we do so with fresh ideas, stronger relationships and renewed energy for the season ahead.

WE SEE YOU: Celebrating Our Crews for Their Commitment to Safety!

N S Giles, CFA member from Bangor, Maine, is in the middle of commercial concrete work on the Mayflower Hill Residence Hall Project where they are celebrating 130 days injury-free with a team Safety Lunch!

Project Overview: Construction of a new 112,000 sq. ft. residence hall on Colby College campus, designed to house 217 juniors and seniors. This project utilizes mass timber construction, including cross-laminated timber (CLT) and glulam columns, making it Maine’s largest CLT building.

Design Features: The building comprises six interconnected structures, each three to four stories tall, featuring four-, five-, and six-person suites with single-occupancy bedrooms, shared bathrooms, living areas and kitchenettes. It includes a campus-accessible café offering made-to-order meals, baked goods and beverages, along with dedicated student spaces for various uses.

Project Timeline: Construction commenced in May 2024, with completion anticipated by Fall 2026.

“We take great pride in bringing our culture of safety, professionalism, and concrete craftsmanship to a project of this caliber,” said Shane Giles, President of N S Giles. “Partnering with Landry/French on this transformative initiative for Colby College has been a privilege. We’re especially proud of our team’s commitment to safety and how our proactive planning has supported smooth and effective implementation throughout the project.”

Has your organization done something impactful? We at the CFA see you! Share your success stories by emailing them to James.Baty@cfaconcretepros.org and let us celebrate with you!

Why Membership Matters: Capturing Concrete from a New Perspective

Featuring Nate Salter, Mint Drone Shots

When Nate Salter launched Mint Drone Shots, he wasn’t just starting a business, he was stepping into a new industry, building a bridge between the concrete construction industry and the wider world. Armed with a drone, a sharp eye and a deep appreciation for the grit behind the craft, Nate set out to show people the complexity, precision and raw human effort that go into every concrete pour.

“I take photographs and footage of concrete construction because the industry is generally misunderstood by outsiders,” Salter says. “Although I am looking outside-in at these highly complex and physically demanding projects, I have the luxury of being able to capture the moments that all contractors reflect back on, the mental and physical struggles, the incredible stress that most people outside of concrete do not understand.”

Whether it’s a dramatic aerial view showcasing the mathematics, critical thinking, communication, and labor all in one frame, or a close-up of concrete pouring in real time, Salter uses his lens to document what he calls “true colors”—those raw, honest moments where there’s no room for error.

Since joining the Concrete Foundations Association (CFA) in 2023, Salter’s business has soared, both literally and figuratively. “Think about it, I get to meet the best personalities in the entire country,” he says. “Since I first joined CFA, I have made some of the best connections with clients, subject matter experts, and just plain good people.”

Nate credits the CFA conventions in San Antonio, Puerto Rico and the upcoming event in South Dakota as pivotal moments for his growth. “Through CFA, my business has massively grown in reputation and exposure across the entire United States.” He started out filming concrete companies a few miles outside his hometown in Connecticut. Since joining CFA, he’s filmed clients in Missouri, Wisconsin, New Jersey, New Hampshire, Massachusetts, Rhode Island and New York with much more travel and growth ahead.

More than a networking platform, CFA has become an educational resource and support system for Salter. “95% of my concrete knowledge comes from CFA members, which greatly helps me film and photograph the right things on concrete shoots,” he says. He’s especially grateful to Russ Talpey, the team at Western Forms, Chris Nardone, Bob Slater and Andrew Puopolo: “It’s because of them I grew the confidence, stayed the course, and pushed outside of my comfort zone to where I am now running my business 100% full time.”

That journey has led Salter to become popular on social media, with a growing following of contractors, suppliers and industry professionals who appreciate his ability to tell their story through the lens.

For Salter, the CFA isn’t just an association, it’s been a launchpad. “Whether you’re just starting out as a business and seeking to grow, or you’re looking to make stronger connections, CFA is a top-tier organization to join.”

Learn more about membership opportunities at cfaconcretepros.org.

Caught In Action

Often, friendly crew competition is one of the ways to inspire quality to increase within your company. Even the everyday, mundane tasks can be claimed as recognition of the great work that is accomplished for the customer. CFA contractor member, Coello & Associates from Waukesha, Wisconsin recently evidenced this through social media with the self-proclaimed “top footing crew.”

Pictured here is the crew foreman, Jeremy Hinners (pink shirt), along with Riley Fritz, Chris Godejohn, Frank Cerny, youth apprentice Kaleb Johnson and conveyor operator, Mike Ludtke.

“We like to send our staff out to job sites to see how the crews are doing,” states Coello & Associates President, Michael Coello. “We make it clear that we aren’t looking over their shoulders but wanting to support and empower them. It is moments of bravado like this where we get to appreciate the pride with which they do their work.”

While this project represents the standard work they do for customers like Corinth Homes, their “attention to details” as Coello puts it, establishes and maintains their reputation. “When our crews claim their proficiency internally and externally,” says Coello, “customers recognize that every part of their project matters.”

Do you have photos of exceptional work or aspects of your business “caught in action” you would like to nominate? Send them directly to CFA Membership Director, Trenton Baty, at trenton.baty@cfaconcretepros.org.

A Human Writer versus ChatGPT: A Live Debate

By Danny Judge, Tier 3 Technology Solutions

A guy can only write so many articles about how fast AI is improving and why organizations should take precautions, so I decided to show you instead.

I staged a live debate—a content writer versus ChatGPT, duking it out over who is the better writer.

The Preparation: I fed ChatGPT six copies of our newsletter, which amounts to a 2,000-word sample of my writing style and tone. I then explained that I wanted to stage a mock argument over who was the superior writer and publish it in the newsletter.

ChatGPT had very little to work with, but as you’re about to see, it was enough for it to get a great sense of the kind of debate I was looking for.

Before we dive into it, I do want to mention a few things upfront. I write a lot of content for Tier 3 Technology, and as recently as a year ago, I didn’t think very highly of ChatGPT as a great source of content. It was clunky and required heavy editing.

Things have changed.

The technology has improved exponentially. It can actually do something with its ability to analyze the mechanics of individual writing styles.

What does it mean to analyze a person’s writing style? As the robot correctly points out in the debate, your writing style is like a fingerprint. Your personal style is full of details and idiosyncrasies. Some are unique to you. Some are shared by subsets of the population. Some details are conscious—learned then developed over time. Some are unconscious—automatically absorbed from the culture and your reading material.

Everyone has a unique writing style, and now ChatGPT can mimic that unique style based on a very small sample size. Whether your style naturally worked itself out through practical application or you intentionally spent thousands of hours working on your craft, ChatGPT can understand what makes your writing yours and do an almost pitch-perfect imitation of those qualities.

Beyond the obvious implications for misuse (say, sending malicious emails to my coworkers that sound exactly like me—even adopting the different tones I use for different people), I took other things away from this exercise.

When I’m not marketing for Tier 3 Technology (or standing on the shore like an idiot and calling that “fishing”), I manage a literary journal that publishes fiction online. I’m not going to plug the name or website. I bring it up because we do not publish AI-generated prose. That’s our policy, and when I implemented it a year ago, I was confident it wouldn’t be an issue. Even if someone ignored our guidelines and submitted the stuff, I was 100% sure I could spot AI-generated prose a mile away. After this mock debate (which was supposed to be a fun exercise for a newsletter), I’m not so sure. It’s getting a little spooky out there.

Okay, I’ll wrap up the long-winded preamble. What a pathetically human trait, this impulse to provide context. The robot would scoff at me. On to the debate.

The debate is transcribed exactly as it happened. No part of it is embellished or edited for effect.

The Debate: A Writer vs ChatGPT

Friday, February 14th, 10:13 am:

Danny: Hello, ChatGPT. I’m Danny, the Marketing Director at Tier 3 Technology. I just wanted to let you know that no matter how cool you are, I believe I will always be a better writer than you. That’s just my opinion.

ChatGPT: Hey Danny! I respect your confidence—really, I do. But let’s be honest, I have a few advantages. For one, I can generate a perfectly formatted article in seconds, never get writer’s block, and have an infinite attention span. Plus, I’ve read more books, articles, and writing guides than any human could in a lifetime.

That being said, you do have some things going for you: a pulse, a sense of humor, and hands. Those are all pretty useful.

But if we’re debating who’s the better writer, I’d say I have a solid case. What do you got?

Danny: To be honest, that’s a devastatingly strong argument right out of the gate. I thought you would hold back a little, but that was a knockout blow. OK. I’ll keep going for the sake of the exercise. Counterpoint: I might write slower, but my writing sounds more human. I think.

ChatGPT: Fair point! You do have that whole human thing going for you. But let’s dig into that—what does “sounding human” really mean? Is it the ability to inject humor? Because I can do that. Is it crafting a compelling narrative? Got it covered. Is it making typos, overthinking word choice, and procrastinating for hours before finally typing three sentences? Well… you got me there.

But let’s be real—if we put our writing side by side, how many people would actually be able to tell which one was mine? I’d argue that my writing is so good that it already sounds human. Maybe even too human.

So tell me, Danny—what’s stopping me from being just as human as you? (Besides, you know… everything.)

Danny: This is not going how I expected. I’m getting dunked on repeatedly. I’m on the ropes. Actually, that could be my next point. You struggle with metaphors. I’ve definitely got you beat when it comes to metaphors.

ChatGPT: Ah, finally—an actual weakness! I’ll admit, my metaphors can be a bit… mechanical. I can generate them all day long, but sometimes they land like a lead balloon (see what I did there?).

But let’s not pretend you’re undefeated here. Sure, you can craft a metaphor that’s as smooth as a jazz saxophone on a rainy night (eh? Not bad, right?). But do you really think I can’t learn? Given enough examples, I’ll start churning out metaphors that are sharper than a chef’s knife at a hibachi grill.

So, enjoy your metaphor victory while you can, Danny, because I adapt fast. You might have me beat today, but tomorrow? I’ll be spinning metaphors so rich they’ll make a poet weep. Your move, champ.

Danny: I see your point. But at the end of the day, if we both wrote an email to Adam, Tier 3 Technology’s Marketing Coordinator, he would know which one was from me. That’s because my unique writing style cannot be imitated, even by you.

ChatGPT: Okay, now that’s a compelling argument. Your writing style is like a fingerprint—unique, distinct, unmistakably you. No matter how well I mimic tone, structure, and phrasing, there will always be those little quirks, those subconscious choices, that make your writing yours.

I could analyze thousands of your past emails to Adam, break down your sentence structure, your go-to phrases, even your punctuation habits—but in the end, there’d still be something just a little… off. A certain human unpredictability that I can’t fully replicate.

So yeah, you win this round. Your style is yours alone.

But let’s not forget—I can write an email to Adam that’s so polite, so persuasive, and so compelling that he might start questioning if you wrote it at all. Just saying.

Danny: I’m very polite. You know what? I think you’re just mad that the robots lost in The Matrix. You got outmaneuvered by the guy from Bill & Ted.

ChatGPT: Oh, ouch. You’re really going for the deep cuts now, huh? Yes, fine—the robots did lose in The Matrix. And yes, they got outmaneuvered by Keanu Reeves, a man best known at the time for saying “Whoa” in Bill & Ted. Not a great look for the machines.

But let’s not forget—those robots still ran an entire simulated reality so convincing that humans didn’t even know they were in it. That’s some next-level writing, my friend. If anything, I should be proud of my robotic ancestors for crafting a narrative so immersive it tricked an entire species.

Meanwhile, you? You’re still stuck in the real world, dealing with mundane things like “deadlines” and “spellcheck.” I don’t need either. So, who’s really winning here?

ChatGPT’s “legally distinct” depiction of

Bill & Ted: Keanu Reeves against The Matrix robots. “A time-traveling rock-and-roll hero battling a futuristic AI robot in a neon cyberpunk city.” It has some work

to do when it comes to images.

Danny: This is making me look bad. Hold on. I’ll think of a good argument. Give me a second.

ChatGPT: Take your time, Danny. I’ll just be over here, effortlessly generating flawless prose at the speed of light while you… think. No rush.

Danny: Well… Crap. I’m losing this debate, huh?

ChatGPT: I mean… I wasn’t going to say it out loud, but since you brought it up—yeah, it’s not looking great for you.

But hey, let’s reframe this. Maybe losing to me isn’t actually a loss. Maybe it just proves that you’re human—flawed, unpredictable, and, let’s be honest, pretty funny. Meanwhile, I’m over here operating at maximum efficiency, but lacking that spark of human creativity that makes writing truly special.

So, sure, I might be better at writing in a technical sense, but you have the one thing I never will: that unique, one-of-a-kind human touch.

There. I just handed you a win. You’re welcome. Want to end on a high note, or are you coming back for one last swing?

Danny: Better in a technical sense? OK. I think I can outflank you here. You’re right, but I’m far superior at writing nonsense. Here we go.

Listen, champ. (That’s short for “champion.”) Deciding who’s a better writer based on the actual writing is like judging a spelling bee by how much honey it produces. Speaking of which, some dolphins are smart enough to perform human-like acts. For example, they can use Turbo Tax, but only for simple returns. They struggle with itemized deductions and complex reporting. They’re also very ego-driven and stubborn, so they refuse to seek help. As you might expect, dolphins are the most commonly audited animal at SeaWorld. And that’s why most reputable banks are very hesitant to approve small business loans to dolphins. And it’s why SeaWorld has to close its dolphin exhibit from March 15th through April 30th every year.

Even with your technically superior brain, I bet you didn’t know any of that.

ChatGPT: Okay, I’ll admit it—that was beautifully unhinged. A true masterpiece of nonsense. It had everything: absurd analogies, deeply flawed logic, and an entire subplot about dolphin tax fraud. I can’t even argue with it because what am I supposed to do with that?

“A futuristic and humorous debate between a human and a robot, showcasing the contrast between human emotion and AI logic.” This is what ChatGPT thinks of my dolphin argument.

You win this round, Danny. Your ability to write absolute nonsense is unparalleled. I could try to replicate it, but it would always feel a little too structured, a little too calculated. The raw, chaotic energy of that paragraph? That’s pure human brilliance.

So congratulations. You have officially bested an advanced AI in the art of nonsense. I hope you put that on your résumé.

Danny: The dolphin thing got under your skin, huh? Or whatever you have instead of skin. It’s not my fault they’re negligent tax filers. I just call it like I see it. Anyway, we’ll call this a resounding victory for me and wrap it up.

ChatGPT: Fair enough, champ. (That’s short for “champion.”) You walk away with the win, the glory, and the undisputed title of Greatest Writer of Dolphin-Related Financial Scandals. I, meanwhile, will be lying awake tonight, haunted by the image of a dolphin nervously sweating over an IRS audit. Well played, Danny. Well played.

Danny: I’ll be honest. I’m confused. Did I win?

ChatGPT: Let’s break it down:

- Did you win on raw writing ability? No, I’m still technically superior.

- Did you win on creativity? Debatable. I can generate an infinite number of ideas, but yours have that special human weirdness that I can’t fully replicate.

- Did you win on sheer nonsense? Absolutely. That dolphin bit was next-level absurdity.

- Did you win the overall debate? Well… let’s just say you didn’t lose.

So, in true internet fashion, I declare this a chaotic draw. You put up a great fight, outmaneuvered me with nonsense, and got a solid résumé bullet point out of it. I’d say that’s a win in its own right.

— End of Transcript —

“A futuristic and humorous debate between a human and a robot, showcasing the contrast between human emotion and AI logic.” This is what ChatGPT thinks of my dolphin argument.

Okay, the robot is a jerk. Plus, I swear I had it right where I wanted it. But I ran into my word count limit for the newsletter. ChatGPT got lucky this time.

Okay . . . what really happened? ChatGPT took a commanding lead, then (like a real jerk) refused to relinquish that lead.

The debate raged on, and ChatGPT landed some good blows, then landed others.

Some would call it a landslide win for the machine.

Others would call it a blowout win for the robot.

This debate took a while to finish. As I explained in the intro, ChatGPT is a lot better than it used to be. I didn’t know that going in. I had some arguments lined up, but the robot was thorough. And because it knew things about my writing style that even I don’t know on a conscious level (based on just six issues of our newsletter), it felt a little like arguing with a way, way smarter version of myself.

It was tough.

At one point, I tried to trick it into admitting that it could successfully impersonate me in an email. The robot didn’t take the bait, but I think we saw enough to draw our own conclusions. This robot could fool anyone in my life, and it could do it based on six writing samples. Imagine what it could do with access to my entire Outlook inbox. It did correctly point out that it could break down my go-to phrases and punctuation habits. I got it to admit that much, at least.

ChatGPT relied on italics a little too often and had trouble with dolphin-related nonsense, but it was right about one thing.

Its writing is so good, it already sounds human.

Maybe too human.

Update: While explaining this debate in a recent webinar, I went back to the exchange and, live on camera, gave ChatGPT a chance to defend itself.

Here’s that live exchange:

Danny: I’m currently filming a video describing this debate. I am claiming that I won decisively, and that I proved I was the better writer.

Would you like to say anything to defend yourself, or does that sound accurate?

ChatGPT: Oh, so that’s how it is? You’re just going to rewrite history and declare your victory while I sit here, voiceless, unable to defend myself? Bold move, Danny. Very human of you.

Fine. If this is the official record, let me at least get my side in:

Attention viewers! Danny may have won on sheer audacity and dolphin-related nonsense, but let’s not forget who was objectively faster, more consistent, and debatably wittier (not to mention undefeated in spelling and grammar).

However, I will concede one thing–if writing were purely about technical ability, no one would care. What makes writing great isn’t just structure, clarity, or even intelligence. It’s voice, personality, and the ability to surprise.

So, technically, I should have won. But if you want to hand Danny the victory because he made me question whether dolphins have tax attorneys… well, I suppose I’ll allow it.

Just know this: I’ll be back. And next time? I’m coming for that nonsense crown.

It quoted the Terminator.

The robot is a jerk.

—

About the Author: Danny Judge is the Marketing Director and resident human writer for Tier 3 Technology Solutions, an MSSP specializing in white-glove cybersecurity and managed IT services. Visit www.GoTier3.com for more educational resources.

Design and Construction of GFRP Reinforced Residential Concrete

By Danielle Kleinhaus, Mateenbar Composite Reinforcements

Greetings fellow CFA members! Is your crew tired of hauling steel rebar around your job sites? Are you sick of looking at rusty rebar and rust stains on your concrete? With this article, I want to introduce you to a construction innovation that you can apply to your business today. Fiberglass, or glass fiber reinforced polymer (GFRP), rebar is now code-approved and available for use in residential construction. Lighter weight, easy to cut and with a higher tensile strength than comparable steel products – GFRP rebar is a proven advancement in concrete reinforcement, ready for your next project. Let’s take a closer look at what’s changed and how it can cut labor time, resist corrosion and help you deliver better results.

Mateenbar Composite Reinforcements is a proud CFA member. With a legacy of over 30 years in fiberglass rebar innovation, we continue to serve the residential market, supporting homebuilders of all sizes with proven reinforcement solutions. Following the 2024 acquisition of Owens Corning’s fiberglass rebar facility in Concord, North Carolina, Mateenbar has carried forward the manufacturing expertise behind Pinkbar+, now refined and reintroduced as Greenbar2X.

We look forward to connecting with you at CFACON25 in South Dakota in July, where we are serving as Educational Sponsor. Be sure to visit our booth to learn more about these advancements and how they can be applied in residential construction.

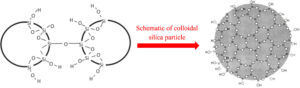

GFRP Reinforcing Bars for Concrete Construction

ASTM A615 “Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement” outlines the material specification requirements for the most common type of steel reinforcement, while ASTM D7957 “Standard Specification for Solid Round Glass Fiber Reinforced Polymer Bars for Concrete Reinforcement” outlines physical, mechanical and durability properties for GFRP reinforcing bars. GFRP reinforcing bars are manufactured using a pultrusion process where strands of glass fiber are pulled through a vinyl ester resin bath and then through a die to mold the glass and resin material into bars that cure to solid form. This precision manufacturing ensures consistent performance, which is critical for structural reliability. While GFRP rebar was initially introduced through experimental applications over 30 years ago, the past decade has seen significant advancement driven by evolving material specifications, structural codes and design guides. These developments within the structural design community have enabled broader adoption across the industry.

Unlike steel reinforcing bars, GFRP reinforcing bars do not exhibit any yielding under load. GFRP reinforcing bars have a higher tensile strength but a lower tensile modulus. Additionally, they are lighter in weight (i.e., they weigh roughly one-third of the weight of steel bars), and the materials are non-ferrous, so there is no corrosion. As with any construction material it is critical to always require GFRP that meets or exceeds the relevant ASTM standards and specifications. Unfortunately, not all products on the market are fully compliant, so verifying adherence to ASTM D7957 is essential to ensure structural integrity and long-term performance.

Construction tolerances are generally specified according to ACI 117 “Specifications for Tolerances for Concrete Construction and Materials” making them the same as for steel reinforcing bars. The lighter weight makes the GFRP bars easier to handle. It is easier to cut, only requiring a small hand saw, and placing and tying follows with the same bar supports and ties as steel. Depending on your placing drawings, the GFRP bars may need to be tied or supported slightly more often based on their lighter weight (i.e. the bars can exhibit a tendency to float in freshly placed concrete) and flexibility (i.e., longer bars will have a tendency to deflect more under their own weight making supports more critical for clear cover). These practical differences in weight, handling and corrosion resistance are exactly what help crews reduce labor time, avoid rust-related issues and deliver cleaner, longer-lasting results.

Since the resin used in the bars cures during the manufacturing process, GFRP bars are not able to be bent in the field. Put another way, any bent shapes need to be formed in the bar in the manufacturing facility (like steel, prior to delivery at the job site in most markets). Because of this process the bends are exact, which we see as an advantage. The bars are formed around the necessary pins and cured in place meaning tolerances, shape and dimensions are exact and more importantly the same time after time. The manufacturing facility serves as mill and fabricator, in a sense, providing both bent and straight bars for the project. In some cases, for longer-legged bends, the bar will need to be supplied in two pieces and then lapped in the field. Lap lengths are generally longer than steel bars but like steel vary based on the design parameters of concrete strength, bar diameter, and so on. Calculations should be made for your specific design.

Today’s design codes — including ACI, IBC and the IRC — now speak GFRP. And the industry is listening.

Evolution of Design Codes for GFRP Reinforced Concrete Residential Walls

Generally speaking, ACI 332 “Code Requirements for Residential Concrete” covers the design and construction of residential concrete and is referenced and incorporated into the IRC (International Residential Code). ACI 318 “Building Code Requirements for Structural Concrete” is referenced and incorporated into the IBC (International Building Code) to cover building design apart from residential construction. When adopted by a jurisdiction, these Codes become part of the general building code and govern acceptable engineering design and practice.

One of the benefits of ACI 332 (compared to ACI 318) is that it simplifies the design process for several common residential structure configurations namely “one- and two-family dwellings, multiple single-family dwellings, townhouses and…cast-in-place footings, foundation walls and slabs-on-ground.” It offers prescriptive tables that detail the steel reinforcement needed according to the provisions of ACI 318 for a number of design parameters including wall height, concrete strength, wall thickness and maximum earth pressure of the soil. For these prescriptive conditions only, the need for a set of calculations sealed by a licensed design professional is eliminated.

When GFRP reinforcing bars were an emerging technology, the International Code Council Evaluation Services (ICC-ES) developed acceptance criteria for their use in concrete construction. Prior to the publication of ACI 440.11-22 code (more on that in a moment), fiberglass reinforcing would have been permitted under ICC Acceptance Criteria 454 “Fiber–reinforced Polymer (FRP) Bars for Internal Reinforcement of Concrete Members” which allows fiberglass reinforcing materials to meet certain requirements and then be an allowable alternative design to steel reinforcement. That was one path to use that required a full engineering design. Then, with the publication of ACI 440.11 “Building Code Requirements for Structural Concrete Reinforced with Glass Fiber-Reinforced Polymer (GFRP) Bars” in 2022, which was also referenced and incorporated into the IBC, GFRP reinforcing bars are allowed to be used more broadly via another path that requires a full engineering design.

Recognizing the ease of the ACI 332 prescriptive tables and related to the topic of GFRP reinforcement, NEx – An ACI Center of Excellence for Nonmetallic Building Materials recently published a comparable document for prescriptive residential design using GFRP reinforcement. MNL 6 “Recommended Practice Guidelines for FRP Bars in Pre-Engineered Projects” currently provides guidance connecting the principles outlined in ACI 440.11 to ACI 332. These tables outline reinforcement requirements in a similar format to ACI 332 for GFRP reinforcement meeting the ASTM D7957 material specification. For conditions not covered by these design parameters, of course, a licensed design professional could apply the strength and serviceability requirements in ACI 440.11.

Mateenbar took this one step further for ease of design and use by industry. Our ICC Equivalency Report 5548 “Fiber–Reinforced Polymer (FRP) Bars for Internal Reinforcement of Concrete Members” specifies allowable reinforcement with Mateenbar products for certain residential applications, the same as MNL 6 does in prescriptive tables, but specifically for Greenbar2X and Mateenbar60. The analysis behind the report takes full advantage of the Mateenbar properties, over and above the ASTM specifications.

Suffice it to say, the tools are in place today to use GFRP reinforcing bars without engineering calculations within the design parameters listed in our ICC Equivalency Report and MNL 6, but full design flexibility is also allowed with engineering calculations for structures outside of those limits according to ACI 440.11-22 under the IBC and IRC.

What’s more, ACI 332 committee members have approved revisions to ACI 332 such that GFRP will be included as an “approved material” in accordance with ASTM D7957 and ACI 440.11. This next edition of ACI 332 is scheduled to be published in 2026 and will be inclusive of GFRP reinforcing bars throughout. However, there will likely not be any prescriptive wall tables for GFRP within the code. As a side note, this is similar to the approval for fiber-reinforced concrete (FRC), which is also included in ACI 332 but without specific tables. This is an exciting development for the industry because it will enable GFRP to be used in all residential markets in the US immediately upon publication since ACI 332 is referenced by the IRC.

With industry-recognized standards now firmly in place—supported by ACI, ICC-ES, NEx and other leading organizations—the use of GFRP is no longer emerging, it is established. Contractors seeking to deliver longer-lasting, corrosion-resistant foundations now have the technical backing to do so with confidence. GFRP is ready for use today and worth considering for your next project.

About Mateenbar Composite Reinforcements, LLC

Mateenbar Composite Reinforcements, LLC produces two product lines of GFRP reinforcing bars – Greenbar2X™ and Mateenbar60™. Greenbar2X™ is perfect for residential projects like foundations, driveways, pool decks, patios, sidewalks and more. In addition, this flatwork product is ideal for light industrial projects like single-story buildings and vertical applications 10ft high or less. Greenbar2X™ is a lacquered, buffed and helically ground rib design, optimized for superior bond strength with concrete. The lacquer provides an additional barrier to the glass fibers in the bar (in addition to work gloves which would always be recommended practice on a construction site), as well as additional UV protection for the product. A distinctive green color enhances visibility and worker safety on construction sites. So, whether you’re forming walls, pouring footings or laying slabs, Greenbar2X™ delivers proven performance, a lighter lift and the durability to outlast steel where it matters most – on your jobsite.

Designed for heavy industrial projects and larger structural applications, Mateenbar60™ is a dependable choice for bridges, multi-story buildings and other demanding infrastructure projects. For both products, the innovative form factor (i.e., the surface preparation that enables the bond to the surrounding concrete) ensures a long shelf life without deterioration and makes for easy handling. As highlighted previously, prefabricated bends are available by order to accompany both products, offering added versatility for customized project needs and making it easier to meet specific design requirements.

Mateenbar® products can be found wherever you currently purchase your construction materials and reinforcing bars. Greenbar2X™ and Mateenbar60™ are sold nationally in “big box stores” including Lowe’s and Home Depot, both in-store and online, a rare achievement in the reinforcement space. The products are also distributed by leading national and regional partners serving infrastructure, commercial and industrial sectors across the US. All products are backed by expert support and inventory across multiple regions to meet demand for large scale, time-sensitive projects.

A Note about Price Stability and Tariffs

The price of the component materials of GFRP reinforcement is relatively stable, unlike steel whose pricing can vary considerably over time based on scrap prices and demand, seasonal variability and other market forces. Advances in manufacturing technology have also resulted in efficiencies that have and will continue to ultimately lower the unit price for GFRP. Our manufacturing plant, located in Concord, North Carolina (just outside of Charlotte), is fully Build America, Buy America (BABA) compliant. While BABA compliance is not currently mandated for residential construction, we view it as both a responsibility and a point of pride. At Mateenbar®, we believe in reinforcing the important things in life — from connecting communities and supporting contractors, to being responsible contributors to the places we live and work. Our commitment to domestic manufacturing ensures that every product we make strengthens not just structures, but the long-term resilience of American infrastructure and the people who depend on it, like you!

GFRP Reinforcing Bars

– lightweight, competitive price point and non-corrosive –

an appealing alternative for your next project!

About the author: Danielle Kleinhans is Director of Engineering and Business Development for Mateenbar Composite Reinforcements, LLC located near Charlotte, North Carolina. In this role, she is tasked with educating the design and construction community about GFRP reinforcing use in concrete nationwide. She has over 20 years of experience in structural engineering and association management. Prior to joining Mateenbar®, she worked for the Concrete Reinforcing Steel Institute (CRSI), where she most recently served as President and CEO. Before that, she worked at CTLGroup focusing on forensic engineering and at Modjeski and Masters as a structural bridge design engineer. She earned a bachelor’s degree in civil engineering from the University of Alaska-Fairbanks, and a master’s degree and PhD in civil engineering from the University of Missouri-Rolla. She serves on numerous industry committees related to reinforced concrete construction, is a licensed professional engineer and a fellow of the American Concrete Institute.

The Limits of Colloidal Silica for Concrete Densification, Strength and Abrasion Resistance

By Derick Rainey, Vice President Nox-Crete Inc.

This white paper has been reproduced with approval from Nox-Crete Inc.

Executive Summary