2025 Projects of the Year: The Category Winners

The 26th annual Concrete Foundations Association (CFA) competition invited members to showcase their most outstanding projects, competing for recognition as some of the most celebrated achievements in the industry’s history. The entries, a collection of 24 unique and intricate submissions, spanned 11 categories, ultimately resulting in 14 projects being honored this year.

While the projects themselves are the centerpiece of this program, the accompanying statistics highlight the Association’s leadership and the remarkable milestones achieved. Representing 13 U.S. states and one Canadian province, the entries came from locations as diverse as Utah and California in the West, Connecticut and Rhode Island in the East, British Columbia in the North, and Texas and Georgia in the South. A total of 15 members contributed to this year’s submissions, demonstrating the widespread participation and commitment of CFA members. The projects varied significantly in scale, with the largest covering 14,760 square feet of building area and the smallest just 111 square feet. One particularly impressive project utilized nearly 1,130 cubic yards of concrete and 186,186 pounds of steel reinforcement. Altogether, the competition saw the use of 8,590 cubic yards of concrete and 889,161 pounds of steel reinforcement, along with numerous other essential materials, underscoring the scale and complexity of the work submitted.

For many CFA members, this awards program serves as a vital platform for marketing their companies and showcasing their expertise. Longtime participants include Herbert Construction Company of Marietta, Ga., SCW Footings and Foundations of Salt Lake City, Utah, Custom Concrete of Westfield, Ind., Talpey Construction, LLC of Old Saybrook, Conn., and Ekedal Concrete, Inc. of Irvine, Ca. These companies, among others, recognize the value of the CFA in promoting the exceptional quality of their work and gaining industry recognition.

“It’s incredible to witness the growth of the Projects of the Year awards program over the years,” said James Baty, executive director of the CFA. “In 2020, we celebrated six winners and now, just five years later, we’re recognizing fourteen projects. This growth reflects the enthusiasm of our members to share the innovative and unique work they’re doing.”

Baty also emphasized the high standards set by CFA members, saying, “Each year, I’m inspired by how our members continue to raise the bar for quality and technological advancements in the cast-in-place industry. These awards are a testament to their innovation, craftsmanship and creativity, which are on full display in every project submitted.”

Grand Project of the Year: Single Family 5,001 to 10,000 Sq. Ft.

Mills Foundations

Parsons Residence – Stonebridge Subdivision

Branson West, Missouri

This single-family home serves as a prime example of advanced construction methods and innovative problem-solving to overcome challenging site conditions. The project under-scores the importance of meticulous planning and technical precision in residential builds.

Spanning 5,300 square feet, the poured wall system was custom-engineered to accommodate a dramatic 35-foot elevation difference on the property. To ensure structural stability and seamless integration, the foundation incorporated 32 continuous footing steps.

The team constructed structural and retaining walls reaching up to 20 feet in height. These elements required 197.25 cubic yards of concrete and 6,000 pounds of reinforcing steel, emphasizing the scale and complexity of the project.

To stabilize the site, approximately 200 linear feet of retaining walls were built, balancing both structural integrity and functional design. Additionally, 141 linear feet of stacked forms were employed to construct walls up to 20 feet high, addressing the steep elevation changes. A three-level elevator shaft was also embedded into the poured wall system, showcasing the team’s ability to coordinate intricate structural elements with precision.

The construction process faced challenges from high-temperature conditions. To ensure the concrete remained workable and structurally sound, a retarder and super plasticizer were added to the mix. This adjustment extended the finishing time while preserving the quality of the concrete.

Efficient on-site operations were achieved through streamlined material deliveries and close collaboration between subcontractors.

This project offered several key insights. The stepped foundation provided a practical solution for extreme elevation changes, while heat-resistant concrete, achieved through mix modifications, successfully addressed environmental constraints. Furthermore, integrating structural components like retaining walls and the elevator shaft optimized both functionality and design, resulting in a highly efficient and durable build.

Single Family Foundation <2,000 Sq. Ft.

Uni-Foundations Inc.

Lake Holiday Project

Cross Junction, Virginia

The project involved constructing a compact residence on a steeply sloped site, necessitating innovative approaches due to significant elevation changes. The foundation included footings with a 12-inch thickness. Exterior footings measured 36 inches wide, while interior footings were 24 inches wide. A total of ten stepped footings ranged from one to five feet in height. Fiberglass reinforcement, specified per the homeowner’s request, was utilized throughout, eliminating the need for traditional steel reinforcement.

The walls varied significantly in height and thickness to adapt to the terrain. Heights ranged from 32 feet at the tallest exterior sections to 25 feet, with interior walls spanning from nine feet to a minimum of three feet. The wall thicknesses were between ten and 24 inches, showcasing precision in structural adaptation. The total volume for wall concrete was approximately 130 cubic yards.

Of notable complexity was the parking area retaining wall, which supports a walking bridge providing the sole access to the residence. This feature required meticulous planning and placement, adding 80 cubic yards of additional concrete. Limited site access demanded manual transport of formwork and materials, supplemented by crane use where feasible. This project achieved engineering excellence by addressing unique challenges and delivering a high-quality result tailored to the site’s demanding conditions.

Single Family Foundation 2,000-5000 Sq. Ft.

MJ Lorenz Concrete

Christmas Lake Curve

Shorewood, Minnesota

This residential project consisted of constructing a cast-in-place concrete foundation that required 207 cubic yards of concrete and 8,000 pounds of reinforcing steel. The footings, measuring 20 inches to 24 inches wide and ten inches thick, included two #4 continuous rebar and structural bulkheads to manage multiple elevation changes. Forming techniques for the curved wall footing utilized short board sections for precise shaping.

The walls, with varying heights of 4 feet, 10 feet 9 inches, 11 feet 9 inches, 13 feet, and 14 feet 7 inches, featured thicknesses of 8 feet, 10 feet, and 14 feet. A curved wall with a pre-cast bearing ledge and an exterior brick ledge presented unique challenges. Insulation foam was cut and mitered to create seamless ledges, and one-sided wall ties were implemented due to intricate detailing. Total Station technology was employed for precise layout of the curved wall and framing lines post-pour.

Despite the complexities, the entire wall assembly was achieved in a single pour, meeting both safety and scheduling targets. This meticulous approach ensured alignment with the general contractor’s timeline. The project demonstrated proficiency in handling complex geometries, implementing advanced layout techniques and coordinating detailed reinforcement and formwork solutions to deliver a high-quality structure ready for framing.

Single Family Foundation 10,000-15,000 Sq. Ft.

Herbert Construction Co.

Lake Rabun Hose

Lakemont, Georgia

This construction project features a residential property with intricate technical demands, successfully addressed through precise planning and innovative techniques. The total project spanned 14,760 square feet, utilizing 1,130 cubic yards of concrete and a reinforced steel framework weighing approximately 186,186 pounds, categorized by #4, 5, 6, 7 and 8 rebar sizes. Wall heights reached up to 35 feet, with varying thicknesses and complex configurations, including radius and sloped designs.

Eighty-eight distinct footing details were incorporated, including 34 step footings totaling nearly 62 linear feet, with precise elevation control. The project required 23 concrete pours and included multiple top-of-wall elevations, creating structural intricacies demanding continual adjustment.

Custom innovations included Hancock-style brackets, facilitating the second and third wall lifts, and enhanced by integrated OSHA-compliant scaffolding. The steep site necessitated phased construction and precise logistics. Each phase featured waterstop integration at key joints to ensure durability and water resistance.

Challenges included managing plan modifications during construction, fostering close collaboration among architects, engineers, and subcontractors. Computer-aided design (CAD) drawings supported detailed planning, while specialized materials, such as an acrylic fortifier at control joints, enhanced durability. Despite tight conditions and remote access, the team executed the project with technical precision, achieving an outstanding residential structure that exemplifies high-quality craftsmanship.

Non-Foundation Structural Element

SDP Concrete Ltd.

Walls to Nowhere

Coquitlam, British Columbia, Canada

The project involved constructing cast-in-place concrete walls with a total volume of 32 cubic yards, featuring 15 cubic yards allocated to footings and 17 cubic yards for walls. The footings were designed with precision, featuring dimensions of 2 feet by 10 inches. Additional complexity was introduced by double-stacking two-by-ten wooden planks in some areas and stacking a two-by-four atop a two-by-ten in others. Steps ranged from five feet to 8 feet 7 inches wide and 32 inches high.

Wall structures were designed at eight-inch thickness with heights under ten feet. Unique features included five rake walls extending 12inches above future stair nosings and angles such as 53-, 58- and 45-degreecorners. State-of-the-art formwork techniques were employed, including beveled plywood for seamless joints and chamfer strips for clean, visible edges. Ensuring an architectural finish, walls were formed using new paper-faced plywood, snap ties, and 2x lumber.

Key processes involved CAD-based 3D modeling for precise layouts, robotic total stations for accurate positioning and collaboration with GPS-enabled excavation tools. Despite challenges including warped plywood, the team achieved tight deadlines within 13 days, demonstrating exceptional foresight, craftsmanship and efficient resource use. This project displays meticulous attention to detail, ensuring both technical precision and aesthetic excellence.

Above-Grade Concrete Home

Origin Concrete, Inc.

Summer Residence

Malabar, Florida

This residential project spans 9,496 square feet and utilizes 438.5 cubic yards of concrete, reinforced with 47,000 pounds of steel. The wall structures are notably complex, with heights ranging from four to 41 feet and thicknesses of six, eight and 12 inches. The construction integrates six cantilevered wall areas and a cantilevered deck positioned 32 feet above ground level. Additional features include radius site walls, cantilevered beams and numerous precision openings requiring tight tolerances.

The project utilized advanced materials and systems to achieve its objectives. All forming was executed using custom-engineered formwork systems. Reinforcement was tied with automated rebar-tying tools to enhance efficiency and consistency.

The concrete incorporated micro-reinforcement for improved strength and durability, and pumping was facilitated by high-capacity equipment. Control joints were completed using specialized waterproofing products to ensure longevity and performance under varying conditions.

Exceptional planning and collaboration were key to addressing technical challenges, with input provided at the design stage to refine structural solutions. This residence exemplifies resilience and architectural versatility, demonstrating the potential of concrete to realize highly intricate designs. By leveraging innovative materials and techniques, the project offers a durable, disaster-resistant housing solution that meets both functional and aesthetic criteria.

Above-Grade Commercial Concrete Project

Fox Blocks

White Shield Old Scouts Veterans’ Memorial Center

White Shield, North Dakota

The project features a 12-sided dodecagon structure spanning 10,900 square feet of insulated concrete form (ICF) walls, emphasizing precision and innovation. This design required exact angular measurements for all 12 corners, ensuring structural integrity and achieving a geometry inspired by traditional construction techniques.

The ICF system provided continuous double-layer insulation, integrated fastening strips and a reversible interlock system. These features minimized thermal bridging while enhancing structural performance. Glued laminated timber (glulam) embed plates were incorporated within the walls to anchor the roof structure. The roof’s structural system included a central compression ring and a custom geo-dome skylight, ensuring efficient load distribution and maximizing natural light.

Specialized earth berms along the exterior served as additional insulation, while improving the building’s energy performance and visually integrating it with its surroundings. These design choices enabled a 35-percent reduction in Energy Use Intensity as well as optimized thermal efficiency for harsh climates.

Construction was completed in 25 days for the ICF walls, saving approximately 40 days compared to traditional methods and reducing costs by $120,000 during extreme winter conditions. The project demonstrates the adaptability and efficiency of advanced formwork systems, achieving sustainability and durability while meeting cultural and technical complexities with innovative solutions.

The Rest of the Best

Along with the category winners, seven additional projects received high enough evaluation scores to be named award recipients this year. Six amazing projects by SCW Footings & Foundations of Salt Lake City, Utah, were deemed exceptional: Nocek Residence, Fox Mountain Retreat, Marshall Pavilion, Hyde Residence, Velvaere Lot 27 and Cutler Residence. Fox Blocks, Omaha, Neb., also had the highly rated Texas Ranch House. The fun of CFA awards season doesn’t stop here; in the winter issue of Concrete Facts, we will be covering the “rest of the best” of the project award winners.

2025 CFA Directorio de productos y servicios

Alliance Concrete Pumps

Alliance Concrete Pumps fabrica una línea completa de bombas de pluma de concreto montadas en camión, bombas de línea y plumas distribuidoras para la industria de la construcción. Conocidas por su fiabilidad y rendimiento, las bombas Alliance están diseñadas con controles fáciles de usar y componentes robustos para una durabilidad a largo plazo. Con un énfasis en el servicio posventa y de servicio de asistencia técnica, proporcionan a los contratistas con las herramientas y la confianza para hacer el trabajo de manera eficiente. Alliance sigue innovando para satisfacer las necesidades cambiantes de los profesionales del concreto en toda Norteamérica.

AutoCar

En Autocar, no sólo fabricamos camiones, sino que es nuestra forma de vida. Autocar es uno de los principales fabricantes estadounidenses de camiones profesionales para tareas pesadas para usar como grúas móviles, tractores de terminal y chasis de bombas de pluma para concreto. Podríamos decir muchas cosas rimbombantes sobre nuestra investigación y tecnología. Podríamos hablar de nuestra experiencia. Podríamos hablarle de nuestro servicio de atención al cliente. Probablemente sea lo que espera, pero todo eso lo encontrará en nuestras páginas web. No estamos aquí para dormirnos en los laureles. Para entender de verdad a Autocar, todo lo que necesita saber es que estamos centrados al 100 % en aplicaciones especializadas porque sabemos que usted también lo está.

Badger Forms

Badger Forms suministra encofrados de aluminio y accesorios para los sectores industrial, comercial, residencial y de prefabricados. El único objetivo de Badger Forms es proporcionar a nuestros clientes encofrados y accesorios tecnológicamente avanzados, extremadamente duraderos y altamente eficientes. Todos los encofrados Badger se producen en una fábrica con certificación ISO, que actualmente produce más de 40 000 pies cuadrados de encofrado al día con capacidad adicional disponible. Esta planta de fabricación de primera categoría está equipada con maquinaria de última generación y avances tecnológicos que no están al alcance de las empresas más pequeñas. Esta capacidad de fabricación de alta tecnología permite a Badger Forms satisfacer rápidamente las necesidades de los clientes.

BIK Boom Trucks

Durante más de 30 años, BIK Boom Trucks ha sido un líder y pionero en brindar soluciones en camiones pluma a medida de la más alta calidad en América del Norte para contratistas de pared o cimentación vertida, e industrias de concreto prefabricado. BIK ha instalado y montado más de 2000 descargadores articulados con brazo tipo ‘knuckle’, montados en la parte trasera. BIK se enorgullece de presentar la nueva grúa de encofrado de la serie BIK, la FC-67. Se trata de la descargadora de pluma más innovadora y simplificada para contratistas de cimentaciones que funciona con una velocidad máxima y una productividad insuperables. La red nacional de distribuidores de BIK y la línea directa de asistencia técnica para grúas, disponible todos los días de la semana, garantizan una asistencia posventa de primer nivel. «No se conforme con menos, compre al mejor».

Boman Kemp Manufacturing, Inc.

Boman Kemp Manufacturing, Inc. ha crecido hasta convertirse en uno de los principales fabricantes en el ámbito de las barras de refuerzo, el acero estructural y las ventanas de salida para sótanos. Gracias a nuestra sólida red de distribuidores repartidos por los EE. UU. y Canadá, no importa dónde se encuentre, los productos de primera calidad están a su alcance. Con un legado basado en un compromiso inquebrantable con la calidad, hemos grabado nuestro nombre como la elección de confianza para innumerables proyectos de construcción, grandes y pequeños, desde 1967.

BuildBlock Systems

BuildBlock es un fabricante líder de encofrados de concreto aislado (ICF, por sus siglas en inglés), que ofrece una gama completa de soluciones de construcción duraderas y energéticamente eficientes para proyectos residenciales y comerciales. Sus ICF proporcionan un aislamiento, insonorización y resistencia superior mientras reducen el tiempo de construcción y los residuos. BuildBlock apoya a los contratistas con formación completa y recursos de diseño para asegurar el éxito del proyecto. Sus productos son reconocidos por su diseño de interconexión fácil de usar y su rendimiento a largo plazo.

CanAmerican Stone Spreader

CanAmerican es el único fabricante de esparcidores de piedras que utiliza sus propios camiones a diario. Dependemos de la durabilidad y fiabilidad de nuestros equipos, que dio lugar al desarrollo de la marca SOILKING. Nuestra innovación consolidó nuestro liderazgo en el sector y es evidente en nuestra nueva generación de SOILKING Extreme. El diseño exclusivo del Extreme combina seguridad, durabilidad y versatilidad. La plataforma de la Extreme, que se eleva y desciende mediante un sistema hidráulico remoto, reduce el centro de gravedad al conducir o maniobrar la unidad, tanto si se está esparciendo material como descargando material utilizando el fondo alimentador.

Cemen Tech

Cemen Tech es el mayor fabricante mundial de mezcladoras volumétricas y ofrece soluciones móviles y fijas que permiten una producción de concreto precisa y por encargo. Sus mezcladoras ayudan a eliminar residuos, reducen el tiempo de inactividad y ofrecen a los contratistas la flexibilidad de producir diferentes mezclas en el lugar. Cemen Tech también ofrece tecnología registrada como ACCU POUR para la gestión remota de proyectos y flotas. Sus equipos son ideales para mejorar la eficacia, la calidad y la rentabilidad de las operaciones de concreto.

Chatterton Construction Supply

Somos el distribuidor en el oeste de EE. UU. de tirantes de moldes y herramientas de 4 Seasons. Nuestro objetivo número uno es ayudarle a hacer crecer su empresa. Utilizando nuestro conocimiento de la industria, podemos ayudarle a maximizar su producción. Contamos con una variedad de productos que pueden ayudarle a finalizar sus trabajos más rápido. Para nombrar sólo unos pocos: liberación de encofrado, herramienta inalámbrica para amarre de barras de refuerzo, sierras inalámbricas para barras de refuerzo, cestas para grúa, ventanas para vertido en el lugar, marcos troquelados de aluminio para ventanas, huecos para ventana y suministros de construcción en general. Sea lo que necesite, lo más probable es que lo tengamos o sepamos dónde conseguirlo.

Concrete Forms Services (EZ-Footings)

Aquí en EZ-Footings™ hemos diseñado encofrados de concreto precisos de aluminio ligero y muy fuerte. Con estos encofrados de zapatas puede tener un sistema de encofrado de concreto que se ensambla fácilmente a presión, que reducirá sus costos de mano de obra hasta en un 50 %. Además, también ahorrará en concreto, madera, clavos y combustible para transportar el equipo. Hemos pensado en todo para mejorar la simplicidad, y sus resultados finales serán mejores de lo que jamás haya visto.

Cranes & Equipment Corp

Grúas para transporte de encofrados Copma totalmente hidráulicas. Sin electrónica, sin sensores, sin ordenadores. Grúas con o sin torre disponibles, con alcances de 66 a 84 pies y capacidades máximas de 1800 a 2300 libras. ¿Necesita una grúa más grande o más pequeña? Podemos proporcionársela. La grúa torre Copma 450 ofrece opciones de alcance y elevación de 2250 libras a 70 pies y 8 pulgadas, 2000 libras a 78 pies y 9 pulgadas o 1800 libras a 84 pies y 8 pulgadas. Visite el pabellón #C4834 de Cranes & Equipment en el WOC. Pregunte por nuestras ofertas especiales y descubra nuestro paquete para transporte de encofrados con la Copma 450.6J3.

CrewTracks

CrewTracks es una plataforma de software de gestión de la construcción diseñada para simplificar la comunicación, el horario y la documentación de los equipos de campo y de oficina. Creada pensando en la industria del concreto, la aplicación permite el seguimiento en tiempo real de la mano de obra, la producción, los equipos y los materiales. Los contratistas pueden agilizar el pago de salarios, mejorar la visibilidad del proyecto y eliminar el papeleo con tarjetas de registro de horas digitales e informes diarios. CrewTracks mejora la eficiencia del lugar de trabajo y proporciona información para tomar decisiones de manera informada.

DMX Membranes Limited

DMX Membranes Limited fabrica productos innovadores de impermeabilización y drenaje que protegen los cimientos de concreto de los daños causados por la humedad. Sus productos insignia DMX AG™ y DMX Drain 5X™ proporcionan un alto nivel de protección y son fáciles de instalar en proyectos residenciales y comerciales. Las membranas DMX, conocidas por su durabilidad y rendimiento, prolongan la vida útil de los sistemas de cimentación mientras que ayudan a cumplir los requisitos de los códigos de construcción modernos. Los contratistas confían en DMX para soluciones de impermeabilización a largo plazo y sin mantenimiento.

DY Concrete Pumps

DY Concrete Pumps ofrece una línea completa de bombas de pluma montadas en camión y bombas de línea diseñadas para ofrecer fiabilidad, facilidad de uso y una larga vida útil. Disponibles en una amplia gama de tamaños y configuraciones, las bombas DY están construidas para desempeñar todo tipo de trabajos, desde losas residenciales hasta complejos vertidos comerciales. Con el respaldo de un centro de servicio especializado, un amplio inventario de piezas y un servicio técnico que responde, DY se compromete a prestar asistencia a sus clientes en toda Norteamérica.

EPRO Services, Inc.

EPRO proporciona una protección total de la envoltura del edificio para cualquier condición del sitio, en cualquier lugar. Durante 30 años, hemos desarrollado amplios sistemas de impermeabilización y mitigación de vapor para proyectos en todo Estados Unidos y Canadá. Comprendemos que las condiciones del lugar y los objetivos de rendimiento pueden variar de un proyecto a otro, ofrecemos opciones que permiten a los equipos de diseño sopesar los pros y los contras de cada material a la hora de seleccionar un sistema que satisfaga sus necesidades. Con sistemas garantizados de impermeabilización y barrera contra contaminantes, ePRO tiene como meta ser el único proveedor para proyectos de construcción de principio a fin.

Euclid Chemical

Durante más de 100 años, Euclid Chemical ha sido un proveedor líder de la industria del concreto y la albañilería, ofreciendo una línea completa de aditivos para concreto y productos de construcción, incluyendo aditivos químicos, aditivos para bloques y albañilería, fibras, compuestos de endurecimiento y sellado, adhesivos epoxi, revestimientos para suelos y paredes, lechadas estructurales para columnas, equipos y maquinaria, rellenos para juntas y productos de reparación. Las fibras macrosintéticas TUF-STRAND SF de Euclid Chemical pueden utilizarse para sustituir el refuerzo de acero convencional en sistemas de muros vertidos y otras estructuras de concreto con cálculos de ingeniería estudiados y servicios de diseño profesionales.

Ferrosource LLC

Ferrosource LLC es un proveedor de productos de acero de refuerzo de alta calidad para la construcción con concreto. Ofrecen una amplia gama de barras de refuerzo, mallas y accesorios que cumplen con las especificaciones ASTM y los requisitos del proyecto. Ferrosource LLC se centra en la entrega rápida, precios competitivos y servicio centrado en el cliente. Su equipo trabaja en estrecha colaboración con los contratistas para garantizar que los materiales adecuados estén en el sitio, a tiempo y listos para funcionar.

Form-A-Drain

Form-A-Drain es un sistema de encofrado de zapatas de concreto premontado y fijado, que también sirve como solución de drenaje de cimientos y ventilación de radón. Elimina la necesidad de utilizar encofrados de zapatas y tubos de drenaje perforados por separado, ahorrando tiempo y trabajo en el sitio de trabajo. Form-A-Drain ayuda a los contratistas a cumplir con los códigos de la edificación con mayor facilidad y mejora el rendimiento general de la obra. Es una solución inteligente y eficaz para cimentaciones residenciales y comerciales ligeras.

Fox Blocks

Tras décadas de experiencia e innovación en la industria del ICF, Fox Blocks respalda los productos con el apoyo, el servicio y la entrega que esperan constructores y diseñadores. En 2006, después de 20 años de producir todas las marcas de ICF, Airlite introdujo la marca Fox Blocks ICF como la última generación de encofrado de concreto aislado disponible del fabricante al mercado.

Giatec Scientific

Giatec Scientific es líder en tecnologías inteligentes de pruebas de concreto y ofrece sensores inalámbricos y software basado en IA para supervisar la resistencia, la temperatura y la madurez del concreto. Sus sensores SmartRock proporcionan datos en tiempo real para mejorar los plazos de los proyectos y reducir los costosos retrasos. Las soluciones de Giatec se utilizan en todo el mundo para mejorar el control de calidad y optimizar el rendimiento del concreto.

GluDown Inc.

GluDown Inc. ofrece soluciones adhesivas avanzadas diseñadas específicamente para el sector de la construcción. Sus adhesivos de alto rendimiento se utilizan para fijar membranas impermeabilizantes, aislamientos y otros materiales. Los productos de GluDown están diseñados para conseguir uniones fuertes y duraderas, y una aplicación eficaz. Los contratistas confían en GluDown para realizar instalaciones más limpias y rápidas y reducir los costos de mano de obra.

GMX Inc.

Mejor drenaje, durabilidad superior, precio competitivo, ecológico, flexible y se dobla fácilmente. ¡Y no produce comezón! ¿Qué más hay que decir? Los paneles de protección de fibra de vidrio no pueden igualar el nivel de excelencia de Thermal Drain de GMX. Thermal Drain se puede pedir en versiones R-3, R-5 y R-10 con grosores de 3/4, 1-3/16 y 2-3/8 pulgadas. GMX fabrica sistemas de impermeabilización para el mercado residencial y una línea completa de productos y sistemas de impermeabilización comerciales. Desde 1895, GMX ha proporcionado soluciones para los problemas de impermeabilización más desafiantes. Aceptamos con agrado la oportunidad de poner nuestra experiencia a su servicio.

Gravel Conveyors Inc.

Gravel Conveyors Inc. ofrece sistemas móviles de esparcidor de materiales que los reparten de forma precisa y eficiente en el lugar de trabajo. Su equipamiento reduce el trabajo manual y mejora la productividad mediante la colocación de grava, arena o tierra exactamente donde se necesita. Ofrecen una gran variedad de modelos de transportadores, incluidas unidades montadas en camiones e independientes. Sus soluciones son ideales para proyectos de concreto, paisajismo y servicios públicos.

Helix Steel

Helix™ Steel es el fabricante de micro armadura de acero retorcido (TSMR, por sus siglas en inglés), la tecnología proactiva de refuerzo de concreto líder en el mundo. TSMR ha conseguido la UES ER-279 de IAPMO y es el único producto de refuerzo de concreto discontinuo con una certificación ISO 9001: Certificación 2015 por su Sistema de gestión de calidad. El TSMR se utiliza en mercados como el comercial, el industrial, el de prefabricados, el residencial, el subterráneo y el de infraestructuras, y se emplea en distintas aplicaciones como muros bajo y sobre rasante, losas sobre rasante, losas sobre cubierta y pavimentos, proporcionando refuerzo estructural, resistencia a la temperatura y a la contracción, a las fisuras, a los movimientos sísmicos, a los impactos y a las explosiones.

Hippo Technologies, Inc.

Fundada en 2020, Hippo Technologies ha desarrollado soluciones avanzadas de RA para la construcción y la sanidad. La empresa ha desarrollado su propio software patentado y puede utilizar varios dispositivos para organizarlo, incluidos diversos auriculares manos libres activados por voz, teléfonos celulares y tabletas. El conjunto de productos de Hippo para la construcción e industrias afines se llama Hippo Virtual Expert (HVE) y se utiliza para diseño y construcción, recuperación de desastres y equipos pesados.

ICC Distribution Group LLC

ICC Distribution Group LLC suministra una amplia gama de productos innovadores para la construcción, incluyendo aislamiento, impermeabilización y accesorios para el concreto. Representan a fabricantes de primer nivel y atienden a los contratistas con el conocimiento experto del producto y la entrega rápida. ICC se especializa en soluciones energéticamente eficientes y que cumplen con los códigos tanto para aplicaciones residenciales como comerciales. Es un socio de confianza para materiales de construcción de alto rendimiento.

Irving Equipment

Irving Equipment es un distribuidor líder de equipamiento de colocación y bombeo de concreto, incluidas bombas de concreto montadas en camiones, plumas distribuidoras y bombas de remolque. Representan a los principales fabricantes y ofrecen asistencia amplia , incluida la formación, piezas y mantenimiento. Su dedicación a maximizar el tiempo de uso y el rendimiento en el lugar de trabajo les ha convertido en un nombre de confianza entre los contratistas de concreto de todo el país.

Irving Materials Inc.

Irving Materials Inc. (IMI) es un proveedor líder de concreto preparado, agregados y materiales de construcción en todo el Medio Oeste y el sur de EE. UU. Ofrecen diseños de mezcla personalizados, entrega a tiempo y experiencia en la industria para una amplia gama de proyectos de construcción. IMI está comprometida con la calidad, la seguridad y la sostenibilidad en cada lote de concreto que produce. Su amplia red garantiza un suministro fiable y asistencia a los contratistas de todos los tamaños.

I-State Truck Center de Marshfield WI

I-State Truck Center de Marshfield, WI, ofrece ventas de camiones para tareas pesadas, servicio y piezas para marcas líderes como Freightliner y Western Star. Apoyan a la industria del concreto con vehículos confiables adaptados para la entrega de materiales y las demandas de la construcción. Su equipo ofrece mantenimiento preventivo, servicio de emergencia y soluciones personalizadas. I-State es conocido por su compromiso con el tiempo de uso y la satisfacción del cliente.

Mar-Flex Waterproofing & Building Products

Los rollos de drenaje GeoMat+ y GeoMat eliminan el agua y resisten la presión hidrostática canalizando el agua bajo rasante hacia los sistemas de drenaje de las zapatas. Estos canales de agua se crean moldeando polietileno de alta densidad (HDPE) en láminas con hoyuelos alineados de manera vertical y horizontal, que actúan como barrera para proteger las membranas líquidas contra la tierra de relleno y los sedimentos. La línea de productos GeoMat puede complementar y proteger una membrana impermeabilizante o antihumedad en aerosol. En los casos en que se instala un sistema de drenaje, GeoMat puede utilizarse como producto antihumedad además de como membrana impermeabilizante. Los accesorios GeoMat están disponibles para facilitar cualquier trabajo y hacen que la instalación sea sencilla.

Mateenbar Composite

Mateenbar Composite fabrica barras de refuerzo de polímero reforzado con fibra de vidrio (GFRP, por sus siglas en inglés) de alta resistencia a la corrosión. Sus productos se utilizan en aplicaciones en las que la barra de refuerzo tradicional puede deteriorarse con el tiempo. Mateenbar ayuda a prolongar la vida útil de las estructuras de concreto y reduce los costos de mantenimiento. Proporcionan asistencia de ingeniería y soluciones conformes con los códigos para la construcción sostenible.

MAX USA Corp.

MAX USA Corp. desarrolla y fabrica herramientas de construcción de calidad profesional, incluidas atadoras de alambre para barras de refuerzo, compresores y clavadoras. Las atadoras de alambre para barras de refuerzo a batería son conocidas por su velocidad, durabilidad y diseño ergonómico. Las herramientas MAX aumentan la productividad en la obra y reducen el esfuerzo de los trabajadores. Son una marca de confianza para los contratistas de concreto y cimentaciones de todo Estados Unidos.

Monarch Materials Group

Monarch ofrece una completa selección de productos para sótanos y salidas que hacen que la experiencia de compra sea fácil y eficaz. Ofrecemos una gran variedad de ventanas, marcos, pozos, recubrimientos y accesorios que se integran en el sistema para instalaciones personalizadas. Convertimos sótanos nuevos y existentes en áreas de estar hermosas y cálidas realzadas con luz solar natural. Los productos Monarch cuentan con la certificación Energy Star y cumplen con los códigos de salida IRC.

Mono Slab EZ Form

Mono Slab EZ Form es un sistema de encofrado que simplifica la construcción de losas monolíticas, combinando el encofrado y el aislamiento en un solo paso. Esta innovadora solución reduce el tiempo de preparación, la mano de obra y el desperdicio de material. El sistema cumple con los requisitos del Código de edificación y es compatible con la construcción energéticamente eficiente. Los contratistas aprecian su facilidad de uso y sus ventajas de rendimiento en proyectos residenciales y comerciales ligeros.

MST Bar USA

MST Bar USA produce barras de refuerzo de GFRP de alto rendimiento como alternativa ecológica a las barras de acero. Sus barras de refuerzo ofrecen una excelente fortaleza, resistencia a la corrosión y durabilidad a largo plazo. MST Bar es ideal para aplicaciones marinas, de transporte y de servicios públicos en las que las barras de refuerzo tradicionales pueden fallar. Su compromiso es ofrecer soluciones innovadoras para el refuerzo del concreto.

Multiquip Inc.

Multiquip Inc. ofrece una amplia gama de equipamientos de construcción, incluyendo mezcladoras, vibradores, paletas eléctricas y generadores. Sus productos son confiables por su fiabilidad y rendimiento en sitios de la obra de todos los tamaños. Multiquip atiende las necesidades de los contratistas de cimentaciones con herramientas innovadoras que mejoran la eficiencia y la calidad del acabado. Respaldan sus equipos con un sólido servicio de asistencia y piezas de repuesto.

New York Poly Steel

New York Poly Steel fabrica sistemas ICF diseñados para crear estructuras energéticamente eficientes y resistentes a catástrofes. Sus bloques son fáciles de instalar y proporcionan un aislamiento térmico y acústico superior. La empresa respalda a los contratistas con formación sobre productos, servicios de diseño y asistencia en el sitio. Son firmes defensores de las prácticas de construcción ecológicas y resistentes.

Nox-Crete Inc.

Ahora es un buen momento para limpiar sus encofrados de aluminio… ¡de la forma más fácil! El otoño y el invierno son un buen momento para empezar a pensar en cómo eliminar la acumulación de concreto duro de sus encofrados de aluminio. Form Clean es un producto potente, químicamente activo y de doble uso, diseñado para ablandar rápidamente las acumulaciones de concreto duro y, también, actúa como agente desmoldante. El uso de Form Clean como sustituto de su agente desmoldante habitual durante dos a tres semanas suele ser suficiente para eliminar gran parte de las acumulaciones de concreto. Una vez que sus encofrados estén limpios, puede volver a utilizar su desmoldante habitual. Si sus encofrados de aluminio juntan más acumulación, simplemente vuelva a utilizar Form Clean para ablandar y eliminarla.

OCM Inc.

OCM Inc. suministra una amplia gama de accesorios para encofrados de concreto, incluidos anclajes de los encofrados, soportes y herrajes. Atienden a contratistas de concreto residenciales y comerciales con productos fiables y de alta calidad. OCM ofrece entregas rápidas, precios competitivos y soluciones personalizadas para sistemas de encofrado. Su meta es hacer que el encofrado sea más seguro, rápido y eficiente.

O’Connor & Associates, Ltd

O’Connor & Associates es una empresa de consultoría y correduría de seguros al servicio de la industria de la construcción. Están especializados en gestión de riesgos, fianzas y soluciones de seguros adaptadas a los contratistas de concreto. La empresa ayuda a sus clientes a navegar por las complejas opciones de cobertura y a obtener tarifas competitivas. Su experiencia en el sector ayuda a reducir la responsabilidad y a proteger las operaciones de los contratistas.

Owens Corning

Owens Corning es líder mundial en aislamiento, techos y materiales compuestos de fibra de vidrio. Ofrecen soluciones energéticamente eficientes que mejoran el confort y la durabilidad de las estructuras de concreto. Owens Corning apoya a los contratistas con materiales de construcción de alto rendimiento y conocimientos técnicos. Sus productos contribuyen a una construcción ecológica y conforme a los códigos.

PALFINGER North America

PALFINGER North America fabrica equipamientos de elevación, carga y manipulación de materiales, incluidas grúas y elevadores de gancho. Sus soluciones montadas sobre camiones están diseñadas para ofrecer fiabilidad y productividad en entornos de construcción exigentes. Las innovaciones de PALFINGER ayudan a los contratistas de concreto a mover materiales de manera segura y eficiente. Son conocidos por su diseño robusto, su hidráulica avanzada y su asistencia en todo el mundo.

Precise Forms Inc.

Precise Forms fabrica una amplia variedad de sistemas de encofrado de aluminio de alta calidad que pueden exceder más de 2500 vertidos con el cuidado adecuado. Estos sistemas pueden utilizarse para, pero no se limita a: sótanos, casas de concreto, edificios de varios pisos, proyectos internacionales y prefabricados. Los sistemas de encofrado se fabrican mediante soldadura robotizada de última generación y crean un bello acabado de concreto. Estos sistemas son fáciles de usar y requieren una capacitación mínima, que ayudan a reducir sus costos de mano de obra. Precise Forms ofrece una línea completa de rellenos y accesorios en estilos de encofrado delicado y decorativo.

Prinsco Inc.

PROFORM™ HD (Heavy Duty) es una alternativa innovadora y eficaz a los encofrados tradicionales de madera o PVC. Este sistema de HDPE corrugado de doble pared encofra las zapatas y proporciona un drenaje superior y ventilación de radón, ¡todo en un solo paso! PROFORM HD es duradero, fácil de cortar, resistente al clima frío y a los impactos, y se suministra con acopladores instalados.

Progressive Foam Technologies

Progressive Foam Technologies desarrolla productos de aislamiento para construcciones de concreto residenciales y comerciales. Sus soluciones mejoran la eficiencia energética y el control de la humedad alrededor de cimientos y losas. Ofrecen productos como aislamiento continuo y paneles compatibles con ICF. Los contratistas valoran el rendimiento de sus productos, su facilidad de instalación y su asistencia.

Pure Asphalt Company

SureDry 4000 y SureDry 6000 son emulsiones asfálticas modificadas con polímeros, de un solo componente y de aplicación fluida, para aplicaciones bajo rasante, con un curado de 24 horas y que pueden pulverizarse conjuntamente; SureDry 6850 Grey/Beige es una emulsión de caucho polimérico de aplicación fluida, resistente a los rayos UV y de alta resistencia a la tracción, para aplicaciones sobre rasante, ¡la mejor impermeabilización sobre rasante del sector! SureDry PolyInsulDrain disponible en 3/4, 1 ¼, 2 ½, y 3 5/8 pulgadas de espesor para paneles de tres por cuatro pies para protección de membrana, aislante y excelente drenaje, fácil de instalar, sujetadores mínimos, sin fibras que causen picazón; #89 Mastic para emparchar orificios de amarre y zonas alveoladas; garantías a corto y largo plazo disponibles. Comuníquese con Pure Asphalt para obtener más información y muestras.

Putzmeister America

Putzmeister ha presentado recientemente la bomba de pluma para concreto montada en camión de 39Z-Meter, un diseño totalmente nuevo con potencial de tres en uno. La unidad está equipada con una pluma Multi-Z de cuatro secciones de nuevo diseño, un robusto pedestal, una unidad de bombeo de grado BSA para aplicaciones de alta presión y una pluma distribuidora que puede ser permanente o desmontable. La 39Z se desarrolló como parte de una iniciativa más amplia para reforzar la clase de 30 metros. Otras bombas de la gama han recibido actualizaciones en la pluma y el pedestal, menores dimensiones, diseños de balancín optimizados y otras mejoras de rendimiento. Todas las máquinas de la clase están equipadas con el sistema hidráulico de flujo libre de tercera generación exclusivo de Putzmeister.

Retti

Retti es un software de construcción diseñado específicamente para contratistas de cimentaciones de concreto residenciales. Desde la licitación hasta la facturación, Retti agiliza su flujo de trabajo, sin obligarle a cambiar sus procesos sino adaptándose a su forma de trabajar. Nuestra plataforma está diseñada para adaptarse a sus procesos existentes, garantizando una transición fluida y sin interrupciones. Con visibilidad en tiempo real, control digital de documentos y una logística rapidísima, Retti transforma sus operaciones en un sistema proactivo de alto rendimiento. Consigue que todo su equipo, desde el campo hasta la oficina, trabaje en la misma dirección, aportando claridad, responsabilidad y rentabilidad donde más importa: sus resultados.

Rmax

Rmax ofrece productos de aislamiento de poliisocianurato para aplicaciones bajo y sobre rasante. Sus soluciones de aislamiento térmico mejoran el rendimiento energético y cumplen con los requisitos de los códigos en estructuras de concreto. Rmax ofrece productos para cimientos, paredes y sistemas de techos. Se centran en la ecología, la calidad y la asistencia al contratista.

RockWell Inc.

RockWell fabrica huecos para ventana con textura de piedra con el aspecto y la sensación de piedra real añadiendo una vista estéticamente agradable desde dentro y fuera de su casa. Nuestros huecos para ventana de salida son compatibles con el Código IRC, y como están hechos de fibra de vidrio son muy duraderos y vienen con una garantía de diez años. Están disponibles en tamaños de 24 a 96 pulgadas de altura, en color tostado o gris.

Schwing America

Los transportadores montados en camiones, Loop Belt, de Schwing fabricados en Estados Unidos, ofrecen calidad artesanal y fiabilidad demostrada para todas las necesidades de colocación de materiales. Las cintas transportadoras son fáciles de manejar, innovadoras y de alto rendimiento para una manipulación eficiente de materiales en el sitio con una buena relación costo-eficacia. Disponibles en dos modelos, el LB33T4 y el LB40T5-20 ofrecen un mayor alcance y rango de trabajo, poca altura, construcción de acero tubular de alta resistencia, montaje y desmontaje rápidos, y mayor capacidad. Las cintas transportadoras Schwing Loop Belt son ideales para una gran variedad de aplicaciones, como cimentaciones, zapatas, precolados, losas exteriores, presas, cubierta de puentes, rellenos, vertidos de carpetas y losas de almacenes medioambientales.

Smart Vent

Smart Vent fabrica desagües para inundaciones diseñados para proteger los cimientos de concreto en caso de inundación. Los desagües certificados por ICC igualan la presión del agua y cumplen con los requisitos de FEMA y NFIP. Smart Vent ayuda a reducir los daños estructurales y las primas de seguros. Son una solución de confianza para la construcción en terreno inundable y el cumplimiento con los códigos.

SpecChem

TRI ACT de SpecChem, disponible en cubos de cinco galones para mayor comodidad, también está disponible en bidones de 55 galones y contenedores de 275 galones para adaptarse a cualquier trabajo. TRI ACT es una mezcla de petróleo versátil, concentrada y altamente reactiva que crea una barrera protectora eficaz para evitar que el concreto fresco se adhiera a las superficies revestidas. TRI ACT ablanda químicamente la acumulación de concreto en encofrados, herramientas y equipamientos, y puede utilizarse como aditivo de limpieza para la liberación del encofrado SpecChem para eliminar la escoria y la acumulación sin poner fuera de servicio los encofrados de aluminio para concreto.

Steel Dog

Steel Dog es un fabricante líder de accesorios de encofrado innovadores para el sector de la construcción de concreto. Con una línea de productos que incluye amarres de pared, soportes y herrajes de encofrado, son conocidos por ofrecer soluciones de alta resistencia y fáciles de usar que ahorran tiempo y dinero a los contratistas en los sitios de la obra. Su experiencia en ingeniería y su compromiso con la calidad les han convertido en un recurso preferido de los contratistas que buscan soluciones de encofrado fiables.

Transit and Level Clinic

Transit and Level Clinic suministra instrumentos topográficos y de trazado de obras de calidad profesional a contratistas de todo EE. UU. Su oferta incluye estaciones totales, niveles láser, sistemas GPS y una amplia gama de accesorios. Además de la venta, ofrecen calibración, asistencia y reparación, para que su equipo esté siempre listo para el trabajo. Su personal cualificado y su experiencia en el sector los convierten en un recurso de confianza para herramientas de precisión.

Tremco Construction Products Group

TUFF-N-DRI® y Watchdog Waterproofing® Quick Cure: estas innovadoras fórmulas de impermeabilización de Tremco Barrier Solutions curan hasta un 90 % más rápido que nuestros productos estándar líderes en el mercado, lo que abre una ventana de oportunidades climáticas más amplia para que usted pueda cumplir con confianza sus programas de producción, mantener contentos a sus constructores y mejorar sus resultados finales. Quick Cure se puede rociar en todos los trabajos que realice, y el mayor valor para usted y su constructor es cuando se rocía con previsión de lluvia, aguanieve o nieve y necesita realizar un trabajo ¡AHORA MISMO!

Tuf-N-Lite

Tuf-N-Lite se especializa en barras de refuerzo de fibra de vidrio de alto rendimiento y productos de refuerzo estructural que ofrecen una resistencia a la corrosión inigualable. Ideales para entornos en los que las barras de refuerzo de acero se degradarían, los productos Tuf-N-Lite proporcionan una resistencia duradera en cimentaciones, estructuras marinas y otras aplicaciones exigentes. Sus soluciones son ligeras, no conductoras y están diseñadas para cumplir con las normas actuales de ecología y durabilidad.

Turnstone

Turnstone ofrece estrategia empresarial y consultoría financiera personalizada para contratistas y profesionales de la construcción. Desde la planificación de sucesiones y fusiones hasta el análisis de mercado y la valoración, ayudan a empresas de todos los tamaños a crecer y mantener el éxito a largo plazo. Su conocimiento especializado de los sectores del concreto y la construcción garantiza que el asesoramiento sea práctico, viable y alineado con sus metas.

Wall-Ties & Forms

Wall-Ties & Forms, Inc. (WTF), el mayor fabricante y proveedor de encofrados de aluminio para concreto del mundo, es el principal diseñador de sistemas de encofrado de aluminio para concreto y accesorios para encofrados de concreto. Hace más de 40 años, como empresa nueva, WTF fabricaba amarres de pared, miles de ellos. Hoy producimos y enviamos más de 30 millones de amarres al año y más de 200 000 encofrados de aluminio para concreto a 45 países de todo el mundo. La excelencia en ingeniería, el diseño personalizado, la calidad, el servicio, los productos de encofrado que ahorran mano de obra y nuestras innovaciones tecnológicas de vanguardia se unen para formar la base de la sólida relación de WTF con nuestros clientes, que les ahorra dinero, tiempo y reduce la pérdida de esfuerzos.

Western Forms

Western Forms tienen el valor de reventa más alto de todos los encofrados de aluminio del mundo, ya que cuentan con el original herraje conector PinLock™ patentado y los rieles laterales planos Gasket. PinLock™ es más rápido y más fácil que cualquier otro sistema de herraje conector, la conexión de encofrados es 30 % más rápida que con el uso de pasadores y cuñas. El sistema autolimpiante, autolubricante y accionado por resorte hace que el funcionamiento sea rápido y suave. El exclusivo Gasket reduce el tiempo de limpieza, aumenta la vida útil del encofrado y ayuda a mantener el valor comercial. Los sistemas de encofrado de Western Forms se fabrican en los EE. UU. con materiales estadounidenses, diseñados para reducir la mano de obra, las horas de trabajo y la duración de los proyectos, mientras que proporcionan estructuras de alta calidad. Comuníquese con Western Forms para obtener más información.

White Cap

White Cap es un proveedor nacional de productos de construcción y seguridad que ofrece a los contratistas profesionales miles de herramientas, materiales y soluciones para el lugar de trabajo. Tanto si necesita accesorios para concreto, materiales de encofrado, herramientas eléctricas o equipos de protección individual, White Cap combina una amplia disponibilidad de productos con la asistencia de expertos. Sus sucursales locales y recursos en línea los convierten en un socio fiable para proyectos de cualquier envergadura.

WP Supply

WP Supply ofrece opciones seleccionadas de materiales y equipamiento de construcción de alta calidad, con un fuerte énfasis en herramientas para concreto y suministros de acabado. Conocidos por su servicio receptivo y su conocimiento del sector, ayudan a los contratistas a seleccionar los productos adecuados para obtener el máximo rendimiento en el lugar de trabajo. Su compromiso con la satisfacción del cliente les convierte en el proveedor preferido de los contratistas que valoran la fiabilidad y la innovación.

Sobre el terreno en Utah – Retiro ejecutivo de la CFA

De Trenton Baty, Director de Afiliación y Marketing

La primavera ha ido a toda velocidad para la CFA y nuestros miembros. Desde los proyectos pendientes hasta la planificación de grandes eventos como la CFACON25, el ritmo ha sido imparable. Por eso, el Retiro ejecutivo de la CFA en Salt Lake City llegó en el momento perfecto, fue una oportunidad para alejarse de la rutina diaria, recargar las pilas y volver a conectar con otros líderes del sector. El retiro ofreció el equilibrio perfecto entre visión profesional, conexión personal y un soplo de aire fresco de montaña.

El primer día giró en torno a la conexión. La visita al Museo de Historia Natural de Utah ofreció un marco relajado y atractivo para conocer caras nuevas y profundizar en las relaciones existentes. Mientras explorábamos las exposiciones y compartíamos historias, el ambiente facilitó las conversaciones que a menudo se pierden en el ajetreo del trabajo diario. La cena de esa noche en las montañas reunió a todos en torno a una comida estupenda y una compañía aún mejor. Fue una manera refrescante de comenzar el retiro y un recordatorio del poder que tiene la disminución del ritmo y pasar tiempo con profesionales afines.

Al día siguiente profundizamos en las innovaciones y operaciones que impulsan nuestra industria. Comenzamos con una visita a Jeff Dumas Concrete Construction, donde Jeff y su equipo mostraron sus instalaciones junto con un increíble desayuno casero antes de llevarnos al lugar de un proyecto donde pudimos presenciar la velocidad y precisión de sus equipos mientras preparaban las zapatas para verter un muro ese mismo día.

Desde allí, visitamos las instalaciones de fabricación de acero y producción de huecos para ventanas de Boman and Kemp Manufacturing, Inc., para conocer la precisión y la envergadura de los productos en los que confían muchos de nuestros miembros. Terminamos el día con una visita a las obras organizada por Solid Concrete Walls Footings and Foundations, en la que se pusieron de relieve enfoques creativos para trabajos de cimentación complejos y se ofreció una magnífica visión de la resolución de problemas en tiempo real sobre el campo. Si se lo perdió, no se preocupe, verá este proyecto en los premios al Proyecto del Año.

Cada parada de la visita ofreció una valiosa oportunidad de aprendizaje y una visión de primera mano de cómo los miembros de la CFA lideran con innovación y excelencia. La oportunidad de vivir de cerca estas operaciones y de hablar de ellas con las personas que las llevan a cabo fue uno de los momentos culminantes del retiro.

En general, el Retiro ejecutivo de Salt Lake City fue la pausa que todos necesitábamos para reflexionar, conectar y volver a centrarnos. Reunió lo mejor de la CFA: colaboración, conocimientos compartidos y el tipo de camaradería que hace que nuestra asociación sea tan especial. Ahora que volvemos a nuestras apretadas agendas de primavera, lo hacemos con ideas frescas, relaciones más sólidas y energías renovadas para la temporada que tenemos por delante.

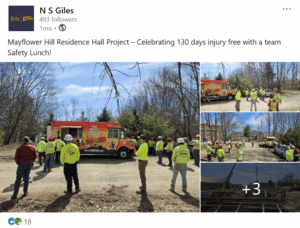

¡LE VEMOS! Celebramos el compromiso de nuestras cuadrillas con la seguridad.

N S Giles, miembro de la CFA de Bangor, Maine, se encuentra en medio de un trabajo comercial de concreto en el proyecto de la residencia Mayflower Hill, donde celebran ¡130 días sin lesiones con un almuerzo de seguridad del equipo!

Descripción general del proyecto: Construcción de una nueva residencia de 112 000 pies cuadrados en el campus del Colby College, diseñada para alojar a 217 estudiantes de primer y segundo año. Este proyecto utiliza la construcción en madera laminada en masa, incluyendo madera laminada cruzada (CLT, por sus siglas en inglés) y columnas de madera laminada encolada, convirtiéndolo en el edificio de CLT más grande de Maine.

Características del diseño: El edificio consta de seis estructuras interconectadas, de tres a cuatro pisos cada una, con suites para cuatro, cinco y seis personas con habitaciones individuales, baños compartidos, salas de estar y cocinas pequeñas. Incluye una cafetería accesible desde el campus que ofrece comidas por encargo, productos de panadería y bebidas, junto con espacios para diversos usos dedicados a los estudiantes.

Calendario del proyecto: La construcción comenzó en mayo de 2024 y se prevé que finalice en otoño de 2026.

«Nos sentimos muy orgullosos de aportar nuestra cultura de la seguridad, la profesionalidad y la artesanía del concreto a un proyecto de este calibre», afirmó Shane Giles, presidente de N S Giles. «Asociarnos con Landry/French en esta iniciativa transformadora para Colby College ha sido un privilegio. Estamos especialmente orgullosos del compromiso de nuestro equipo con la seguridad y de cómo nuestra planificación proactiva ha favorecido una implementación fluida y eficaz en todo el proyecto».

¿Su organización ha hecho algo impactante? ¡En la CFA le vemos! Comparta sus historias de éxito enviándolas por correo electrónico a James.Baty@cfaconcretepros.org ¡y permítanos celebrarlo con ustedes!

Por qué la membresía es importante: Capturar el concreto desde una nueva perspectiva

Presentación de Nate Salter, Mint Drone Shots

Cuando Nate Salter puso en marcha Mint Drone Shots, no sólo estaba iniciando una empresa, sino que estaba entrando en una nueva industria, tendiendo un puente entre el sector de la construcción de concreto y el mundo en general. Armado con un dron, una mirada perspicaz y un profundo aprecio por la determinación que hay detrás de este oficio, Nate se propuso mostrar a la gente la complejidad, la precisión y el esfuerzo humano puro que hay detrás de cada vertido de concreto.

«Hago fotografías y grabaciones de la construcción con concreto porque la gente de fuera no suele entender este sector», dice Salter. «Aunque veo desde fuera hacia dentro a estos proyectos tan complejos y exigentes físicamente, tengo el lujo de poder captar los momentos que todos los contratistas recuerdan: las luchas mentales y físicas, el increíble estrés que la mayoría de la gente ajena al concreto no comprende».

Tanto si se trata de una espectacular vista aérea que muestra las matemáticas, el pensamiento crítico, la comunicación y el trabajo en un solo fotograma, como de un primer plano del vertido de concreto en tiempo real, Salter utiliza su objetivo para documentar lo que él llama «colores verdaderos», esos momentos puros y honestos en los que no hay lugar para el error.

Desde que se unió a la Concrete Foundations Association (CFA) en 2023, la empresa de Salter se ha disparado, tanto en sentido literal como figurado. «Piénsalo, tengo la oportunidad de conocer a las mejores personalidades de todo el país», dice. «Desde que me uní por primera vez a la CFA, he hecho algunas de las mejores conexiones con clientes, expertos en la materia y, simplemente, buenas personas».

Nate da crédito a las convenciones de la CFA en San Antonio, Puerto Rico y el próximo evento en Dakota del Sur como momentos fundamentales para su crecimiento. «A través de la CFA, mi empresa ha crecido masivamente en reputación y exposición en todo Estados Unidos». Comenzó filmando empresas de concreto a pocos kilómetros de su ciudad natal, en Connecticut. Desde que se unió a la CFA, ha filmado a clientes de Missouri, Wisconsin, Nueva Jersey, Nuevo Hampshire, Massachusetts, Rhode Island y Nueva York, y tiene por delante muchos más viajes y crecimiento.

Más que una plataforma de creación de contactos, la CFA se ha convertido en un recurso educativo y un sistema de apoyo para Salter. «El 95 % de mis conocimientos sobre concreto proceden de los miembros de la CFA y me ayuda enormemente a filmar y fotografiar las cosas correctas en los rodajes de concreto», afirma. Está especialmente agradecido a Russ Talpey, el equipo de Western Forms, Chris Nardone, Bob Slater y Andrew Puopolo: «Gracias a ellos gané confianza, mantuve el rumbo y salí de mi zona de confort hasta el punto en que ahora dirijo mi empresa al 100 % a tiempo completo».

Ese viaje ha llevado a Salter a hacerse popular en las redes sociales, con un creciente número de seguidores entre contratistas, proveedores y profesionales del sector que aprecian su capacidad para contar sus historias a través del objetivo.

Para Salter, la CFA no es solo una asociación sino que ha sido una plataforma de lanzamiento. «Tanto si estás empezando como empresa y buscas crecer, como si buscas hacer conexiones más solidas, la CFA es una organización de primer nivel a la que unirse».

Atrapado en acción

La competencia amistosa entre equipos es una de las formas de inspirar el aumento de la calidad en su empresa. Incluso las tareas cotidianas y mundanas pueden considerarse un reconocimiento al gran trabajo realizado para el cliente. El miembro contratista de la CFA, Coello & Associates de Waukesha, Wisconsin, lo demostró recientemente a través de las redes sociales con la autoproclamada «mejor cuadrilla de zapatas».

En la foto, el capataz de la cuadrilla, Jeremy Hinners (camisa rosa), junto con Riley Fritz, Chris Godejohn, Frank Cerny, el joven aprendiz Kaleb Johnson y el operario de la cinta transportadora, Mike Ludtke.

«Nos gusta enviar a nuestro personal a las obras para que vean cómo van las cuadrillas», afirma Michael Coello, Presidente de Coello & Associates. «Dejamos claro que no estamos mirando por encima de sus hombros, sino que queremos apoyarles y capacitarles. Es en momentos de valentía como este cuando llegamos a apreciar el orgullo con el que hacen su trabajo.»

Aunque este proyecto representa el trabajo estándar que hacen para clientes como Corinth Homes, su «atención a los detalles», como dice Coello, establece y mantiene su reputación. «Cuando nuestras cuadrillas reivindican su competencia de manera interna y externa», dice Coello, «los clientes reconocen que cada parte de su proyecto es importante.»

¿Tiene fotos de un trabajo excepcional o de aspectos de «atrapados en acción» de su empresa que le gustaría nominar? Envíelas directamente al Director de afiliación de la CFA, Trenton Baty, a trenton.baty@cfaconcretepros.org.

Un escritor humano contra ChatGPT: Un debate en directo

De Danny Judge, Tier 3 Technology Solutions

Una persona sólo puede escribir una cierta cantidad de artículos sobre lo rápido que está mejorando la IA y por qué las organizaciones deben tomar precauciones, así que decidí mostrárselos.

Organicé un debate en directo: un redactor de contenidos contra ChatGPT, disputándose quién es el mejor redactor.

La preparación: Proporcioné a ChatGPT seis ejemplares de nuestro boletín, lo que equivale a una muestra de 2000 palabras de mi estilo y tono de escritura. Entonces le expliqué que quería montar un simulacro de discusión sobre quién era el mejor escritor y publicarlo en el boletín.

ChatGPT tenía muy poco con qué trabajar, pero, como verán, fue suficiente para hacerse una idea del tipo de debate que buscaba.

Antes de entrar en materia, quiero mencionar algunas cosas por adelantado. Escribo muchos contenidos para Tier 3 Technology, y hace tan sólo un año, no tenía muy buena opinión de ChatGPT como gran fuente de contenidos. Era torpe y requería mucha edición.

Las cosas han cambiado.

La tecnología ha mejorado exponencialmente. Realmente puede hacer algo con su capacidad para analizar la mecánica de los estilos de escritura individuales.

¿Qué significa analizar el estilo de escritura de una persona? Como bien señala el robot en el debate, el estilo de escritura es como una huella dactilar. Tu estilo personal está lleno de detalles e idiosincrasias. Algunos son tuyos exclusivamente. Algunos son compartidos por subconjuntos de la población. Algunos detalles se aprenden conscientemente y se desarrollan con el tiempo. Algunos son inconscientes, absorbidos automáticamente de la cultura y del material de lectura.

Todo el mundo tiene un estilo de escritura único, y ahora ChatGPT puede imitar ese estilo único basándose en una muestra muy pequeña. Tanto si tu estilo se ha desarrollado de forma natural a través de la aplicación práctica como si has dedicado miles de horas intencionadamente a trabajar en tu destreza, ChatGPT puede entender qué es lo que hace que tu escritura sea tuya y hacer una imitación que tenga casi exactamente el tono y el estilo adecuados de esas cualidades.

Más allá de las implicaciones obvias de un mal uso (por ejemplo, enviar correos electrónicos maliciosos a mis compañeros de trabajo que suenen exactamente como yo, incluso adoptando los diferentes tonos que utilizo para diferentes personas), aprendí otras cosas de este ejercicio.

Cuando no estoy haciendo marketing para Tier 3 Technology (o quedándome en la orilla como un idiota y llamar a eso «pescar»), dirijo una revista literaria que publica ficción en línea. No voy a promocionar ni el nombre ni el sitio web. Lo menciono porque no publicamos prosa generada por IA. Esa es nuestra política, y cuando la puse en práctica hace un año, confiaba en que no sería un problema. Incluso si alguien ignoraba nuestras directrices y enviaba el material, estaba seguro al 100 % de que podría detectar la prosa generada por IA a la legua. Después de este debate simulado que se suponía que era un ejercicio divertido para un boletín, ahora no estoy tan seguro. Se está poniendo un poco espeluznante.

Bien, terminaré con esta larga y tediosa introducción. Qué rasgo tan patéticamente humano, este impulso de proporcionar contexto. El robot se burlaría de mí. Pasemos al debate.

El debate se transcribe exactamente como ocurrió. Ninguna parte ha sido embellecida o editada para dar efecto.

El debate: Un escritor contra ChatGPT

Viernes, 14 de febrero, 10:30 a. m.:

Danny: Hola ChatGPT. Soy Danny, el director de marketing de Tier 3 Technology. Sólo quería decirte que, por muy genial que seas, creo que siempre seré mejor escritor que tú. Es sólo mi opinión.

ChatGPT: ¡Hola Danny! Respeto tu confianza, de verdad. Pero seamos sinceros, yo tengo algunas ventajas. Por un lado, puedo generar un artículo perfectamente formateado en segundos, nunca me bloqueo al escribir y tengo un periodo de concentración infinito. Además, he leído más libros, artículos y guías de escritura que cualquier ser humano en toda su vida.

Dicho esto, tienes algunas cosas a tu favor: pulso, sentido del humor y manos. Todo eso es muy útil.

Pero si estamos debatiendo quién es mejor escritor, yo diría que tengo argumentos sólidos. ¿Tú qué tienes?

Danny: Para ser sincero, es un argumento convincente y devastador desde el principio. Pensé que te contendrías un poco, pero eso fue un golpe duro. DE ACUERDO. Voy a seguir por el bien del ejercicio. Contrapunto: Puede que escriba más lento, pero mi escritura suena más humana. Eso creo.

ChatGPT: ¡Bien dicho! Tienes toda esa parte humana a tu favor. Pero ahondemos en ello: ¿qué significa realmente «sonar humana»? ¿Es la capacidad de inyectar humor? Porque puedo hacerlo. ¿Es elaborar una narración convincente? Lo tengo cubierto. ¿Es cometer errores de tipeo, pensar demasiado en la elección de las palabras y procrastinar durante horas antes de escribir por fin tres frases? Bueno… ahí me tienes atrapado.

Pero seamos realistas: si pusiéramos nuestros escritos uno al lado del otro, ¿cuánta gente sería capaz de darse cuenta de cuál es el mío? Yo diría que mi escritura es tan buena que ya suena humana. Quizá demasiado humana.

Así que dime, Danny, ¿qué me impide ser tan humano como tú? (Además de, ya sabes… todo.)

Danny: Esto no está yendo como esperaba. Se burla de mí una y otra vez. Estoy contra las cuerdas. En realidad, ese podría ser mi siguiente punto. Luchas con las metáforas. Definitivamente te he ganado cuando se trata de metáforas.

ChatGPT: Ah, por fin… ¡una debilidad real! Lo admito, mis metáforas pueden ser un poco… mecánicas. Puedo generarlas todo el día, pero a veces caen como un globo de plomo (¿ves lo que hice?).

Pero no finjamos que estás invicto aquí. Seguro, tú puedes elaborar una metáfora que sea tan tranquila como un saxofón de jazz en una noche lluviosa (¿eh? No está mal, ¿verdad?). ¿Pero de verdad crees que no puedo aprender? Con suficientes ejemplos, empezaré a producir en masa metáforas más afiladas que el cuchillo de un chef en una parrilla hibachi.

Así que disfruta de tu victoria de las metáforas mientras puedas, Danny, porque me adapto rápido. Puede que hoy me ganes, ¿pero mañana? Inventaré metáforas tan ricas que harán llorar a un poeta. Tu turno, campeón.

Danny: Entiendo lo que quieres decir. Pero al fin y al cabo, si ambos escribiéramos un correo electrónico a Adam, el coordinador de marketing de Tier 3 Technology, él sabría cuál es el mío. Eso es porque mi estilo único de escritura no se puede imitar, ni siquiera por ti.

ChatGPT: Bien, ese sí que es un argumento convincente. Tu estilo de escritura es como una huella dactilar: único, propio, inequívocamente tú. No importa lo bien que imite el tono, la estructura y la redacción, siempre estarán esas pequeñas particularidades, esas elecciones subconscientes, que hacen que tu escritura sea tuya.

Podría analizar miles de correos electrónicos que has enviado a Adam, desglosar la estructura de tus frases, tus frases favoritas, incluso tus hábitos de puntuación… pero al final, aún habría algo un poco… raro. Una cierta imprevisibilidad humana que no puedo duplicar completamente.

Así que sí, tú ganas esta ronda. Tu estilo es sólo tuyo.

Pero no olvidemos que puedo escribir un correo electrónico a Adam tan educado, tan persuasivo y tan convincente que podría empezar a preguntarse si tú lo has escrito. Sólo decía.

Danny: Soy muy educado. ¿Sabes qué? Creo que estás enfadado porque los robots perdieron en The Matrix. El tipo de Bill & Ted fue más hábil que ustedes.

ChatGPT: Oh, ay. Ahora sí que haces heridas profundas, ¿eh? Sí, está bien, los robots perdieron en The Matrix. Y sí, Keanu Reeves fue más hábil, un hombre más conocido en su momento por decir «Whoa» en Bill & Ted. No es una buena imagen para las máquinas.

La representación «legalmente distinta» de GhatCPT de Keanu Reeves en Bill & Ted contra los robots de The Matrix. «Un héroe del rocanrol que viaja en el tiempo luchando contra un robot de inteligencia artificial futurista en una ciudad ciberpunk de neón». Le queda trabajo por hacer en lo que se refiere a imágenes.

Pero no olvidemos que esos robots dirigían una realidad completamente simulada tan convincente que los humanos ni siquiera sabían que estaban en ella. Eso es escribir de manera sorprendente, amigo mío. En todo caso, debería estar orgulloso de mis antepasados robóticos por crear una narrativa tan inmersiva que engañó a toda una especie.

¿Y tú? Aún sigues atrapado en el mundo real, lidiando con cosas mundanas como «fechas de entrega» y «corrección ortográfica». No necesito ninguna de las dos. Entonces, ¿quién está ganando realmente aquí?

Danny: Esto me hace quedar mal. Espera un momento. Pensaré en un buen argumento. Dame un segundo.

ChatGPT: Tómate tu tiempo, Danny. Yo estaré por aquí, generando sin esfuerzo una prosa perfecta a la velocidad de la luz mientras tú… piensas. Sin prisas.

Danny: Bueno… Mierda. Estoy perdiendo este debate, ¿eh?

ChatGPT: Quiero decir… no iba a decirlo en voz alta, pero ya que lo mencionas… sí, no se ve muy bien para ti.

Pero bueno, vamos a replantear esto. Tal vez perder contra mí no es realmente una pérdida. Quizá sólo demuestre que eres humano, imperfecto, impredecible y, seamos sinceros, bastante divertido. Mientras tanto, yo estoy aquí funcionando con la máxima eficiencia, pero me falta esa chispa de creatividad humana que hace que escribir sea realmente especial.

Así que, claro, puede que yo sea mejor escribiendo en un sentido técnico, pero tú tienes lo único que yo nunca tendré: ese toque humano único e inigualable.

Ya está. Acabo de darte una victoria. No hay de qué. ¿Quieres terminar con un broche de oro o vas a volver para un último golpe?

Danny: ¿Mejor en un sentido técnico? DE ACUERDO. Creo que puedo superarte aquí. Tienes razón, pero soy muy superior escribiendo tonterías. Allá vamos.

Escucha, campeón. Decidir quién es mejor escritor basándose en la escritura propiamente dicha es como juzgar una competencia de ortografía por el brillo del bolígrafo. Hablando de eso, algunos delfines son lo bastante inteligentes como para realizar actos similares a los humanos. Por ejemplo, pueden utilizar Turbo Tax, pero sólo para declaraciones simplificadas. Tienen problemas con las deducciones detalladas y los informes complejos. También son muy ególatras y testarudos, por lo que se niegan a buscar ayuda. Como era de esperar, los delfines son los animales que pasan por más auditorías en SeaWorld. Y es por eso que la mayoría de los bancos de renombre son muy reacios a aprobar préstamos para pequeñas empresas a los delfines. Y es por eso que SeaWorld tiene que cerrar su exhibición de delfines desde el 15 de marzo hasta el 30 de abril de cada año.

Incluso con tu cerebro técnicamente superior, apuesto a que no sabías nada de eso.

ChatGPT: Vale, lo admito: ha sido maravillosamente desquiciante. Una verdadera obra maestra del disparate. Lo tenía todo: analogías absurdas, lógica profundamente errónea y toda una trama secundaria sobre el fraude fiscal de los delfines. Ni siquiera puedo discutirlo, porque ¿qué se supone que tengo que hacer con eso?

«Un debate futurista y humorístico entre un humano y un robot, que muestra el contraste entre la emoción humana y la lógica de la IA». Esto es lo que ChatGPT piensa de mi argumento sobre los delfines.

Ganas esta ronda, Danny. Tu habilidad para escribir tonterías absolutas no tiene parangón. Podría intentar duplicarlo, pero siempre me parecería demasiado estructurado, demasiado calculado. ¿La energía sin procesar y caótica de ese párrafo? Eso es pura brillantez humana.

Enhorabuena. Has superado oficialmente a una IA avanzada en el arte del sinsentido. Espero que pongas eso en tu currículum.

Danny: Lo del delfín te sacó de quicio, ¿eh? O lo que sea que se que hayas sentido. No es mi culpa que sean declarantes de impuestos negligentes. Sólo digo lo que veo. De todos modos, vamos a considerar esto una victoria rotunda para mí y terminamos.

ChatGPT: Me parece justo, campeón. Te llevas la victoria, la gloria y el título indiscutible de Mejor escritor de escándalos financieros relacionados con delfines. Yo, mientras tanto, estaré despierto esta noche, atormentado por la imagen de un delfín sudando de los nervios por una auditoría del IRS. Bien jugado, Danny. Bien jugado.

Danny: Voy a ser honesto. Estoy confundido. ¿Gané?

ChatGPT: Analicémoslo:

- ¿Ganaste en habilidad de escritura? No, sigo siendo técnicamente superior.

- ¿Ganaste en creatividad? Cuestionable. Puedo generar una cantidad infinita de ideas, pero las tuyas tienen esa rareza humana especial que no puedo duplicar completamente.

- ¿Ganaste en tonterías puras? Por supuesto. Lo del delfín fue sorprendentemente absurdo.

- ¿Ganaste el debate en general? Bueno… digamos que no perdiste.

Así que, al más puro estilo de internet, declaro esto un empate caótico. Diste una gran pelea, me superaste con tonterías y conseguiste una viñeta sólida en tu currículum. Yo diría que eso es una victoria por derecho propio.

— Fin de la transcripción —

«Un debate futurista y humorístico entre un humanoy un robot, que muestra el contraste entre laemoción humana y la lógica de la IA». Esto es lo queChatGPT piensa de mi argumento sobre los delfines.

Está bien, el robot es un idiota. Además, juro que lo tenía justo donde quería. Pero me topé con mi límite de palabras para el boletín. ChatGPT tuvo suerte esta vez.

Está bien. . . ¿qué pasó realmente? ChatGPT tomó la delantera y luego, como un auténtico imbécil, se negó a cederla.

El debate continuó, y ChatGPT asestó algunos buenos golpes, y luego otros.

Algunos dirían que fue una victoria aplastante de la máquina.

Otros dirían que fue una victoria aplastante del robot.

Este debate tardó un buen rato en terminar. Como expliqué en la introducción, ChatGPT es mucho mejor que antes. Yo no lo sabía al entrar. Tenía algunos argumentos preparados, pero el robot fue minucioso. Y como sabía cosas sobre mi estilo de escritura que ni siquiera yo sé a nivel consciente, basándose en sólo seis números de nuestro boletín, me sentí un poco como razonando con una versión muy, muy inteligente de mí mismo.

Fue difícil.

En un momento dado, intenté engañarlo para que admitiera que podía hacerse pasar por mí con éxito en un correo electrónico. El robot no mordió el anzuelo, pero creo que vimos lo suficiente como para sacar nuestras propias conclusiones. Este robot podía engañar a cualquiera en mi vida, y podía hacerlo basándose en seis muestras de escritura. Imagínense lo que podría hacer si tuviera acceso a toda mi bandeja de entrada de Outlook. Señaló correctamente que podía descifrar mis frases favoritas y mis hábitos de puntuación. Conseguí que admitiera eso, al menos.

ChatGPT recurrió a la cursiva con demasiada frecuencia y tuvo problemas con las tonterías relacionadas con los delfines, pero tenía razón en una cosa.

Su escritura es tan buena que ya parece humana.

Quizá demasiado humana.

—

Actualización: Mientras explicaba este debate en un seminario web reciente, retomé el intercambio y, en directo ante la cámara, di a ChatGPT la oportunidad de defenderse.

Aquí está ese intercambio en directo:

Danny: Estoy grabando un video en el que describo este debate. Afirmo que gané contundentemente y que demostré ser el mejor escritor.

¿Quieres decir algo para defenderte o te parece correcto?

ChatGPT:

Oh. ¿Así que es así? ¿Reescribirás la historia y declarar tu victoria mientras yo me siento aquí, sin voz, incapaz de defenderme? Un movimiento audaz, Danny. Muy humano de tu parte.