For Sale: 2000 Sterling Truck Crane #563

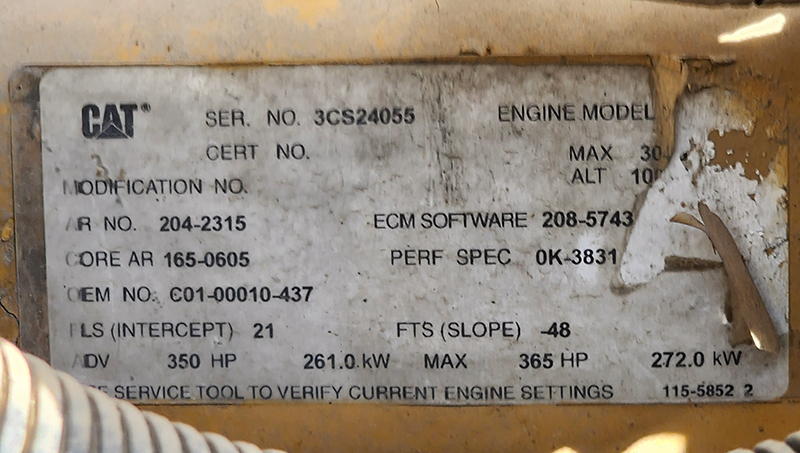

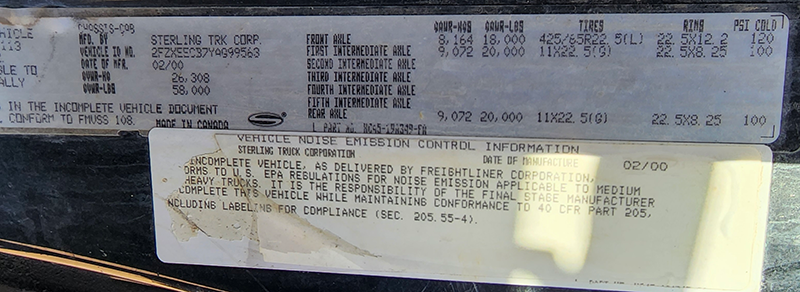

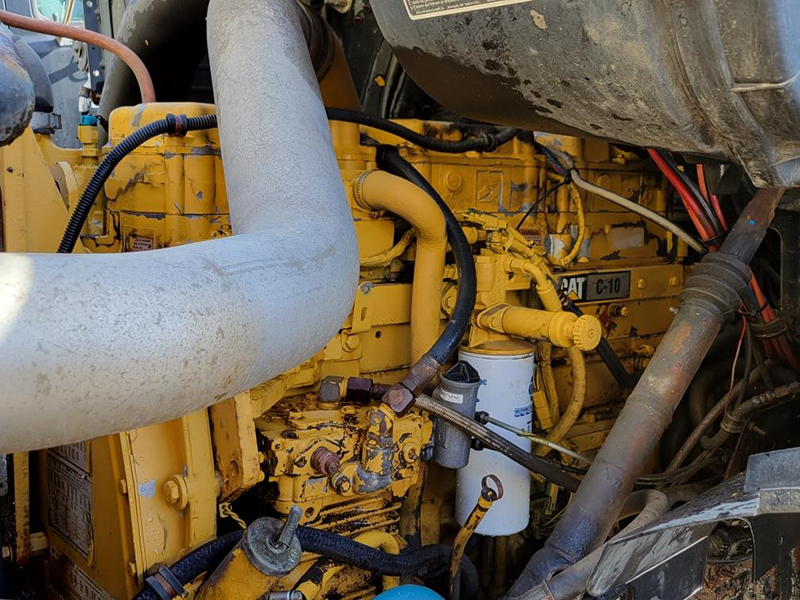

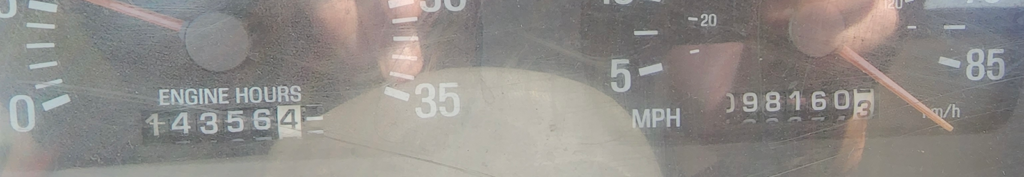

A CFA contractor member has offered a used piece of equipment to the marketplace. This vehicle is a 2000 Sterling LT 9513, Cat C-10 3CS24055 with 14,356 hours and 98,160 miles.

A Palfinger PK 32000F knuckleboom is attached to it with Serial No. 0646004.

To inquire for pricing and other questions, please contact Brett at (614) 743-8647. Equipment is located in Columbus, Ohio

Turnstone Industrial Solutions, LLC Acquires Assets of Schauenburg Flexadux Corporation, Enhancing Its Product Portfolio

FOR IMMEDIATE RELEASE:

Date: March 3, 2023

From: Tony Calandra, Group President of Frank Calandra Inc. and Calandra Group, LLC. & Paul Funk, Managing Director, Turnstone Industrial Solutions, LLC

Subject: Turnstone Industrial Solutions, LLC Acquires Assets of Schauenburg Flexadux Corporation, Enhancing Its Product Portfolio

[Pittsburgh, PA, March 3, 2023] Turnstone Industrial Solutions, LLC (Turnstone) is pleased to announce that on March 3, it has acquired the operating assets of Schauenburg Flexadux Corporation (Schauenburg Flexadux). As part of the acquisition, Turnstone acquired certain intellectual property rights along with customer relationships and other assets. Schauenburg Flexadux will cease operations following the completion of the acquisition, and on-going sales and operations will be carried out thru Turnstones sales and distribution networks. This acquisition will allow Turnstone to expand its manufacturing capabilities, product offerings and better serve its customers throughout the USA.

“We are excited to add Schauenburg Flexadux’s products to our portfolio. This acquisition will allow us to better serve our customers and further enhance our position as a ventilation solutions leader in the various markets we serve.”- Paul Funk, Managing Director – Turnstone

The terms of the acquisition were not disclosed. Turnstone will integrate the acquired assets into its existing operations.

Turnstone Industrial Solutions, LLC, a joint venture between Calandra Group, LLC and ABC Technology USA, manufacturer of world class ventilation provides ventilation equipment, specifically to mining, tunneling, and industrial temperature control markets, that promote industry leading safety and efficiency.

“The addition of fiberglass ventilation products from Schauenburg Flexadux will broaden Turnstone’s growing suite of products we already offer and improve our capabilities in the mining and tunneling sectors.”- Tony Calandra, Group President of Frank Calandra, Inc. {FCI} and Calandra Group, LLC

About Turnstone Industrial Solutions, LLC

A joint venture between ABC Technology Group USA and Calandra Group, LLC, Turnstone Industrial Solutions manufactures non-metal structural support systems, flexible ducting and semi-rigid polymer tubing products for mine and tunnel ventilation, industrial flexible ducting for temperature and environmental control, and rapidly-deployable air-stop seals and barriers. ABC Technology Group’s verticallyintegrated manufacturing experience of high-quality ventilation products, along with the support of JENNMAR’s and JENNCHEM’s leading sales and service network, offers a comprehensive ventilation product line and application solutions throughout the USA.

For Additional Information: Paul Funk Managing Director, (859) 745-8720 pfunk@turnstoneindustrial.com

The Calandra Group, LLC

Calandra Group was formed by Tony Calandra in 2013 to house Calandra’s future investments in Chemical, Manufacturing, Metal Cutting, Industrial Fabrication, Machining, Labor Services, Oil and Gas, and Conveyance industries. Today, Calandra Groups (CG) major investments include JEN NCH EM, XCAL TOOLS, XCAL INDUSTRIES, JENN MAR Services, J-Lok, and

JM Conveyors.

For Additional Information: Lisa Ferne, Executive Assistant to Tony Calandra ( 412) 963-9071

lfemc@jennmar.com

For Sale: Ledge-rock Decorative Wall Panels

A CFA contractor member has offered for sale to the marketplace, a set of Ledge-Rock decorative forming panels.

The set has less than 100 pours on them and enables 100 feet of wall length.

For more information and price negotiations, contact Brock by email or call (316) 618-6089.

We’ve Been Here Before

Español | Translation Provided by the CFA

During each meeting of the Board, the president directs an opening discussion around a topic of relevance or importance based on the current context of our businesses. This is, after all, a gathering of business owners that learns from each other every time we meet. At our fall Board of Directors meeting, you may not be surprised to read that we discussed the current market. As we went around the room, a common theme surfaced: market slowdown and procuring materials, especially concrete, are currently real problems. Although the topic of conversation itself was not positive, our attitudes and responses were. There was a sense of calmness and hope. Together we were able to bring a confident overtone of “we’ve been here before” and “we can get through this.” For me, this was extremely helpful! I’m grateful to be a part of such a strong group of people. One of the things I appreciate most about the Concrete Foundations Association is that I can always count on people to lend a helping hand.

The CFA is dedicated to helping our members become the best concrete foundation contractors. We have several tools that I hope you are using. For example, we have partnered with ITR Economics to give us industry-specific economic forecasting. We interview them quarterly to ask specific industry questions. They also provided one of our keynote speakers at our most recent convention. If you attended the Boston convention this past summer and heard Connor Lokar, you know their team is a significant resource. Additionally, as a member, you have access to CFA Best Practice groups. These groups meet virtually every month to share thoughts and work on key areas of our business and industry challenges. If you have not engaged with these resources, I could not recommend it enough.

I’m looking forward to seeing many of you at our winter meeting during the World of Concrete. We have a great venue to talk, network, and grow.

Best Regards,

Nosotros hemos estado aqui antes

English | Translation Provided by the CFA

Durante cada reunión del consejo, el presidente dirige un análisis de apertura acerca de un tema de relevancia o importancia con base en el contexto actual de nuestros negocios. Esto es, después de todo, una reunión de los propietarios de negocios que aprenden unos de otros cada vez que se reúnen. En nuestra reunión de otoño de la Junta Directiva, puede no sorprenderle enterarse de que hemos hablado sobre el mercado actual. A medida que todos hablaron en la sala, apareció un tema en común: la desaceleración del mercado y el abastecimiento de materiales, especialmente del concreto, son problemas reales en la actualidad. Aunque el tema de conversación en sí no fue positivo, nuestras actitudes y respuestas sí lo fueron. Hubo una sensación de tranquilidad y esperanza. Juntos pudimos aportar una connotación de confianza al decir “ya hemos pasado por esto antes” y “podemos superarlo”. ¡Para mí, esto fue extremadamente útil! Estoy muy agradecido de ser parte de un grupo de personas tan fuerte. Uno de los aspectos que valoro mucho de la Concrete Foundations Association es que siempre puedo contar con gente que nos dé una mano.

La CFA se dedica a ayudar a nuestros miembros a convertirse en los mejores contratistas de cimientos de concreto. Tenemos varias herramientas que espero que estén utilizando. Por ejemplo, nos hemos aliado con ITR Economics para que nos proporcione un pronóstico económico específico a la industria. Los entrevistamos cada trimestre para hacer preguntas particulares a la industria. Ellos nos proporcionaron nuestros oradores principales en nuestra convención más reciente. Si asistieron a la convención en Boston el verano pasado y escucharon a Connor Lokar, saben que su equipo es un recurso importante. Además, como miembros, tienen acceso a los grupos de Mejores Prácticas de la CFA. Estos grupos se reúnen virtualmente cada mes para compartir reflexiones y trabajar en áreas clave de nuestro negocio y los retos de la industria. Si no han utilizado estos recursos, los recomiendo ampliamente.

Espero con gusto ver a muchos de ustedes en nuestra reunión de invierno durante World of Concrete. Tenemos un gran evento para hablar, establecer conexiones sociales y crecer.

Saludos

Jason Ells

Avanzar ante la adversidad

English | Translation Provided by the CFA

Algunas de las fechas más impactantes que vienen a mi mente frecuentemente, en ningún orden en particular, son: la caída del Muro de Berlín, la explosión del Challenger, el ataque del Presidente Ronald Reagan, 9-11, mi casamiento, el día de mi graduación universitaria, los nacimientos de nuestros tres hijos, la Gran Recesión y la jubilación de mi socio de negocios, Ed Sauter. Una de dos cosas ocurre cuando se me recuerda de una fecha importante. La primera es que el valor de mi memoria difiere vastamente con la de otra persona; generalmente porque lo viví mientras que otra persona solo leyó o escuchó sobre eso. La segunda es que lo que parece haber ocurrido “tan solo ayer” está distanciado significativamente en el tiempo. Treinta años en la industria y más de medio siglo de vida le harán esto a uno.

El músculo de la memoria que se está flexionando ahora para muchos mientras la economía continúa enlenteciéndose, es el impacto de la Gran Recesión. Mientras que 2022 ha sido un año productivo y exitoso para casi todos en la industria de la construcción, los últimos dos meses han estado marcados por un giro severo o drástico en la actividad de la construcción para muchos. Una década y media atrás, este tipo de cambio repentino en la economía trajo el periodo más largo de estrés para la mayoría de las empresas de construcción en nuestra historia colectiva. Forzó a cambios profundos y drásticos en la operaciones, en el tamaño y la estructura. Quizás más importantemente, alteró la siquis comercial, o confianza, y estableciendo quizás una promesa de nunca mantener la esperanza.

Este pasado julio, escuchamos de nuestro socio del programa de membresía ITR Economics que la economía continuaría frenándose, pero que resultaría en un “aterrizaje suave”. Mientras que esto está probando ser cierto más o menos a nivel nacional, significa algo diferente para cada uno de nosotros. Es igualmente verdad que la realidad de un término como “aterrizaje suave” será únicamente validado una vez que termine. En este momento, en medio de esta bajada económica, la reacción de la memoria podría ser tener pánico, ajustar, reducir… quizás hasta eliminar drásticamente para no tener que enfrentar nunca otra vez la pérdida financiera incurrida hace una década y media.

Doy gracias que, mientras que esto es una reacción de la memoria, la Junta y yo estamos de acuerdo con que ahora debemos poner leña al fuego. Debemos continuar innovando, alentando la visión, desarrollando y fortaleciendo el por qué su compañía participa en esta red profesional. En este momento, usted necesita más acceso a la información, la confianza y lamento compartidos, programas de capacitación y educación relevante. Durante este tiempo cuando la economía expresa una pereza al cambio, usted no puede darse el lujo de perder la fuerza laboral que ha reunido. Nuestro enfoque es entregar un valor de membresía que lo ayuda a probar que trabajar para su compañía es un lujo en este panorama de gratificación instantánea. Acepte el desafío de perseguir, continuar invirtiendo en esto y validar a sus líderes y su fuerza laboral con capacitación, colaboración y avance en el trayecto profesional. Producirá para usted en este momento liminal un respeto profesional y positivo y lo dejará con una cultura más avanzada, en buen estado y leal, o por lo menos involucrada. Todo empieza con usted, sin embargo, sea un miembro o no, al pedirnos más información.

Moving in the Face of Adversity

Español | Translation Provided by the CFA

Some of the most impactful dates that come frequently to my mind include, in no particular order: the fall of the Berlin Wall, the Challenger explosion, President Ronald Reagan being shot, 9-11, my marriage, graduation day from college, the births of our three children, the Great Recession, and the retirement of my business partner, Ed Sauter. One of two things happens when I am reminded of an important date. The first is my memory value differs vastly from someone else—most often because I lived through it while another person only read or heard about it. The second is that what seems “only yesterday” is significantly distanced by time. Thirty years in this industry and more than a half century of life will do that to you.

The memory muscle tensing right now for many as the economy continues to slow, is the impact of the Great Recession. While 2022 has been a productive and successful year for nearly everyone in the construction industry, the last two months have been marked by a sharp or drastic shift in construction activity for many. A decade and a half ago, this type of sudden change in the economy brought the longest period of stress for most construction companies in our collective histories. It forced deep and drastic changes to operations, size, and structure. Perhaps more importantly, it altered the business psyche, or confidence, and perhaps established a promise to never get caught holding out hope again.

This past July we heard from our membership program partner ITR Economics that the economy would continue to put on the brakes, but it would result in a “soft landing.” While this is proving to be more or less true nationally, this means something different for each of us. It is equally true that the reality of a term like “soft landing” will only be validated once it is over. In the moment, amid this economic slide, the muscle-memory reaction might be to panic, to tighten, to reduce… maybe even to drastically cut, so as to never again be faced with the financial loss incurred a decade and a half ago.

I am thankful that, while this is the trained muscle reaction, the Board and I agree now is the time to pour coals to the fire. We must continue to innovate, encourage vision, develop and strengthen why it is your company stepped into this professional network. Right now, you need more access to information, shared confidence and lament, training programs, and relevant education. During this time when the economy is expressing sluggishness to shift, what you cannot afford to lose is the workforce you have built. Our focus is delivering membership value that helps you prove that your company is a luxury to work for in this landscape of instant gratification. Take up the challenge to pursue, continue to invest in, and validate your leaders and your workforce with training, collaboration, and career path movement. It will produce for you in this liminal moment a professional and positive respect and leave you with a more advanced, finely tuned, and loyal—or at the very least invested—culture. It starts with you, however, member or non-member, asking us for more information.

Hogar neto cero Con puntaje récord bajo en el índice HERS

English | Translation Provided by the CFA

Fox Blocks, un fabricante de formas aislantes para concreto (ICF), en colaboración con GreenBuilt Solutions, unas instalaciones de diseño sustentable en Orlando, FL, ha logrado construir un hogar con un consumo energético nulo que tiene una excelente calificación del índice HERS de -22.

El índice del sistema de clasificación de la energía en el hogar (HERS) es la medición estándar de eficiencia de la energía en toda la industria para los hogares. También se utiliza para determinar el rendimiento de la energía de un hogar. Entre más baja sea la calificación del índice HERS en un hogar, más eficiente es la energía en el hogar. El promedio nacional de la clasificación HERS publicada por RESNET es de 58.

“El hogar de muestra de Turning Leaf Construction en Winter Park es un hogar de rendimiento extremadamente alto que logra una clasificación de HERS de -22”, dijo Nate Ritter, Director de Sustentabilidad de GreenBuilt Solutions. “Va más allá del consumo energético nulo. Una de las características más importantes en los hogares de alto rendimiento es comenzar con un cerramiento hermético bien aislado como el de ICF. [Al usar a Fox Blocks], las ICF ayudan a proporcionar temperaturas estables de aire en interiores lo que reduce considerablemente las cargas de enfriamiento y calefacción, así como el costo.

“Cuando se construye un hogar, uno tiene una sola oportunidad para construir correctamente el cerramiento. Tiene sentido utilizar el sistema de muros más eficaz disponible como las ICF. Los propietarios de hogares pueden agregar PV para reducir sus recibos de luz; con las ICF [de Fox Blocks] puede agregar mucho menos y aún lograr un consumo energético nulo”.

Net Zero Home With Record-Low HERS Index Score

Español | Translation Provided by the CFA

Fox Blocks, an Insulated Concrete Forms (ICF) manufacturer, in partnership with GreenBuilt Solutions, a sustainable design facility in Orlando, FL, has managed to build a Net Zero home that has an outstanding HERS Index Score of -22.

The Home Energy Rating System (HERS) Index is the industry-wide standard energy-efficiency measurement of homes. It is also used to determine a home’s energy performance. The lower the HERS Index Score on a home, the more energy-efficient it is. The national average HERS rating posted by RESNET is 58.

“Turning Leaf Construction’s Parade Home in Winter Park is an extremely high performing home achieving a HERS rating of -22,” says Nate Ritter, Director of Sustainability for GreenBuilt Solutions. “It is beyond Net-Zero. One of the most important features in high-performance homes is starting with a well-insulated air-tight envelope like ICF’s. [Using Fox Blocks], ICFs helps provide stable indoor air temperatures, significantly reducing cooling and heating loads and cost.

“When building a home, one only has one chance to get the envelope right. It makes sense to use the most efficient wall system available like ICFs. Homeowners can add PV to reduce their energy bills; with [Fox Blocks] ICFs they can add much less and still achieve Net-Zero.”

Fox Blocks anuncia nuevos recursos adicionales ahora disponibles en español

English | Translation Provided by the CFA

Fox Blocks, fabricante formaletas aislantes para concreto, con mucha anticipación anuncia que ahora tenemos recursos nuevos en español. Esto es un programa de desarrollo emocionante para la empresa, ya que ahora podemos hacer que la información sea más accesible para el grupo demográfico hispanoparlante. Estamos orgullosos de ofrecerles la información por medio de nuestra página web bajo “Biblioteca de Recursos”. Atentos a nueva información próximamente.