For Sale: Used 2019 Truck Crane

A CFA member is looking to move a used 2019 Western Star with an Atlas 440 crane. The truck has an 8LL and 20,000 pusher. The engine is a 505 Detroit that has 34,000 miles on it.

The truck will be available in October and the asking price is $265,000. For more information contact Chris at (401) 348-9100.

How One CFA Member is Growing and Diversifying by Taking Control of Their Concrete

By Kris Moorman

CFA member, Custom Concrete, a family-owned and operated organization that is headquartered out of Indianapolis, strives to be the industry leader in providing concrete solutions. They specialize in residential, commercial, multi-family, and room-addition foundations. Due to the current industry demands, Custom Concrete had its busiest year in 2021 in over a decade. With scarce materials and high demand for ready-mix trucks, the company looked to volumetric technology for a solution.

Custom Concrete is not alone. Across the country, the number of residential, commercial, and industrial building projects continues to rise with no indication of a slowdown in sight. Many concrete contractors are looking to the latest smart volumetric technology to expand their current businesses for current and future needs.

Supplying the Demand

SiteSource, a subsidiary of Custom Concrete, became the solution to a growing issue. Jeff Davidson, operations manager at SiteSource, said, “We were having difficulties getting concrete when we needed it due to high demand, which made completing current jobs and planning for future work a challenge.”

Adding volumetric mixers to the fleet has allowed Custom Concrete to get concrete anytime and increase overall productivity, therefore increasing their capacity to fulfill more projects. “Our volumetric mixers allow us to pour short loads – a four-yard stem wall or two-yard footing repair – and send the ready-mix trucks to other jobsites so we can maximize our fleet,” said Davidson.

In searching for a volumetric solution, leaders at Custom Concrete selected the Cemen Tech C60 volumetric mixer equipped with ACCU-POUR™. “From the equipment, quality of technology, and customer support, Cemen Tech really stood out to us,” said Davidson. “After seeing all that’s offered with ACCU-POUR and the data it can provide us to make more accurate business decisions, we knew that it was going to be a perfect fit.”

Innovative Technology

A volumetric mixer measures, mixes, and dispenses a precise amount of concrete from one unit. Sand, stone, cement powder, water, and additives are each kept in their own bin to be mixed on-site and on-demand, eliminating the costs associated with hot loads or over-ordering. Waste is limited to a couple of shovels of concrete versus potentially yards of material, saving the operator and customer money by paying for only what is produced.

“Volumetric technology allows contractors to produce their own concrete when, where, and how they need it,” said Mark Rinehart, vice president of sales and marketing at Cemen Tech Inc. “Being able to do concrete work themselves puts full control of a contractor’s project in their hands, which can improve productivity, efficiency, and costs.”

When Custom Concrete made the decision to add volumetric mixers, they did extensive research to find the right solution. “We looked at a couple of different brands, and Cemen Tech offered a lot of benefits to our team. The two deciding factors were the equipment construction and the innovative technology solutions provided by Cemen Tech,” said Sam Gibson, business development manager for SiteSource. “We saw the benefit of ACCU-POUR and how it could be an asset to our business. The data would allow our team to make strong strategic decisions to propel us forward.”

SiteSource uses ACCU-POUR daily for all dispatching, billing, invoicing, and inventory tracking. “What we found was we really needed to boost our ready-mix allocations. The industry is overwhelmed, and construction is booming in central Indiana. Our team needed to find a way to fill the gaps, and Cemen Tech allowed us to do so,” Gibson said.

Plan. Tap. Pour.

Using ACCU-POUR, contracts can schedule jobs, assign projects, and send orders wirelessly to the operator’s tablet in the mixers. Orders are loaded in sequence and include directions for getting to the jobsite via the system’s GPS feature. Managers program the requested mix and quantity desired for each job, making it quick and easy for the operator to select the design for each job with a tap on the screen.

The system allows operators to enter notes for individual jobs, upload project photos, and share batch tickets with inspectors. Batch tickets can be provided electronically or in a physical document right on the jobsite.

“With the technology that’s available on the volumetric mixer and the resources we have within our organization, our operators can grow by learning more about concrete and what it takes to get the job done,” Davidson said.

Designing the Future Through Data

From the office, management can track detailed information from the volumetric mixer in real-time. The mixer management system tracks the truck’s location, material usage, total yards poured, and completed jobs. Since all the information is stored using ACCU-POUR and mobile technology, all invoicing can be handled electronically.

For longer-term planning, ACCU-POUR syncs data and historical details by job, customer, and date. This information is saved to the cloud, where management can access and review it at any time. Business owners can use this data to improve budgeting, ordering, cost inefficiencies, new opportunities for their business, and more.

“Our experience with ACCU-POUR and Cemen Tech has been phenomenal. They have thoroughly explained the benefits, system operations, and data management provided by the volumetric mixers. We have confidence we will be able to mitigate the gap in the industry for Custom Concrete through this new technology,” said Gibson.

Kris Moorman has worked in construction manufacturing for over five years. Her background in technology and sustainability, and the benefits that these both bring to the asphalt and construction industry, gives her insight into the ways firms can improve, diversify, and build their business. Moorman is the marketing manager for Cemen Tech, which manufactures volumetric concrete mixers.

Visit cementech.com

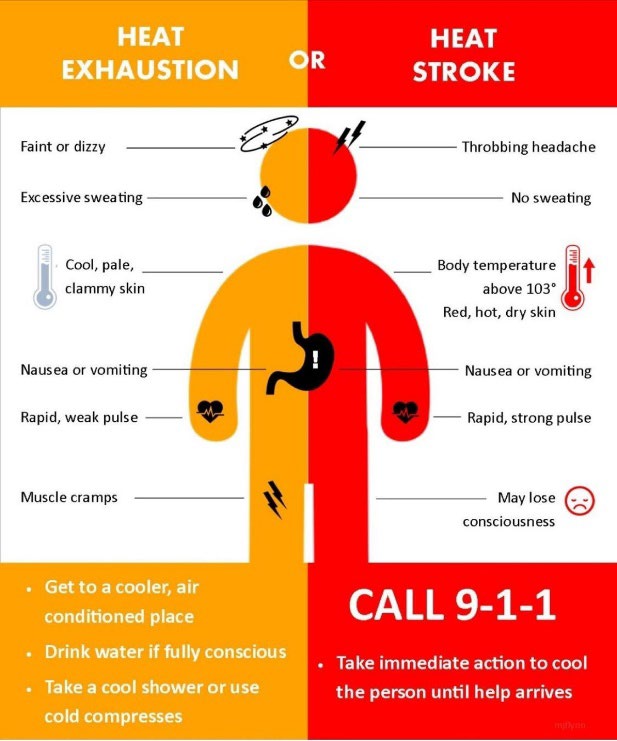

Federal OSHA Announced the Launch of a National Emphasis Program (NEP) On Heat Illness and Injury

by Tim Neubauer, MS, CSP, President of Exceed Safety LLC

When it is extremely hot and humid weather, your body’s ability to cool itself is diminished. If your body heats too rapidly it will use body fluids to cool itself. When this happens, too much fluid or salt is lost through sweating. The body temperature rises, and you may experience a heat-related illness. It is important that you know the symptoms of excessive heat exposure and the appropriate responses. To help you know these signs, OSHA’s revised Heat Illness Prevention webpage consolidates resources to keep workers safe indoors and outdoors.

Please visit their website listed here for more information:

New Oregon OSHA rules protecting workers from high heat went into effect On June 15th. A link to that article can be found here: https://osha.oregon.gov/pages/topics/heat-stress.aspx

Nevada OSHA is adopting the NEP in a modified form to reflect local factors. It will be effective on June 15, 2022. A link to that information can be found here: https://dir.nv.gov

The National Emphasis Program affects all industries including construction. The NEP can be read in its entirety at the link provided here: https://www.osha.gov/sites/default/files/enforcement/directives/CPL_03-00-024.pdf

For Sale: Used Steel-Ply Forming Panels

We have a set of used Steel-ply available. They consist of used frames with new plywood.

The set includes more than 200 pcs 24-in x 8-ft and more than 300 pcs 24-in x 4-ft.

We also have 100 pcs 24-in x 5-ft in Used in grade B condition and a good assortment of fillers and corners. Plenty wedge bolts- waler brackets- turnbuckles. Etc….

Call Andy 410 733 0748. Or Earl 610 659 7358

Visit us at pesale.com

For Sale: New Aluminum Form Sets

We have in stock at our Maryland yard a new set of aluminum forms manufactured by Aluform. They have a 6:12 hole pattern and consists of 60 pcs 36-in x 9-ft; more than 200 pcs 36-in x 4-ft; and 100 pcs 36-in x 2-ft.

We also have a new set of aluminum forms from Precise Forms consisting of 64 pcs 36-in x 8-ft also in a 6:12 hole pattern.

If interested call Andy 410-733-0748 or Earl 610-659-7358

Visit us at pesales.com

For Sale: 9-ft Precise Forms Aluminum Set

We have a good sized set of 32-in w x 9-ft tall aluminum concrete forms from the manufacturer Precise Forms. The hole pattern is a straight 8″. They are in grade B condition.

Lot includes more than 200 of the 32” with a good assortment of fillers.

If you have interest call Andy 410-733-0748 or Earl 610-659-7358

Visit us at pesales.com.

Discounted accessories for all CFA members. — We have plenty of nominal and full ties, pins and wedges, etc.

For Sale: New Aluform pre-seasoned panels

A CFA member has three lots of new, aluminum forms manufactured by Aluform. These are pre-seasoned forms on pallets ready to ship to your location.

For pricing or more information, contact John Harle with Star Lite Leasing, Inc. at (317) 201-8229 or johnh@weberconcrete.com.

Lot #1: Twenty (20) 14″ x 36″ smooth-faced panels with 6-12 hole pattern.

Lot #2: Thirty-two (32) 16″ x 36″ smooth-faced panels with 6-12 hole pattern.

Lot #3: Seventy-two (72) 36″ x 72″ smooth-faced panels with 6-12 hole pattern.

Lightning Awareness Week (June 19th – 25th)

by Tim Neubauer, MS, CSP, President of Exceed Safety LLC

Each year, nearly 1,000 people are struck by lightning in the U.S. alone. Lightning strikes cause deaths and people often suffer from neurological issues if they survive.

For construction workers, these dangers are magnified when site condition limit egress for the structure or the location is remote, and adequate protection is several minutes away!

OSHA requires and Emergency Action Plan that covers hazards, and if you work in an area prone to lightning, your plan should include a procedure for safe sheltering while on a construction site. Don’t risk it, once an alert is sounded, take cover immediately. OSHA has more guidance in their publication “Lightning Safety When Working Outdoors #3853”, and can be found at this link: https://www.osha.gov/sites/default/files/publications/OSHA3863.pdf

If there are other topics you would like me to write on, please don’t hesitate on responding to this article or reaching out to me at info@exceedsafetyllc.com.

Tight Market Conditions Briefing

May 2022 – Portland Cement Association

Introduction

Material specifiers frequently need to choose between concrete and alternative building materials. As concrete’s use has grown, cement shortages have begun to surface. Specifiers need accurate information about the shortage situation, and this briefing is an effort to provide the latest available information.

The Scope of Tight Market Conditions

Tight cement supply conditions vary by region but some evidence of tightness prevails in portions of 43 states according to PCA’s survey of cement manufacturers. In comparison, 28 states reported tightness in the spring of 2021. The tight cement supply conditions experienced during the past two years are a reflection of supply chain disruptions that have plagued the general economy. Where cement is in short supply, the reasons are typically threefold: strong cement demand, in some cases lingering disruptions associated with Covid-19, and logistics hinderances.

Strong Demand

Favorable winter weather last year resulted in strong consumption. On a seasonally adjusted basis, cement consumption in some of the winter months reached its highest levels since spring of 2007. Such strong consumption levels inhibit cement manufacturers’ ability to build inventories that are typically required to meet robust warm weather construction levels. Strong winter consumption conditions played a critical role in the emergence of tightness in 2021. These conditions repeated in 2022 – resulting in even stronger demand conditions than winter 2021.

Winter Inventory Build

Many cement companies build inventory during the winter months in preparation for peak summer construction season. Favorable weather conditions during the winter months generated stronger demand and hindered the ability to build inventories during typically slow cement consumption periods. According to PCA’s informal survey, spring order bookings remain strong and suggest the likelihood of strong near-term consumption levels.

Lingering Covid Disruptions

Furthermore, PCA surveys suggest some Covid-19 related production adjustments may have contributed to the lack of normal build-up of inventories that often materializes during the winter months. External contractor hours declined significantly in 2021. Some of these hours are accrued to specialized maintenance. Maintenance hinderances at cement manufacturing facilities can lead to unexpected temporary shutdowns which can aggravate shortages.

Import Disruptions

Port congestions and terminal disruptions have improved modestly since 2021. Despite this improvement, bottlenecks remain. Terminal disruptions, centered on the loading and unloading processes, have tied up ships, disrupting their normal flow. Port congestion has led to significant shipment delays. These delays can cause a ripple effect throughout the supply chain – including cement.

In addition to these difficulties, the war in the Ukraine has slowed exports to the United States from Turkey. Turkey imports one third of its coal from Russia. With the onset of hostilities, coal trade disruptions hindered Turkish cement production; such disruptions continue.

Turkey is the largest source of United States cement imports – accounting for more than 6.9 million metric tons in 2021 (more than even Canada’s 5.3 million metric tons). Turkish cement exports are concentrated on the U.S. east coast and states bordering the Gulf of Mexico. More than half of Turkey’s cement exports to the United States reach the Houston district ports; the Miami district accounts for 12%.

Logistic Hinderances

- The delivery of cement to the end consumer is heavily reliant on trucks and their drivers. Drivers are in short supply. This results in a slowing of cement deliveries.

- While only 17% of cement shipments to cement terminals travel via trucks, nearly all of the movement from terminals to final customers move via truck.

- Covid-related rail and barge disruptions also remain. These hinderances slow the cement products’ delivery to market and can account for transitory supply tightness. Even small temporary disruptions in shipments can cause turmoil in a geographic region. Notably, the Surface Transportation Board has recently taken action to assess and monitor wide-spread rail disruptions and service levels in an effort to facilitate improvements. The cement industry remains hopeful that over time the railroad supply chain will return to or even exceed previous “normal” operating conditions.

US Cement Supply Dynamics

The tight cement market conditions experienced during the past two years is a reflection of supply chain disruptions that have plagued the general economy. Some worry about the industry’s ability to meet upcoming demand associated with the infrastructure program. Many of the Covid-related supply chain disruptions will eventually fade – leading to improved supply capabilities.

PCA believes ample supply will be available to meet the demand associated with the infrastructure program. Consider the following:

- United States domestic cement capacity exceeds 106 million metric tons. In addition, more than 42 million metric tons of import capacity exists – bringing total cement capacity to 148 million metric tons.

- Supplementing this capacity, the United States cement industry continues to invest. Two U.S.-based plants are expanding capacity that by 2022 will add an additional 2.0 million metric tons of capacity. Permitting is underway for two greenfield sites that could add another 1.7 million metric tons of capacity. These investments come in the context of the industry’s ongoing investments to reduce its carbon footprint.

- In addition, several cement manufacturers have transitioned production, in whole or in part, from ordinary Portland cement to Portland limestone cement (Type 1L or PLC) as a key step to reduce the carbon intensity of cement and which, significantly, also leads to an increase in U.S. cement production capacity. These transitions to Type 1L and other blended cements are expected to continue as the U.S. cement industry supports future needs while also pursuing its roadmap to carbon neutrality.

- Aside from ample supply-side capabilities, it is likely that rising interest rates will result in some softening in residential and nonresidential demand for cement. This likelihood lowers the potential maximum cement consumption associated with the first few years of the recently passed infrastructure legislation. This potential demand side easing of consumption should contribute to the industry’s ability to meet infrastructure-related needs.

Concrete Foundations Convention 2022 (#CFACON22)

If you’re in the cast-in-place concrete industry, there is no better place to be in order to position yourself far ahead of your competition.

Concrete Foundations Convention 2022 (#CFACON22) heads to the northeast to be part of the historic culture and context of the Freedom Trail and the birth of our Country. Boston, Massachusetts is our destination and our host venue is The Westin Boston Seaport District. You won’t want to miss this opportunity to join your colleagues, bring your family and celebrate with some of the most historic cultural aspects of our country. If you are in the cast-in-place concrete industry, come join us for three days of education, networking, awards, exhibits, product demonstrations, large equipment display and much more!

As always, this year’s education program is designed for companies ranging from 2 employees to 3,000+ employees. No matter the size of your operation, you are sure to gain a tremendous amount of knowledge and learn from those who have been in your exact position. From Growth Cultures, to Hiring Systems, and Alternative Reinforcements to Industry Forecasting, you cannot afford to miss this important industry event!

“I am most looking forward to reengaging after being absent during the Pandemic. Ideas flow and friendships grow when we are face to face.”

– Jim Bartley, The Bartley Corporation

CFACON22 SCHEDULE AT-A-GLANCE

Day 1 – Thursday, July 7th

CFA Board of Directors and invited Guests (open) 10 am – 2:30 pm

Shuttle begins departing for Topsfield Fairgrounds 3:30 pm

Product and Equipment Fair at Topsfield Fairgrounds Arena 4:00 pm – 7:00 pm

Awards Presentation During Event w/ President’s Address

Day 2 – Friday, July 8th

Welcome to Interdependence and #CFACON22 8:30 am – 8:45am

Growth Cultures – Jason Ells 8:45 am – 9:45am

Hiring Systems – Doug Herbert 9:45 am – 10:45am

Alternative Reinforcements – Mike Hancock 10:45 am – 11:45am Lunch w/ Exhibitors 11:45 am – 1:30pm

Keynote, Connor Lokar – ITR Economics 1:30 pm – 2:30 pm

90 ideas in 90 minutes 2:30 pm – 4:00 pm

Happy Hour in the Exhibit Hall 4:00 pm – 5:30 pm

Shuttles to Boston Tea Party Ships and Museum 5:30 pm – 6:00 pm

Friday Night Social – The Boston Tea Party Ships and Museum 6:00 pm – 8:00 pm

Day 3 – Saturday, July 9th

Hiring Inspiration – David Whitlock 8:30 am – 9:15am

Hidden Material Costs. Are You Paying More Than You Should? -Kojo Technologies Inc. 9:15 am 10:00am

Keynote Presentation – Rocky Bleier 10:00 am – 11:00am

Book Signing / Photo Opportunities 11:00 am – 12:00pm

Closing Remarks 11:45 am

Closing Social – NY Yankees @ Boston Red Sox – Fenway Park 7:15 pm

(Pre-Registration Required)

Register, reserve your room and find out more at

bit.ly/CFACON22

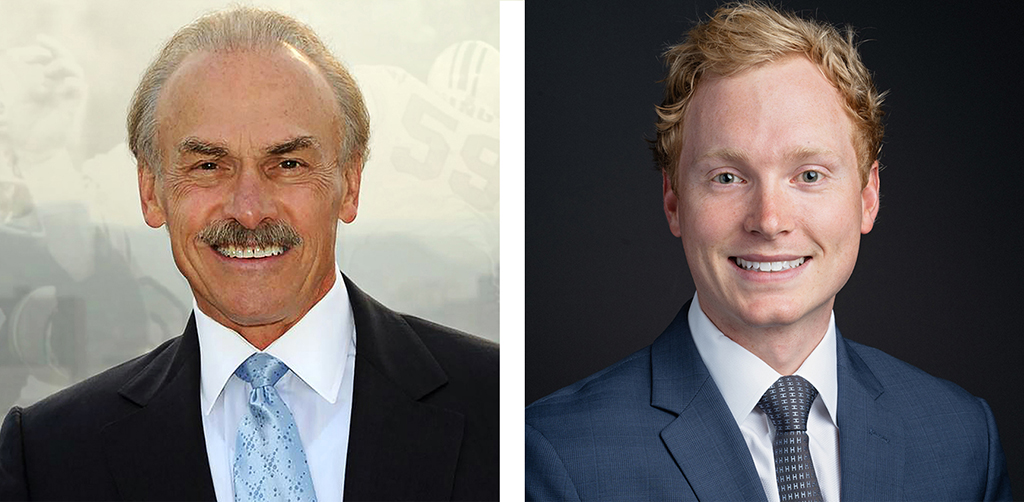

FEATURED KEYNOTE: ROCKY BLEIER / FEATURED PRESENTER: CONNOR LOKAR

Vietnam Vet and Four-Time NFL Super Bowl Champion. Rocky Bleier’s life story – a gripping tale of courage on both the football fields of America and the battle fields of Vietnam – has held audiences in rapt attention for years. Yet, the motivational message behind it, detailing how ordinary people can become extraordinary achievers, defines success in the new American century.

“Admittedly, I’m not a sports guy…so I was not sure what to expect when going to hear Rocky Bleier for the first time. I’m happy to say, that his story is so inspiring! I walked away not only encouraged but inspired to think big, and challenged to not make excuses. I’m now a huge fan of Rocky Bleier and I’m excited to hear him again!”

– Jason Ells, Sr Vice President, Custom Concrete

As Senior Forecaster for ITR Economics, Connor Lokar presents with authority, accuracy and humor. He specializes in construction industry forecasting, helping business owners grow revenue and remain profitable through an ever changing business cycle. If you want to know what is going to happen with the economy and with home building in the next six months to few years, you will not want to miss this keynote address!

“At Hottmann, we have been followers of ITR Economics for over 10 years. We have reliably considered their economic forecasts in making strategic decisions about our future, and their reports are both informative and easy to read. I would highly recommend them as a resource to any business!”

-Ken Kurszewski, Hottmann Construction

Growth Cultures, Hiring Systems and Hiring Inspiration. In what ways are you challenged to achieve success as the ideal employer in your market? Every employer in North America faces the unprecedented challenge of attracting employees to the deficit of a quality workforce. Construction couples this with the generational indifference to hard work…or does it? Participate with JASON ELLS of Custom Concrete as he focuses on advancing a Growth Culture in a presentation about consciously evolving and improving your company culture to establish the best platform for attracting and retaining top talent. Participate with DOUG HERBERT of Herbert Construction as he delivers Hiring Systems with a presentation looking at the need for intentional hiring systems and how to evaluate their importance. Further clarify and qualify with

DAVID WHITLOCK, ESQ with his Hiring Inspiration presentation that helps you determine how to do enough to comply without creating obstacles by overdoing the hiring process. In addition to the workforce development presentation MIKE HANCOCK will present “Navigating Acceptance for Reinforcement Alternatives”. Micro fibers, macro fibers, glass, synthetic, steel fibers, micro-reinforcement, GFRP, carbon fiber bar…the list continues to mount for ways to replace deformed steel rebar in concrete structures. These alternatives are attractive in price, availability and labor efficiency. However, are they able to be used and how do you obtain approvals? As an engineer and concrete contractor, I have first hand experience of evaluating, seeking and attaining approval for various applications and “it ain’t always easy.”

EDUCATION SPONSORED BY

___________________________________________________________________________________________________

Exhibits

The exhibit hall at the Concrete Foundations Convention features the newest and greatest products and technology that the industry has to offer. Exhibiting companies offer products that will save you time, money, and improve the look of your next project. These companies are the backbone to the association, and their investments allow us to expand education and continue to serve your industry.

Join industry leading suppliers and manufacturers at the Topsfield Fairgrounds Arena on opening night (shuttles provided), and back at the exhibit hall at the Westin on Friday to explore new products to help save time, money, and improve the look of your next project! Enjoy your drink of choice as you visit with exhibiting companies and become reacquainted with old friends, all while developing new relationships that will have a lasting impact on your business.

Dedicated Exhibit Hours:

Thursday, July 7 – 4:00pm – 7:00pm – Products and Equipment Fair (Topsfield Fairgrounds)

Friday, July 8 – 11:45pm – 1:30pm – Lunch with Exhibitors (Exhibit Hall at the Westin)

4:00pm – 5:30pm – Happy Hour with Exhibitors (Exhibit Hall at the Westin)

Exhibiting Companies

Badger Forms*, Boman Kemp Basement Windows, Concrete Forms Services, LLC*, Cranes & Equipment* CrewTracks, Euclid Chemical, Form-A-Drain*, Fox Blocks*, GMX, Inc.*, Helix Steel, ICC Distribution Group, LLC*, Irving Equipment, LLC*, Kojo Technologies Inc., Max Frank, MAX USA, Nox-Crete, Inc.*, Novoform*, Owens Corning*, Prinsco, Inc., Progressive Foam Technologies*,Robotic Surveying Solutions, Rockwell Window Wells, Schwing America*, Starlight Leasing*, Steel Dog, Transit and Level, Tremco Construction Products Group*, TUF-N LITE*, Western Forms*, White Cap*

*Event Sponsor

For a full list of exhibitors please visit bit.ly/CFACON22

Attend the Products and Equipment Fair

Topsfield Fairgrounds*

Thursday, July 7, 4:00pm – 7:00pm

This year the CFA is taking attendees to the Topsfield Fairgrounds Arena for opening night! Shuttles will be available throughout the evening, allowing attendees and their families to get hands on with the industry’s top products and heavy equipment. Enjoy food, drinks and entertainment as you visit with exhibiting companies and become reacquainted with old friends, all while developing new relationships that will have a lasting impact on your business.

*Included with all registration types

Spoil Your Guests and Family While You’re in Education*

Guests/Spouses Only | Friday, July 8, 11:00am – 2:00pm

Back by popular demand, the 3rd Annual Guest Social will take place Friday afternoon while business attendees are deep into education. Bring your family and/or special guest to the event and sign them up to experience a lunch cruise on Boston’s favorite yacht, the Spirit of Boston, to mingle and become acquainted with other guests/spouses.

Boarding will begin at 11am right in the Seaport District, guests/spouses will enjoy a 2-hour cruise on the Boston Harbor. Included is a delicious lunch buffet with freshly prepared entrees, salads and desserts, drinks, onboard entertainment, an open-air lounge for games and relaxation, and the absolute best views of the Boston skyline and iconic waterfront landmarks – There’s no better way to see the city than from aboard the Spirit of Boston!

*This lunch is during education hours, and intended for guests/spouses only. Additional registration required. Space is limited.

“I attended the 1st Guest Social and felt welcomed right off the bat! I met so many amazing people that day, and I have never felt this at any convention before. Having the Guest Social made me feel more involved, and I was able to relate to others who are in the same position as myself within this industry.” -Roxanne Roffers

Enjoy Drinks with Exhibitors*

Friday, July 8 – 4:00pm – 5:30pm

The exhibit hall features the industry’s top suppliers and manufacturers. Enjoy your drink of choice as you dig deeper into the companies you were introduced to on opening night! Exhibitors have the products and services that will help you save time, money and improve the look of your next project.

*Included with all registration types.

Socialize at The Boston Tea Party Ships and Museum*

Friday, July 8 – 6:00pm – 8:00pm

Directly following Happy Hour in the exhibit hall, the CFA is taking you and your family to one of Boston’s most popular areas on Friday evening of this year’s event – The Boston Tea Party Ships and Museum. You’ll will enjoy food and drinks while networking on Griffin’s Wharf, and have the opportunity to travel back in time to 1773 and re-live the battle and events and see fully restored replicas of the ships throughout the evening – Come experience the Boston Tea Party Ships and Museum like never before!

*Included with all registration types. Please rsvp during registration.

“I make it a priority to come every year because there is always something to be gained by coming and talking to other members. These are trying times with inflation as high as it is and labor as short supply as it is so getting others thoughts about these issues will be very helpful.”

– Bruce Neale, Modern Foundations

Attend the Legacy After Party*

Friday, July 8, 8:30pm

Directly following the Boston Tea Party Ships and Museum Social, join your peers for a night cap at the Legacy After Party. This event, hosted by the Legacy Committee, will take place in the Pavilion right outside of the exhibit hall at the Westin, and is a great way to wrap up day 2 of convention!

*Included with all registration types.

Watch the Boston Red Sox take on the New York Yankees*

Saturday, July 9, 7:15pm

The CFA is excited to announce that we have reserved a private space inside of one of Boston’s most iconic landmarks, Fenway Park, for this year’s closing social. Tickets are limited to the first 100 people to register for the closing social. While the Boston Red Sox take on the New York Yankees, guests will enjoy access to our private space, an all you can eat 2-hour BBQ buffet, 4 hours of open bar which includes beer, wine, soda, water and snacks, and unparalleled views of the field. Tickets are limited. * This event is SOLD OUT.

“We love going to the different locations. I say we, it’s become a family trip for us. It sounds corny (because it is) but the association has become a real community for us. Scott Carter (Robotic Surveying Solutions) spent a Labor Day weekend at our house because he happened to be in the area that year. My kids can’t wait to see the Irving’s (Irving Equipment) every year. I like getting a very honest opinion on something from Dennis Purinton (Purinton Builders) and Mike Hancock (Basement Contractors). It’s like going to World of Concrete but in a different spot every year, none of the Vegas craziness and it’s all tailored to foundation contractors. Just a nice couple days away and you usually come away with something.”

-Russ Talpey, Talpey Construction

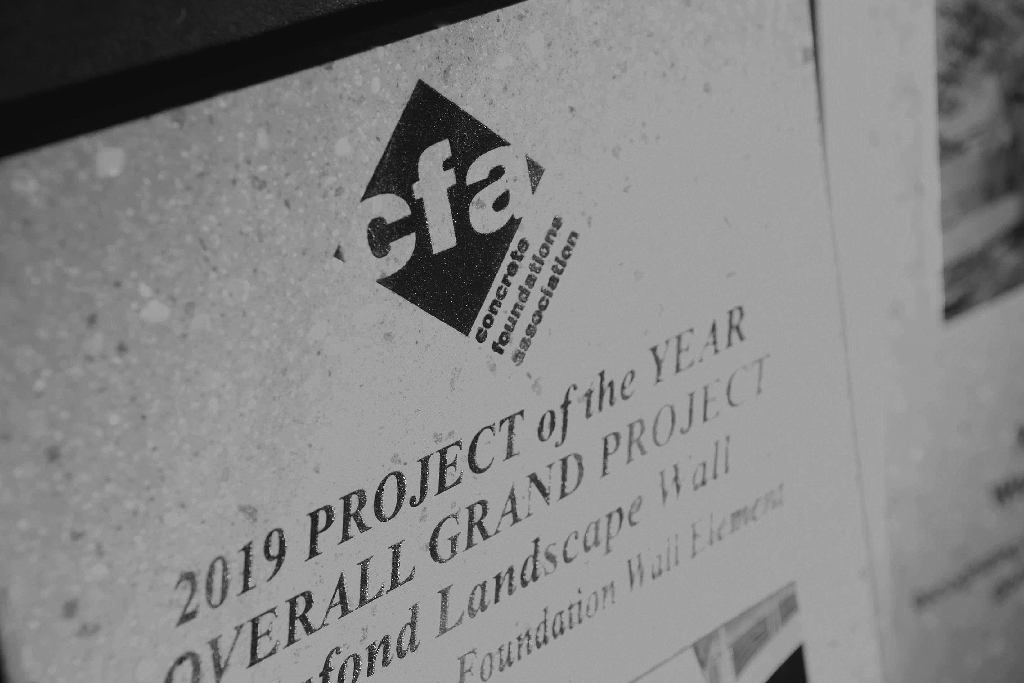

2022 Award Presentations

Thursday, July 7, 5:30pm

Topsfield Fairgrounds

Join us as we present the 2022 CFA Awards during the Products and Equipment Fair on opening night! Shuttles will be provided from 3:30 – 7:30pm to and from the Boston Westin Seaport District hotel.

Like all industries, the cast-in-place concrete industry is filled with individuals and organizations that demonstrate the highest ideals of professional knowledge and technical service. Likewise, the projects that are achieved are often a combination of great creativity and technical expertise that evidence exceptional quality…unfortunately, many of them are covered up as foundations and therefore overlooked when the project has been completed. The awards offered and promoted by this Association are aimed at uncovering this talent and quality and permanently affixing them into the landscape of concrete history.

Awards are offered annually in two main categories: (1) Projects,

(2) Professional Achievement. While nominations and participation in these award programs are a benefit of membership, companies can seek membership in order to participate in these opportunities for recognition and elevate their stature in the marketplace.

#CFACON22 is Proudly Sponsored by