It’s a Great Time to be a Member of the CFA

Doug Herbert

Herbert Construction Company

doug@herbertconstruction.com

A lot has been happening here at the Concrete Foundations Association.

The CFA convention in Boston is right around the corner. This event has an outstanding lineup of speakers and activities planned. We’ll hear from NFL legend, Rocky Bleier. Economist Connor Lokar will be there to tell us what the future may hold for the construction industry. We also have three different presentations geared towards your most pressing issue: finding and keeping employees.

Plus, there will be three evening social events that include a unique vendor showcase, a “Boston Tea Party” in the harbor, and a Yankees vs. Red Sox game at historic Fenway Park.

You can read more about the wonderful event on other pages of this magazine. I hope to see you at Convention!

The convention coincides with our board of directors meeting. New members will join the board as some of our current members depart. I am grateful for the time and effort our current members put into their time on the board. Thank you. And, I am looking forward to the new board members’ input as we continue to be the best association for concrete contractors.

At the end of the convention, there will be a changing of the guard within the executive committee. Chairman Phil Marone will leave the board after many years of distinguished service. My term as president will end and I will move into the chairman position. Our current vice president, Jason Ells, will become the new president.

I want to thank our executive committee members: Phil Marone of Marone Contractors Inc., Jason Ells of Custom Concrete Company Inc., Sean Smith of MPW Construction Services Inc., Ken Kurszewski of Hottman Construction Company Inc., and Jim Baty of CFA. They made these two years of my presidency a great adventure. It is incredible what we accomplished.

During my two-year term, we navigated the CFA (and our own businesses) through COVID-19, our first virtual convention event, a wall-tie shortage, and a months-long strategic planning session that spawned multiple task forces and clear objectives for the association.

We focused on what concrete contractors needed and went to work creating solutions for them.

That focus will remain. The board of directors and the CFA staff will continue creating valuable resources and providing networking opportunities for our members. Here is just a glimpse of what we are working on:

Online courses your office and field people can take to improve their skills and become more valuable.

Pre-designed images you can use on your websites and social media channels to attract new employees.

Manager/Owner-level networking groups that meet throughout the year to improve each other’s businesses.

Templates you can modify that show the potential path from a newly hired laborer up to a foreman position, to improve your hiring process and employee retention.

If you are a CFA member, look for these and other initiatives in the months to come.

If you aren’t a CFA member and you are in the concrete industry, then you are missing out. Your competitors that are CFA members have an advantage that you don’t have. You should become a member to utilize our resources and improve your business.

It has been an honor to serve as the president of this terrific association. I am thankful for the phenomenal experience.

Let’s Make Change Great…Always

jbaty@cfaconcretepros.org

As a regular reader of Concrete Facts, I hope you recall the article announcing the retirement of our long-time staff member, Janette Barr (Concrete Facts 29-2, winter 2022, p. 23). As we published that article, I was considering the impact of employment transitions I have been experiencing through the witness of so many of our members over the past decade. When you have worked in an industry for 30 years, as I have, you are most certainly going to recognize the voids left by leaders retiring, some untimely passing from this earth, and many more casualties of first a recession and then a pandemic. I have seen the change in most of these cases from afar and can now recognize more fully the measure of stress this change induces.

Welcoming the new challenge-seekers, the ready-leaders, the inspired-doers has also been a tradition I have witnessed among our member contractors. Many of these I have been privileged to engage with professionally, as these leaders have risen to the Association’s board or committee level. At present, there are only five members of the board who were elected prior to 2018. This means that 75 percent of the board are leaders whose vision must come more from their organizational needs than building on tradition or legacy. This summer we will see another significant step as Phil Marone, president of Marone Contractors and a CFA member since 2000, steps aside following an astounding six terms (he joined the board in 2005).

These transitions have been building blocks for success in the Association, and we are excited to welcome change into our staff that serves you with fervor. Abbie Stolte has accepted the role of office administrator, which includes A/R, A/P, fulfillment, circulation, and registration management. You will begin the enjoyable experience of recognizing her voice, witnessing her efficiency, and relying on her effectiveness.

Filling the void left by a thirty-year personality is never an easy task. Still, we know having Stolte join our team will be helpful for each of you, and that this change will continue to be great for us. Just like the board of directors, which now sits at 75 percent new experience and energy, our association staff is being invigorated, with 40% having less than a year of experience and 70 percent having less than 10 years of experience. What we can do for the members of this Association today, as your professional staff and board of directors, is 150 percent due to the balance we have arrived at between fresh energy and trusted legacy. I hope your business can claim the same and lean into what the CFA now offers. If you are struggling to do so, reach out to us and let membership open the door through staff and Expert Connect.

Diversity Equity and Inclusion

By Kimberly Kayler, CPSM DEI Practice Leader, AOE President Certificate in DEI by

the University of Michigan

Building on almost 25 years serving technical industries in an organizational, strategy and marketing role, Kimberly leads the AOE DEI practice. Trained in DEI by the University of Michigan, she brings a wealth of experience in organizational development, HR, training, strategic planning and stakeholder engagement to her role. Another key area of her expertise that aligns with DEI is crisis communications. She is certified by the National Transportation Safety Board in crisis and media relations, and is known throughout the industry as one of the top professionals in this arena. As the lead of the AOE DEI portfolio, she will ensure best practices are applied to the delivery of all services as well as the establishment and monitoring of return on investment.

Recently selected as one of the most influential people in the concrete construction industry by Concrete Construction magazine, Kimberly received her BA in journalism/English from The University of Arizona, and currently serves as a mentor at the University and is on the Alumni Board of Directors. She earned her master’s degree in organization and management with an emphasis in leadership from Capella University.

More and more, people and organizations are making decisions about who they work with and for based on Diversity, Equity and Inclusion (DEI) policies, theories and practices. While social issues have certainly driven the most recent focus on DEI, so has the trend of consumers feeling empowered to force organizations to change. In fact, 65 percent of respondents to a 2019 Edelman survey indicated that they would choose, switch, avoid or boycott a brand based on its stand on societal issues. Add the speed with which we share information, and DEI is at the forefront of our lives.

While consumer choice, societal pressure and a moral imperative make DEI a focus for many, you may wonder how this trend applies to the concrete industry. The growth of DEI interest and programs actually has many implications as well as benefits for our industry and our broader communities as well. Not only is DEI a potential solution for our long-term workforce development challenge, but an organization’s DEI policies may be a deciding factor in terms of whether or not you are selected for a project. Many large institutions, from universities and governmental agencies to large corporate buyers and higher education institutions, have added DEI requirements to their Requests for Proposals—an imperative architects, engineers and contractors are trying to figure out as there is no singular industry definition as to what is meant by DEI. However, what is known is that DEI initiatives and programs are only going to increase in our industry.

Defining DEI and Its Benefits

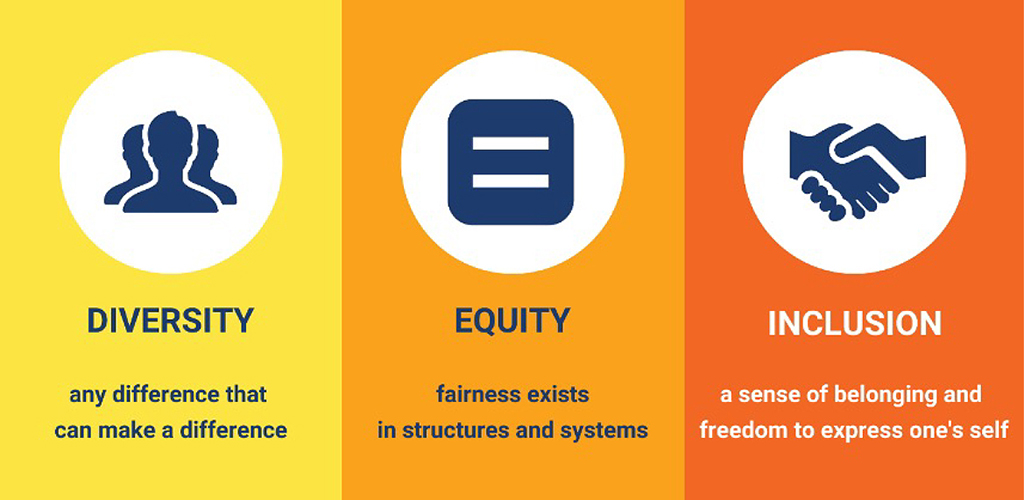

It is important to start with definitions of Diversity, Equity and Inclusion to help frame the conversation around this important topic:

DIVERSITY: Too often, our society thinks of Diversity only in terms of race. Rather, Diversity represents the individual differences members may identify with or as, such as they relate to their social and professional identity. Consider the presence of “difference” within a given setting. Differences can arise in our appearances, thoughts, likes and dislikes, values, and identities. Diversity among identities may relate to gender, race, ethnicity, religion, nationality, education, marital status, sexual orientation, (dis)ability, and socioeconomic status, to name a few. Professional identity should also be considered. Factors include job type, departmental bias, tenure, worksite, location, employment status, responsibilities, education, training and more.

EQUITY: While ‘equality’ means ʻsameness,’ Equity means fair treatment, fair access, fair opportunity and fair advancement for all people. Equity is an approach that ensures everyone is supported in their personal and professional development. Unlike equality, equity does not aim to treat all individuals in the exact same way. Instead, equity recognizes that advantages and barriers exist.

INCLUSION: The act of creating environments in which people feel like they can bring their authentic selves to work is Inclusion. It means everyone feels valued, respected and appreciated for their unique identities, even when they’re different from others. Inclusion outcomes are met when you, your institution, your policies and programs are truly inviting to all. Inclusion also extends to the degree in which diverse individuals can participate in decision-making processes and development opportunities.

Benefits of a DEI Program

A DEI program can serve as the cornerstone of an organization’s efforts to be responsive within an organization and the communities in which their employees serve, work and live. While DEI is new to many and can be a challenging topic to not only discuss but figure out how to tackle, the benefits for the concrete industry are proven. DEI programs, when implemented correctly and tied to an organization’s strategic and business objectives, have proven to benefit an organization’s bottom line by creating a competitive advantage in many ways:

- Financial performance: A study conducted by McKinsey & Company found that ethnically diverse companies are 35 percent more likely to have financial returns above their respective national industry medians. Gender-diverse companies are 15 percent more likely to outperform their respective national industry medians.

- Employer of choice: According to Glassdoor, 67 percent of job seekers view a diverse workforce as an important factor when evaluating companies and considering job offers.

- Innovation and growth: Harvard Business Review found that diverse companies are 70 percent likelier to capture a new market. They’re also 45 percent more likely to report increased market share year-over-year.

- Increase employee engagement: 83 percent of millennials report being actively engaged when they believe their organization fosters an inclusive workplace culture. This drops to 60 percent when their organization does not foster an inclusive culture.

- Powerful decision-making: Teams that are inclusive make better decisions up to 87 percent of the time, according to a study conducted by Forbes.

DEI also has a direct link to workforce development – a key focus of the concrete industry for the last two decades. Could DEI be a solution? Many think so. Being an employer of choice is also a key factor driving interest in DEI. In response to job seekers examining potential employers’ DEI initiatives before accepting offers, employment search platforms such as Glassdoor and Indeed both rate organizations based on diversity efforts.

One of the keys to being an employer of choice is recognizing our changing workforce. There are now five generations in the workforce ranging from the Silent Generation (born between 10928-1945), Baby Boomers (born between 1946-1964), Generation X (born between 1965-1980), Millennials or Generation Y (born between 1981-1996) and the newest segment Generation Z (born since 1997). Each generation bring a mix of employee expectations around topics of reskilling/upskilling in the age of automation/technology, holistic employee wellness, connecting work to social impact and purpose, flexible work arrangements, social media outside the workplace and more that will affect DEI training for this modern workforce.

Sidebar: Positive outcomes of organizations with DEI strategies include

- Diverse teams are more innovative and are better equipped to solve complex problems

- DEI is connected to employee engagement, job satisfaction and retention

- Diversity and Inclusion impacts reputation and risk management

- Focused corporate social responsibility and sustainability

- Limit legal liability

Defining and Designing a DEI Program

One of the biggest misconceptions about DEI programs is that it is yet another government program that measures quotas. But, if DEI isn’t about quotas and numbers, what are we measuring? The answer depends on your DEI plan and your core objectives as they relate to your strategic operations. It is important to recognize that all organizations are on a DEI journey, and a DEI program helps you determine where you are and where you are headed. A solid DEI program should not be punitive or shaming in terms of where an organization is today. It should outline where the organization wants to head with its DEI efforts.

The purpose of creating a DEI strategy is to define the short-term and long-term goals, priorities and initiatives for the organization. The process provides direction on how to achieve these objectives. This includes:

- Creating a DEI internal and external statement.

- Continuous DEI educational programs for the team.

- A DEI Communication plan which communicates the DEI mission/vision and strategy internally and externally; includes the onboarding process; and defines their digital brand to include DEI information on the website and in social media.

- Designing a talent pipeline focused on increasing diversity in the hiring, promotion and succession planning process.

- Listing the initiatives on which the firm decides to focus (based on the survey and data collection).

- Defining metrics and creating a tracking process.

Chances are there are already some DEI practices in place at your organization, especially in HR activities. However, a DEI effort should not be considered solely related to hiring practices, and efforts should expand beyond EEO compliance and affirmative action. Although organizations commonly use basic workforce demographic measurements (minority, veterans, female representation, etc.) for compliance reasons, most fail to measure any other factors such as diversity within leadership, job titles or recruiting outcomes. Diversity is a more inclusive concept and includes people of various religions, marital status, sexual orientation, economic status and a variety of other states of being. Diversity and affirmative action deal with issues related to discrimination, but in different ways. They are complementary in function, but different in their goals. While affirmative action focuses on taking positive steps to get individuals into the organization, diversity in the workplace works to change the culture within. DEI is about your employees and vendors feeling included. It is about your culture. It is about growth and movement. Do you have a documented pipeline strategy for hiring? Do you track the demographics of candidates who apply for position? How do you know if you are reaching a diverse population of qualified candidates if you are not tracking these areas in your hiring practice?

DEI should be an important function of your organization just like marketing, finance, sales, etc., and led by a dedicated professional(s) whenever possible to achieve the best results. Small- and medium-size organizations that cannot afford to hire a full-time person can have their HR leader champion the initiative and leverage a committee/council to advance the program, with the CEO/leader being very involved and managing it from the top. No matter who leads DEI, it is crucial that the principles of your program are part of the fabric of your organization.

Another common stumbling block is that an organization may recognize that their workforce is not diverse, so they commit to recruiting and hiring a diverse population. However, the new hires don’t last in that environment. This is typically due to lack of programs that support engagement and inclusion in the organization. In essence, the organization is treating the symptoms but failing to assess culture and climate. It is key that tactics are tied to strategy, metrics and accountability; efforts go beyond recruiting programs; and all activities are aligned with the strategic objective.

Benchmarking measurement best practices include the following means to evaluate your organization:

- What are you doing in the workplace?

- What are you doing for the workforce?

- What is your role related to diversity in the industry or marketplace?

- How do you support DEI with your supplier community? Are you working and partnering with those who have DEI values?

How to get started?

Getting started on your DEI journey can be tough, but AOE—a long-time consultant to CFA and a firm serving the concrete industry for more than two decades—has responded to the need with the launch of a DEI Practice Group as well as the industry’s first online assessment tool. The practice group, which is believed to be the first of its kind launched specifically to serve the design and construction industry, was developed with the involvement of tenured DEI consultants and partners.

Because every organization is different and may vary greatly in where they are in their DEI journey, AOE’s DEI services center around a customized strategic plan. The process begins with an organizational snapshot obtained through AOE’s proprietary online Benchmarking Assessment tool. This tool goes far beyond measuring quotas and numbers—it also addresses DEI-related concepts including intent, language and visual messages, as well as how diversity, equity and inclusion are integrated into an organization from a strategic standpoint. Upon completion of the assessment, real-time data is provided including the degree to which the organization supports DEI and where they are in their journey (based on a proprietary maturity model). Feedback is provided along with a suggested roadmap to meet their DEI goals, which may include training such as implicit bias education, a branding audit or modification of recruiting activities. As the organization moves through the various phases of their DEI roadmap, AOE is with them every step of the way. Training is a key component of the new service offering.

Next Steps

Although there is no one-size-fits-all approach to assembling a DEI initiative for your organization, it is vital to start discussing its importance for your organization. A variety of short videos on the DEI topic can be found at www.aoeteamdei.com. For more information on how to navigate your organization’s DEI journey, please visit or contact Kayler at kimberly.kayler@aoeteam.com.

Jargon Junction

Micro-Aggression: A quick, small act or words that results in a slight or indignity. An example may be hugging your purse tighter when a Black man walks by, following a Black person around a store, or assuming a non-White person is service worker. Although the offense is never intended, micro-aggressions are cumulative. On their own, the act or words may not seem like a bid deal, but they add up and normalize racism, sexism, etc.

Microinequities: Micro-inequity is a theory regarding ways in which individuals are either singled out, overlooked, ignored, or otherwise discounted based on an unchangeable characteristic such as race or gender. These can be conveyed through facial expressions, gestures, tone of voice, choice of words, etc. An example is calling a woman “honey” or “sweetheart,” assigning tasks according to stereotyped roles (women as note-takers), confusing a person of a certain ethnicity with another person of the same ethnicity.

Systemic Bias: Prejudice or unfairness directed by a system or institution (health, religious, judicial, etc.) towards individuals of an oppressed or marginalized group, whether consciously motivated or from lack of exposure to issues important to marginalized communities.

Implicit (Unconscious) Bias: Prejudice or unfairness directed by someone (person) from a privileged group toward individuals from an oppressed or marginalized group, usually coming from a lack of exposure to issues important to marginalized communities. A common example seen in studies shows that white people will frequently associate criminality with Black people without even realizing they’re doing it.

A 10-Step Process that will Guide you through Building a Distracted Driving Policy

by Julia Kunlo, Evolution Safety Resources

The dangers associated with distracted driving are difficult to dispute. In 2017 alone, it is estimated that 391,000 drivers were injured in distracted driving crashes (Distracted Driving Statistics, 2019). Due to the recent spotlight on the topic, many companies have decided to implement their own distracted driving policies to protect their workers, their businesses, and their bottom line. If you are one of the many employers interested in a distracted driving program, where do you start?

Distracted driving is more than just cell phone usage. There are many facets of the topic to consider and decision-points to give thought to. This ten-step process will guide you through the questions and options to weigh while generating, distributing, and implementing a customized distracted driving policy.

1. Define Your “Why”

Before you begin to develop your policy, it is important to consider all the reasons your company wants a distracted driving program in the first place. Your corporate “why” will be used as a tool to solicit buying and support from management and field employees alike. Common motivators include:

- Reduction of risk to employees – In 2017, 3,166 people died in crashes involving a distracted driver (CDC, 2019). Preventing distracted driving in your company means protecting your most important asset, your employees, while they are on the road.

- Protection from legal implications – Recently, employers have been held liable for financial figures north of $20 million for employee crashes; these figures were upheld even when the crashes occurred using hands-free devices and in personal vehicles (On The Road, n.d.).

- Financial motivation – The average, non-fatal, distracted driving crash at work costs the employer $72,422 (CDC, 2019).

2. Define Your Scope

As you consider your distracted driving policy, think about when the policy will be applied and who it will apply to. A common recommendation is to include all employees at all levels of the organization, all vehicles in the corporate fleet, and all personal vehicles being used for company business. When discussing cell phone usage, consider including work devices as well as personal devices.

3. Consider All Types of Distracted Driving

The main forms of distraction behind the wheel can be broken down into three categories: visual (eyes off the road), manual (hands off the wheel), and cognitive (mind off driving) (CDC, 2019). Think about the different types of distractions for your drivers and consider including provisions for various situations, including (but not limited to):

- Talking on the phone

- Using bluetooth to make calls through the vehicle’s sound system

- Texting while driving

- Eating behind the wheel

- Driving while drowsy

- Entering data into a GPS while in motion

- In-cab distractions (children, coworkers, etc.)

- Personal hygiene behind the wheel

4. Ban Texting While Driving

Regardless of your personal beliefs, texting while driving is a “no” across the board. Texting combines all three forms of distracted driving (visual, manual, and cognitive), making it extremely threatening to the safety of your workers as well as the well-being of others on the road. When discussing texting while driving, there are a few important points you may wish to specifically highlight:

- Reading text messages behind the wheel, even if a response isn’t made, is still prohibited.

- Utilizing “voice to text” to send a message is just as dangerous as manually typing in the characters.

- Texting while at a stop light or a stop sign poses risks; only send messages when pulled safely off the road with the car in park.

5. Define Your Policy on Hands- Free Usage

Current law (in some states/municipalities) allows for workers to use their cell phones in a hands-free capacity while behind the wheel. This includes using the speaker function on the phone as well as the vehicle’s sound system via bluetooth. Recent case law, however, has held employers liable for figures above $20 million when determining fault for crashes when hands-free devices were utilized. Hands-free devices do not make driving any safer than hand-held devices; drivers using a cell phone in any capacity are four times as likely to crash (On The Road, n.d.). Although it may not be legally required, consider going above and beyond the law by banning cell phone usage in all forms while behind the wheel (including hands-free usage). To support this effort, drivers can place their phones in “Do Not Disturb” mode while behind the wheel.

6. Consider Technological Assistance

There are a plethora of apps, devices, and software systems available to support companies in the monitoring and enforcement of safe driving principles. Give thought to utilizing technological assistance, such as apps which lock cell phones while traveling at certain speeds, to ensure compliance with the corporate distracted driving program.

7. Define Your Discipline Policy

It is important that a discipline policy specific to safe driving be incorporated into your distracted driving program; the policy should clearly outline both the short-and long-term repercussions of specific offenses. For example, does going ten mph over the speed limit have the same repercussions as drafting an email response while operating a vehicle? At what point are driving privileges suspended and/or terminated? The elements of the discipline program must be clearly stated and consistently applied to all employees at all levels of the organization.

8. Consider Practical Implementation

A distracted driving policy must be practical and reasonable to be enforceable. Considering that you have expectations for your drivers during a workday, how will you make the policy a long-lasting implementation into daily activities? Put thought into new corporate rules and/or guidelines that will support your distracted driving policy, such as:

- During a teleconference, ask each attendee at the call’s onset if they are behind the wheel; if they are, instruct them to hang up and call back in once safely parked and off the road.

- Allow employees to eat breakfast during the morning meeting so they are not pressured to eat while driving to work.

- Explain the distracted driving policy on work phone voicemails so that calling customers understand and appreciate the potential lag time between call and response.

- Plan breaks into long road trips so that important calls and emails can be responded to in a timely manner.

9. Perform a “Soft” Roll Out

Who better than your employees to help you identify potential snags in your policy? Before disseminating the new distracted driving policy to the entire company, ask a few key members of your team to review it and provide feedback. Not only will this step result in practical ideas and solutions, but it will also create a team of supporters to help with buy-in once the policy goes into place.

10. Roll Out Your Policy

As is true with most corporate changes, in-person meetings are preferred to answer questions, gather excitement, and gain acceptance. Once your distracted driving policy is generated, hold a companywide meeting to discuss the plan and set clear expectations. Explain why the policy is important to the company and allow for plenty of time for questions, comments, and feedback. Pass out a copy of the policy and ask that each employee sign in and return it as a written record of acceptance. In addition, encourage them to take the documents home for discussion with family members. Support from outside of the workplace is a very strong motivator in work-centric safety programs.

Car crashes are the number one cause of workplace fatalities (On The Road, n.d.). No job task, no matter how seemingly important in the moment, is worth the price of a human life. Diligently enforcing your company’s distracted driving policy, without exception for key members or key roles, will ensure eventual acceptance and integration into your company’s safety culture.

INTERDEPENDENCE CFACON22 EDUCATION

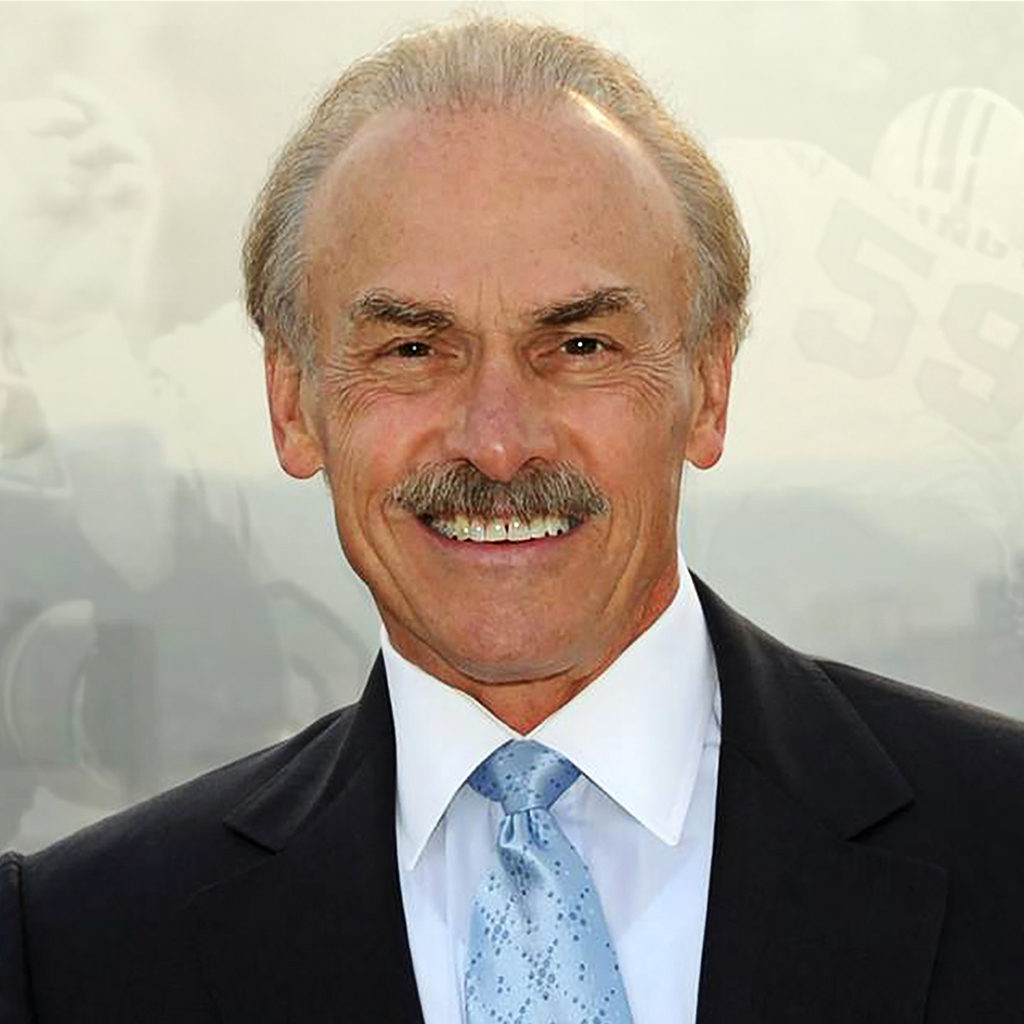

FEATURED KEYNOTE:

ROCKY BLEIER

Vietnam Vet and Four-Time NFL Super Bowl Champion. Rocky Bleier’s life story – a gripping tale of courage on both the football fields of America and the battle fields of Vietnam – has held audiences in rapt attention for years. Yet, the motivational message behind it, detailing how ordinary people can become extraordinary achievers, defines success in the new American century.

“Admittedly, I’m not a sports guy…so I was not sure what to expect when going to hear Rocky Bleier for the first time. I’m happy to say, that his story is so inspiring! I walked away not only encouraged but inspired to think big, and challenged to not make excuses. I’m now a huge fan of Rocky Bleier and I’m excited to hear him again!” – Jason Ells, Sr Vice President, Custom Concrete.

__________________________________________________________________________

FEATURED PRESENTER:

CONNOR LOKAR

Senior Forecaster for ITR Economics. Few young economists present their insights with the authority, accuracy, and humor that Connor Lokar brings to the stage. Few young economists present their insights with the authority, accuracy, and humor that Connor Lokar brings to the stage.

“He knows his stuff and presents it well. More important to me, he

flexes the conversation and presentation based on who’s in the group and where the conversation leads. That is a great asset that seems to flow from him naturally. I wish it were true of more speakers.” –

Gil Herman, Vistage Chair, Chicago, IL

__________________________________________________________________________

WORKFORCE DEVELOPMENT:

Growth Cultures, Hiring Systems and Hiring Inspiration. In what ways are you challenged to achieve success as the ideal employer in your market? Every employer in North America faces the unprecedented challenge of attracting employees to the deficit of a quality workforce. Construction couples this with the generational indifference to hard work…or does it? Participate with JASON ELLS of Custom Concrete as he focuses on advancing a Growth Culture in a presentation about consciously evolving and improving your company culture to establish the best platform for attracting and retaining top talent. Participate with

DOUG HERBERT of Herbert Construction as he delivers Hiring Systems with a presentation looking at the need for intentional hiring systems and how to evaluate their importance. Further clarify and qualify with DAVID WHITLOCK, ESQ with his Hiring Inspiration presentation that helps you determine how to do enough to comply without creating obstacles by overdoing the hiring process.

__________________________________________________________________________

FOUNDATIONS EXPOSITION & PRODUCTS SANDBOX

A unique take on outdoor exhibits that have been a signature moment in past conventions, this year many exhibitors will be offering Interactive displays to learn more about the application of their products, services and equipment to your business. Get your hands on this technology in ways you cannot at World of Concrete and determine what is your next CapEx commitment or the newest innovation to give you a leading edge.

INTERDEPENDENCE CFACON22

ACCOMMODATIONS

The Westin Boston Seaport District

425 Summer St., Boston, MA 02210

The CFA has reserved a block of rooms with a special rate of just $269/night at The Westin Boston Seaport District. Less than three miles from Boston Logan Airport, this hotel is ideally located in the vibrant Seaport District, just steps from downtown attractions. Rapidly becoming a popular attraction among visitors, and already a favorite of Boston locals, the Seaport District offers a variety of experiences for any age. Enjoy a stroll along the waterfront, shop for a treasured souvenir, sample the cuisine and explore the Institute of Contemporary Art’s collection of masterpieces. If you are looking to extend your stay, discounted rates will be available July 4-12th. The room block and rates will expire in June, so be sure to book early! Reserve your room at bit.ly/CFACON22 today!

EXPERIENCE BOSTON

Signature Lunch Cruise on the Spirit of Boston

Guests Only | Friday, July 8, 11am – 2pm

Back by popular demand, the 3rd Annual Guest Social will take place Friday afternoon while business attendees are deep into education. Bring your family and/or special guest to the event and sign them up to experience a lunch cruise on Boston’s favorite yacht, the Spirit of Boston. Boarding will begin at 11am right in the Seaport District, and guests will enjoy a 2-hour cruise on the Boston Harbor. Included is a delicious lunch buffet with freshly prepared entrees, salads and desserts, drinks, onboard entertainment, an open-air lounge for games and relaxation, and the absolute best views of the Boston skyline and iconic waterfront landmarks – There’s no better way to see the city than from aboard the Spirit of Boston!

BOSTON HISTORY

The Boston Tea Party Ships and Museum

Friday, July 8, 6pm – 8pm

Directly following Happy Hour in the exhibit hall, the CFA is taking you and your family to one of Boston’s most popular areas on Friday evening of this year’s event – The Boston Tea Party Ships and Museum. Guests will enjoy food and drinks while networking on Griffin’s Wharf, and have the opportunity to travel back in time to 1773 and re-live the battle and events and see fully restored replicas of the ships throughout the evening – Come experience the Boston Tea Party Ships and Museum like never before!

CATCH A RED SOX GAME

Yankees @ Red Sox – Fenway Park

Saturday, July 9, 7:15pm

The CFA is excited to announce that we have reserved a private space inside of one of Boston’s most iconic landmarks, Fenway Park, for this year’s closing social. Tickets are limited to the first 100 people to register for the closing social. While the Boston Red Sox take on the New York Yankees, guests will enjoy access to our private space, an all you can eat 2-hour BBQ buffet, 4 hours of open bar which includes beer, wine, soda, water and snacks, and unparalleled views of the field. Tickets are limited and very popular, be sure to register early for this year’s closing social!

#CFACON22: BOSTON, MA

Janette Barr Retires After 25 Years

How does one mark the end of an era? Phrasemix.com offers that an “era” is a period of history in which something important happens. An “era” usually lasts for a long time: hundreds or thousands of years. Some examples of well-known eras are: The Victorian era (in Britain in the 1800’s); The Cold War era (from the 1950’s to the 1980’s); the Golden era of ___; or the Modern era. This site further provides that, when an important event happens, you can say that the event “marks the end of an era” or “marks the beginning of a new era”, such as Americans hoped that the election would mark the beginning of a new era for the country. In this context, the use of the term “marks” is used symbolically to indicate or signal the ending or beginning of an era.

It is with this symbolism that the Concrete Foundations Association marks the end of the most significant era in its history. That era is one beginning in 1997 and ending March 15, 2022, with the official retirement of Janette Barr.

“When I first hired Janette, she didn’t have much experience, but she was a fast learner. I immediately took a liking to her sense of humor,” states Ed Sauter, CFA’s Executive Director from 1994 to 2016. “She had a good rapport with most of our association members and I could often overhear her laughing as she conversed with them.”

Janette inquired about an open position in the fall of 1996 and officially started January of 1997. At that time, the Association resources consisted of a small, bi-monthly newsletter, an annual conference, and a gathering during the World of Concrete. Communications were mostly by fax, phone and mail and membership was processed solely by company check.

After a brief period of transition when a family move took her away and brought her back to Mount Vernon, IA where the Association headquarters were located, she found her way back to the frontlines for members. “We had several more secretaries/office managers after she left but none of them fit in as well as Janette, offered Sauter. “Janette later returned to the area but worked for another business since we had hired someone. Subsequently, the person we had hired wasn’t a good fit and Janette wasn’t happy where she was at. The two secretaries knew each other and proposed that Janette come back to work for us.

She has been holding down the office ever since that return in the latter part of 1998. During this time, the Association has experienced unparalleled evolution. Membership has waxed and waned through the roaring part of the 2000s, the crippling Great Recession and the return to growth of recent years. Resources have exponentially grown with numerous manuals and technical products, websites, marketing flyers, and business programs to benefit the member organizations. Events have multiplied with the addition of business courses, regional meetings, certifications and many more. In addition, the outreach of the Association has extended from purely a member-based network to a voice for the industry as most reading this article now benefit in a free subscription and numerous electronic communications throughout the year.

“When I stop to consider how this Association was managed in the late stages of the last century to what it is now I can hardly believe the challenges she has faced,” states James Baty, CFA’s current Executive Director since 2017 and a part of the management team since 2001. “Janette has managed the Association across four transitions in data management in addition to all the resources, transactions, communications, and schedules. She has learned, relearned and taught many new faces these systems.”

Sauter perhaps says it best when he offered, “Janette was easy to talk to, always asked about the family, and her presence will be missed.” It is hardest to end an era when you actually see it ending. Most are concluded and pronounced by historians well after the fact. Janette is wished the very best as she now transitions to a focus back fully on family and the many rich areas of her life interests. Congratulation cards and messages can be sent to Association headquarters at PO Box 204, Mount Vernon, IA 52314.

Soil Connect Marketplace Curbs Rising Fuel Costs by Finding Materials Closer to Where They Are Needed

As fuel prices soar, contractors are finding help controlling costs online, with the Soil Connect marketplace. This industry leading platform helps contractors find soil and aggregates closer to where they are needed, thus saving fuel and time, while minimizing their carbon footprint. Award-winning Soil Connect dirt and aggregates marketplace uses matching algorithms to create close connections between people who have material and those who need material. With average fuel prices over $4 per gallon and rising, every mile eliminated equates to money saved. Early knowledge of the supply and demand dynamics of soil and aggregates has enabled users to achieve substantial savings in fuel and material costs, often reported in the thousands of dollars. The site is free to use and can be viewed at www.SoilConnect.com and is available as an app from Google Play or Apple.

“Soil Connect was built to serve the construction ecosystem and saving on fuel costs by finding closer materials clearly illustrates how users are benefitting from the technology,” said Soil Connect Founder Cliff Fetner. “In addition to driving fewer miles, users shorten cycle times, and bolster productivity. All of these enhance project efficiency and strengthen the bottom line.”

Besides the Soil Connect Marketplace, the company offers eTickets, an e-ticketing platform to improve efficiency and alleviate the administrative burden of handling paper tickets. With eTickets, customers can easily track loads, capture photos of the materials, and obtain contactless signatures. An eRegulatorySM tool which provides customers with the first ever online method to digitally capture and track all required documents (such as State Manifests), is also available. In addition to the compliance form, the patent-pending eRegulatorySM product includes turn-by-turn tracking of loads with both a map view and printed list.

For more information on the Soil Connect Marketplace, eTickets, or eRegulatorySM, visit www.SoilConnect.com.

About Soil Connect

Soil Connect is the first and only institutionally backed digital marketplace focused on the multi-billion-dollar soil and aggregates industry. The marketplace was created to solve the high costs and inefficiencies associated with the transport and management of soil, aggregates and other materials. Founded by third-generation builder and developer Cliff Fetner, the app connects those who have soil and aggregates with those who need it. The marketplace offers a seamless and streamlined solution for excavators, contractors, developers, landscapers and other building professionals to network and transact with one another while saving time and money and positively impacting the environment. For more information, please visit www.soilconnect.com.

YOUR ADVANTAGE IN THE MARKETPLACE

The following articles are excerpts of important topics and research information. Full content is made available to CFA members through the website you will access with the QR Code following each piece. Note: If you are already logged in, the code will take you directly to the article. All article content will also be available from the member landing page. These articles are contributed by our resource partnerships to advance your advantage in the marketplace, plan based on industry influences, or challenge your practices and processes.

For more information on CFA membership, please contact Skye Kelley, skelley@cfaconcretepros.org or visit us at www.cfaconcretepros.org/join-us.

______________________________________________________________________________

This article is provided by ITR Economics in partnership with Concrete Foundations Association.

RECORD RETAIL ACTIVITY

Annual US Total Retail Sales (deflated) are rising at the fastest pace in the 74-year data history, up 13.9% from 2020. Strong consumer trends – including a low debt-to-income ratio, elevated savings to tap, and low unemployment – are contributing to record-high Retail Sales. Despite rising US Consumer Prices (up 7.5% over the last 12 months), consumers have thus far been willing and able to swallow increased costs. With record-high Retail Sales comes the inevitable need for expanded capacity, both for the production and transportation of goods. Some snags, however, are impacting the movement of goods, and we expect such problems will persist in the coming quarters.

RECORD SHORTAGES OF WORKERS

The unprecedented labor shortage is a significant impediment to our ability to move goods around the country. Annual average US Total Transportation, Warehouse, and Utilities Job Openings are 50% above the pre-pandemic record high. In contrast, US Total Nonfarm Job Openings are up 34%.

For the trucking industry, labor shortages are nothing new. For years, transport services have struggled to fill job openings and expand capacity to meet rising demand. There are several factors at play:

Existing truck drivers are reaching retirement age.

New truck fleets include more technology to which drivers must adapt, along with new regulations and safety standards.

Unappealing hours and time spent away from home factor into many trucking jobs.

While employers have used every tool at their disposal to attract new drivers – including higher wages, better benefits, and bonuses – the shortage has held.

For the complete article:

______________________________________________________________________________

This article is provided through the PR/PR Public Relations partnership with Concrete Foundations Association.

CONSUMER INSIGHT IS CRUCIAL TO CLOSING A COMPLEX SALE

By Jill J. Johnson, MBA

A sale is classified as complex when it involves a high degree of risk and uncertainty and when the process involves more people than just the final consumer. As more people are involved in a sales decision, the sale becomes more complex.

Complex sales are not resolved in one single interaction. When there are multiple decision points, the real goal is to keep the conversation moving forward toward the next decision. Recognize there are competing goals at play, too. Your goal is to make the sale; their goal is to make the right decision based on their wants, needs, and budget. Your prospect also might be considering competitive offerings, so keep the conversations going about you and what you offer.

PSYCHOGRAPHICS DRIVE BUYING BEHAVIOR

In target marketing, there are eight different major variables you can use to define your target audience. When you are looking at a complex sale, the most critical component to understand is the psychological make-up of your prospect. This is referred to as the psychographics of your customers. What drives them and what drives their buying behavior?

DECISION TRIGGERS MOVE SALES DECISIONS

After you gain a foundational understanding of your consumer’s characteristics during a complex sales process, you need to find out what will trigger your consumer to make the final decision to purchase your product or service. Whatever decision triggers might influence your prospect, be sure you address them in your sales presentation.

For the complete article:

______________________________________________________________________________

This article is provided through the PR/PR Public Relations partnership with Concrete Foundations Association.

SIX WAYS TO GET REAL WITH YOUR EMPLOYER BRAND

By Jeremy Eskenazi

Employer branding is the external perception of what it’s like to work at your company. It has always existed in some form, but recently, it has not only become more planful, but it’s also become a lot more important. Employees always have choice, let’s remember that first. It means that if the experience of working at your company is not good, they have as much ability to leave as you do to end their employment. It will likely be a lot easier for them to find a new role than it will be for you to replace them, and their experience does not end when they leave. Employees are your most important source of distinguishing your employer brand – both positively and negatively.

A manufactured employer brand is very easy to spot – it’s high polish, very diverse, and has a lot of smiling people. This may be false representation, but where a lot of creative agencies have made their money. Fast forward now to Employer Branding 2.0. Nobody is buying the lie! Employer Branding 2.0 starts with authenticity and transparency of what it’s really like to work at your company.

To help avoid costly recruiting cycles, or a lack luster pipeline of interested candidates because people are reading or hearing that working for your company is terrible, remember that employer branding has a very long reach. Here are the six top ways to get real with your employer branding (if you care about things like retaining your top people and attracting more who can knock it out of the park!):

For the complete article:

______________________________________________________________________________

This article is provided by MatchBuilt an industry resource for recruitment strategies and consulting as an offer to members of the Concrete Foundations Association.

TOP RECRUITMENT STRATEGIES FOR

CONSTRUCTION COMPANIES

By Mark Matyanowski

The pandemic exasperated an already significant shortage of skilled construction workers at nearly all levels, and construction companies’ recruitment strategies have never been more critical. Brent Darnell International (www.brentdarnell.com), a company that teaches emotional intelligence in construction, has even said that there’s a “war for talent” now in the construction market.

The Home Builders Institute suggests that 740,000 new construction workers are needed each year for three years to account for attrition. “The construction industry needs more than 61,000 new hires every month to keep up with both industry growth and the loss of workers either through retirement or simply leaving the sector for good,” said Home Builders Institute CEO Ed Brady. “From 2022 through 2024, this total represents a need for an additional 2.2 million new hires for construction, and that’s a staggering number.”

With this in mind, we’ve crafted this guide of the top recruitment strategies for construction companies, and we’ll take a step-by-step look at how you can put the odds in your favor. Let’s see!

Step 1:Build Your Brand for Better Communication

Step 2: Source the Best Qualified Employees

Step 3: Crown Your Efforts By Interviewing the Right Way

Step 4: Offer Continuous Training for Your Newly Hired Employees

The Concrete Foundations Association will offer three specific presentations during #CFACON22 in Boston this July that address the importance of Culture, Hiring Systems, and Definition of Expectations to drive the growth needs of organizations. For more information, visit the event calendar at www.cfaconcretepros.org.

For the complete article:

World of Concrete 2022 Wrapped a Highly Productive and Well-Attended Event, Fueling Industry Connection and Advancement

Nearly 37,000 construction and masonry professionals convened in Las Vegas this week for peer-to-peer connection, deal-making, education, and competition.

Las Vegas, NV (January 21, 2022) – World of Concrete, Informa Markets’ premiere exhibition serving the thriving construction and masonry industries, concluded the event’s 47th annual event held this past week – Expo, January 18-20; Education, January 17-20 – at the Las Vegas Convention Center (LVCC). Convening close to 37,000 registered professionals, the consistent foot traffic in the expo halls, high engagement with the comprehensive educational offerings, and overall vibrance exuded from participants underscores the industry’s critical need for in-person connection.

World of Concrete took over 632,000 NSF of the expansive and newly expanded LVCC, hosting over 1,100 industry-leading suppliers in the expo hall, just over 150 of which were first-time exhibitors, offering attendees a wide range of brands to explore from the most sought-after global enterprises to niche SMBs spanning a variety of applications.

“The level of engagement from companies of all sizes and corners of the industry was very encouraging, especially following the past couple challenging years, and points to the revival of the trade show industry and continued growth of the construction and masonry sectors,” remarked Jackie James, Group Director, World of Concrete. “We are thrilled with the positive feedback we’ve received from our community, buyers and suppliers alike, and look forward to seeing a wealth of new business partnerships and industry innovation resulting from this week’s event.”

In addition to a robust expo floor, registered participants had the rare opportunity to engage with world class education made available at the must-attend event. World of Concrete’s coveted educational programs serves as an incubator for knowledge sharing and technical know-how, helping the industry overcome challenges and tap into new opportunities for growth. With more than 11,000 expert-led sessions, this year’s highly curated education explored a balance of technical and forward-looking topics, ranging from 3D printing in concrete construction, women in construction, waterproofing: the next generation of solutions, and much more.

James continued: “Year after year, industry professionals flock to World of Concrete for its highly regarded education and the unique opportunity to garner technical certifications to help professionals

navigate this complex industry. This year was no different; we were pleased to see meeting rooms packed with engaged attendees bouncing ideas off peers – it is admirable to witness this industry’s continued ambition to grow and share ideas.”

Not only does the industry gather at World of Concrete’s annual event for deal-making and education, but to see and demo the most cutting-edge products available on the market and see the latest industry developments that lay the groundwork for the coming year. Trends from the 2022 event include, but are not limited to:

Greater job site productivity, with new battery systems that deliver more power to the hand tools used to perform demanding concrete tasks, such as drilling, cutting, and demolition;

Introduction of equipment that is automating concrete construction activities, including 3D printing, rebar tying, and drilling overhead holes;

Entrance of new materials that increase contractor productivity while still ensuring durable repairs;

Streamlined management data management systems that enable contractors to tighten a project’s critical path;

And product and equipment updates that reduce a project’s carbon footprint and increase contractor productivity.

Returning for the 17th consecutive year, The Concrete Industry Management (CIM) program held its Silent & Live Auctions, generating an all-time record of more than $1,740,000. Donations originated from the live auction and online contributions, marking a historic moment in the program’s rich history at World of Concrete that is designed to give students entering the concrete workforce industry experience early in their careers. World of Concrete is proud to partner with the CIM program, a business program

developed specifically for the concrete industry to provide students with a four-year Bachelor of Science degree in Concrete Industry Management.

Published on the front page of the Las Vegas Review-Journal for its exciting and action-packed competition, the 2022 edition of the ever-exciting SPEC MIX BRICKLAYER 500® World Championship crowned Mason Cole Stamper as the “World’s Best Bricklayer,” along with his mason tender, Jeff Becker. The two took home top honors and bragging rights, in addition to a new Ford F250 4×4 truck and more than $10,000 in cash and prizes. Scott Tuttle and mason tender Brian Tuttle locked in the second most coveted award at the event, the SPEC MIX TOP CRAFTSMAN, laying 730 brick in one hour. Their remarkable effort won the Tuttles a new Kubota RTV-X1140, plus more than $10,000 in cash and prizes. For complete results of the 2022 SPEC MIX BRICKLAYER 500® competition and images from the event, visit here.

New this year and central to World of Concrete’s core values, the exhibition organizers formalized the event’s commitment to sustainability in collaboration with renewable energy partner/sponsor HILTI. The program was intentionally executed with three objectives: Inspiring Sustainable Development, Environmental Responsibility, and Social Responsibility – each pledge supporting the event’s commitment to shaping the concrete industry for a sustainable future. Thanks to HILTI’s Renewable Electricity sponsorship, World of Concrete’s electricity use is powered by sustainable and renewable energy sources, saving an estimated 204 tons of CO2e.

Media Contacts

Lauren Lloyd, PR Director,

310-266-4792, lauren.lloyd@informa.com

Abby Portwood, PR Specialist

213-544-7275, abby.portwood@informa.com