How Do We Stack Up?

If your company is like mine, right now you see everything turning up. The weather is turning and the forecast for Spring is starting to look real. We see jobs breaking and more pushing toward our involvement. Better yet, we know the struggles that have been faced over the last four months are all but gone and we can return to working at a straight pace with consistent product, conditions and contracts.

But is your company also like mine, with family members involved with you, even the next generation beginning to desire involvement? Can you foresee the problems coming in ramping up the labor force to handle the increased workload because the job market is saturated by unmotivated and “entitled” persons? Are you finding it a challenge to determine the best way to cycle out or recycle some of your overused equipment, the things you’ve been making due with and have held on to far to long? There is a pretty good chance that involved in this industry you can say yes to most of these questions in some way or another. What I know is there isn’t that much different between our companies, except perhaps one big one. We’re a member of this Association.

Having missed out on World of Concrete this year, I’m really looking forward to what this summer brings. Our convention will take place in a spot I know my family is looking forward to visiting and I’ve seen that some of the answers to my questions above are planned in the education that will be offered. As owner of this company, I draw a lot of my strength from the conversations and the network access I have found here. It isn’t always easy and there are some tough decisions that have to be made in order to achieve consistency when it comes to knowledge and experience. But that is on me, the peers I’ve met and continue to meet new each and every month through the CFA have become some of my most valuable assets.

It is also now March Madness and before you let the madness of the construction season grab a hold of you, let me just encourage you to set two calendar dates now. One date needs to be set immediately to join the CFA. It is the best $600 investment you will every make in your company. The other date is July 23-25. CFA Convention is the largest annual and dedicated gathering of the cast-in-place concrete contractor industry. I’d like to meet you, introduce my family and my fellow members, my friends to you and most importantly learn from you.

David Martinson – Martinson Construction

“Damp Rising”

As published in Concrete Contractor Magazine.

Question: I have a homeowner that wants me to put a poly sheet over the footing before I begin forming the foundation wall. He has read that water can migrate up through the footing into the wall and create mold problems for his home. Is this accurate? I’m concerned about the connection of the wall to the footing.

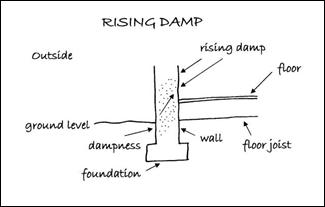

Answer: One of the current en vogue issues in the residential concrete industry by owners and designers is that of a phenomenon known as “rising damp.” This condition, described as the transportation of sub-grade moisture surrounding a house foundation through the footing and concrete wall and into the living space, has become a frequent technical inquiry at CFA headquarters.

“Rising damp is a European phenomenon produced from stone and block foundations rendered with stucco or plaster,” states Brent Anderson, P.E. of BDA Associates in Minneapolis, Minn. “Those foundations are tremendously hydrophobic, and permit large volumes of moisture to enter from the surrounding soils. They naturally move toward the warmer, dryer condition of the living space and then affect the adhesion of the plaster to the structural wall. Owners then have to remove the failing plaster and reapply, only to see the same thing happen in a few short years.”

Anderson, a long time champion for the quality of residential concrete, presented the subject of waterproofed concrete during the ACI 332 – Residential Concrete full committee meeting in Washington DC last fall. In attendance were many CFA contractors volunteering their time to help direct intentional transition of smarter codes and standards for residential concrete.

“It would take approximately 4,000 years for water to move through six inches of properly designed and delivered concrete,” notes Anderson. “Therefore, where is the concern for rising damp in today’s U.S. residential market? The best things that ever happened to residential concrete are the concrete pumps and conveyors. The design of concrete to take advantage of their efficiencies delivers an exceptional mix design to your footings and walls. It then becomes an issue of ensuring the natural cracks that happen in concrete are controlled (proper reinforcement) and/or the water prevented from reaching those cracks (effective waterproofing system).”

You should take caution when considering placing a poly sheet as a barrier between the footing and wall. This sheet can place the foundation wall at risk for movement during backfill, if it is not properly braced. ACI 332 requires all foundation walls to be connected to the footing either by a dowel at 24-in. on-center or a keyway. If the wall is doweled to the footing, the moisture barrier theory cannot be 100 percent effective due to the perforations, assuming it wouldn’t tear during forming and removal in the first place. Instead, a better recommendation is to work with your customers to help them see the complete system that actually controls moisture infiltration beginning with the quality of your concrete. If the concern remains, a spray-applied membrane that contains an aggregate for surface roughness would be a far better suggestion, although this would be a suspender to an already strong belt.

Jim Baty is the Executive Director for the Concrete Foundations Association after having served as Technical Director since 2001. He is currently chair of ACI 332 and a voting member for ACI 306 with priorities of establishing better guidance and structure for residential concrete construction. For more information on this topic, contact Jim Baty at jbaty@cfawalls.org. Find out more at www.cfawalls.org.

For Sale: Used 9-ft Western Flagship Elite

This equipment is being offered for sale by a CFA member in Ohio.

For sale is a used set of 9-foot, Western Flagship Elite forms. This is a complete set with many fillers, baskets, pinlocks, hinges and more. Review the complete inventory list for more details.

Contact Matt at (419) 286-2086 for more information, condition and pricing interest.

Monarch Materials Group Names New President

January 19, 2015

ADEL, IOWA – Monarch Materials Group names new president.

Monarch Materials Group, Inc. (Monarch) named Dan Higgins as its new president today. Monarch manufactures residential, basement window egress systems in Adel, IA and Englewood, CO and distributes them throughout the United States.

Dan joins Monarch having extensive experience in the concrete construction industry. His industry experience began as a regional sales manager with ConSpec Marketing and Manufacturing in Kansas City, KS. He also served in multiple roles for Dayton Superior Corporation, a manufacturer of a broad range of concrete construction products and services. Most recently, Dan was with a Pella Window & Door distributor as general manager and director of sales. Prior to this experience, Dan was with Pella Corporation helping lead business development.

Dan is a veteran who has served multiple combat tours in Afghanistan and Iraq. He has a Bachelor of Science Degree in Civil Engineering from the United States Military Academy at West Point, NY and a Master’s Degree in Business Administration from Rockhurst University in Kansas City, MO.

Dan and his family currently reside in Pleasant Hill, IA.

A Day in the Life of a Leader

CFA Professional Awards

CFA RECOGNIZES MARY WILSON OF MICHEL CONCRETE WITH M.V.P. AWARD

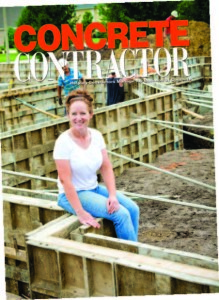

Cover from Concrete Contractor Magazine’s June/July 2011 issue featuring the diversification efforts of Mary Wilson and Michel Concrete.

Sonny Newman, president of contract manufacturer EE Technologies was quoted in Business News Daily in defining leadership as “influencing others by your character, humility, and example. It is recognizable when others follow in word and deed without obligation or coercion.” This quote is a perfect representation of the parameters considered when the CFA Board of Directors awarded Mary Wilson of Michel Concrete in Springfield, Illinois the Most Valuable Person award this past summer.

The CFA M.V.P. award was developed to recognize the significant contributions of specific individuals toward the advancement of the Association’s mission and purpose. This award was first presented in 2004 to Brad Barnes, P.E. for this leadership and authorship of the ‘CFA Cold Weather Research Study and Final Report’. Brad passed away this past year leaving behind a legacy of confidence in the performance of concrete walls during cold and freezing conditions. Current CFA President, David Martinson of Martinson Construction in Waterloo, IA states, “In short, this M.V.P. Award is presented to an individual who has given generously of their time and talent in helping the CFA become the successful organization that it is today.”

It is likely that Mary’s name is not unfamiliar to you. She has been extensively involved in much the CFA has been about over the past six years since joining in 2008. Nearly as soon as she brought her company into the CFA network, she began taking on the challenges presented to her. Much of this has come in the way of asking questions of interest and finding new ways to express or challenge both her answers and those of her peers. This has included becoming a Board member, a voting member of ACI Committee 332, chair of ACI 332-D for Footings and Foundations and much more.

Mary is perhaps most widely known and recognized for her work on the CFA’s interpretation for fall protection. At a time when OSHA was turning the entire residential construction industry toward one of six active fall protection systems (safety nets, lanyards, guardrails, ladders, aerial/mechanical lifts and scaffolds), she forged ahead with three months of extensive research recognizing the stress and risk these systems would place on her crew members, most notably scaffolding. Her efforts resulted in the CFA’s production of a draft alternate fall protection position, an educational program on how to determine the impact of fall protection systems and their feasibility and later sponsored the creation of an entire development program for contractors the CFA now offers to its members.

We congratulate and thank Mary Wilson for her unselfish, humble and dedicated leadership to carve a portion of a stronger future for this industry.

Mary can be reached at Mary@Michelconcrete.com.

The CFA Projects of the Year Competition

EACH YEAR, PROFESSIONALS IN THE CONCRETE INDUSTRY THAT ARE MEMBERS OF THE CFA SUBMIT PROJECTS OF VARYING SIZE, SCOPE AND CHALLENGE FOR CONSIDERATION BY THE GENERAL PUBLIC TO BE CONSIDERED AS A PROJECT OF THE YEAR. MULTIPLE CATEGORIES OFFER RECOGNITION FOR ACCOMPLISHMENTS OF ANY SIZE AS WELL AS TYPE OF PROJECT.

The 2014 Grand Project was selected by industry peers and popular vote to be the serpentine walls of the Gardenesque home built in Madison, WI by CFA member, Hottmann Construction.

This year, ten projects are presented on the pages that follow. Each page gives key statistics and a brief synopsis of the project from perspective of the submitting company, as well as some representative photos.

As a participant in this industry, you are encouraged to visit the CFA Projects of the Year at http://bit.ly/CFAAwards or by visiting the CFA website, www. cfawalls.org.

You will be presented by each project, with multiple photos and additional project information. Each project will be rated on a scale of 1 to 5 (not ranked) according to three categories of assessing its challenge and success.

All projects will be evaluated for top project in each category, honorable mention. One project will be selected across all categories as the Overall Grand Project.

Year after year, companies with entries receiving such recognition make this a part of their marketing presence. If you have projects that have presented challenge or offer a sense of pride for your company, you are encouraged to consider submitting them for next year’s competition.

Contact CFA Executive Director, Jim Baty, at jbaty@cfawalls.org or 866- 232-9255 to discuss the competition in detail.

Each project submitted for the 2015 competition can be visited at http://www.cfawalls.org/awards/project/index.html where a unique link to the voting will also be made available until midnight on February 28th, 2015. Winners will be presented during the Annual Convention in Williamsburg, Virginia this summer and throughout the CFA website.

CFA Members Exhibiting at WOC 2015

The Concrete Foundations Association is a co-sponsor for the World of Concrete. We are also an information and network hub for a vast amount of education and information available in seminars and throughout the show floor. Interested attendees can register at the lowest attendance rates for WOC through the CFA and our unique link of http://bit.ly/WOCwithCFA. Be sure to visit the CFA WOC2015 booth at #C4341.

See these CFA member companies and many more at World of Concrete 2015, Feb. 2-6 in Las Vegas, NV.

*New for this year, an exhibit-only pass will be available at a $20 fee (no free passes offered) Online registrations only. Valid for new registrants only. Some restrictions may apply. Contact CFA or Hanley Wood, show owner, for more details.

BIK Hydraulics……………………………………………C4709

Boman Kemp…………………………………………….N2244

Concrete Contractor Magazine……………………C4129c

Concrete Forms Services LLC……………………..O32019

Cosella-Dorken Products Inc……………………….O32125

Cranes & Equipment Corp………………………….C6425

Epro Services Inc……………………………………….S11254

GMX Inc…………………………………………………….S10752

Grip-Tite Manufacturing Co LLC…………………..S10847

Helix Steel…………………………………………………N312

Hiab USA Inc……………………………………………..C5921

Irving Equipment LLC…………………………………C5447

Leica Geosystems Inc…………………………………C5748

Mar-Flex Waterproofing & Building Products…C3649

North American Specialty Products……………..N2562

Nox-Crete Products Group………………………….S11219

PALFINGER North America…………………………C5803

Precise Forms Inc………………………………………C4519

Prinsco Inc………………………………………………..N1557

Putzmeister America Inc……………………………..C5727

Rockwell LLC…………………………………………….N2057

Schwing America……………………………………….C5126

SpecChem LLC………………………………………….C3245

Stego Industries…………………………………………S11650

The Bilco Company……………………………………N1051

Thermomass……………………………………………..C4148

Tremco Barrier Solutions Inc……………………….S10827

Wall-Ties & Forms Inc…………………………………C4611

Western Forms Inc……………………………………..C6127

Cold Weather Slab Testing

EARLIER THIS YEAR, A CONTRACTOR AND A TEAM OF MANUFACTURERS AND INDIVIDUALS, PERFORMED A SERIES OF COLD WEATHER TESTS ON 15 DIFFERENT PANELS TO REPLICATE 15 DIFFERENT FIELD CONDITIONS. HERE ARE THEIR PRELIMINARY FINDINGS.

As seen in

Earlier this year, a contractor and a team of manufacturers and individuals, performed a series of cold weather tests on 15 different panels to replicate 15 different field conditions. Here are their preliminary findings.

In the course of conducting cold weather testing on concrete slabs, Dennis Purinton, owner of Purinton Builders in East Granby, Conn. and his team, which included five ACI 306 Committee members, were seeking answers to the following questions:

• What effect does cold grade and cold ambient temperature have on slabs on grade?

• Does changing concrete temperature change its performance?

• Does concrete temperature affect the performance of accelerators?

• What effect do Supplemental Cementitious Materials (SCM’s) have on cold weather slabs?

“It was a great winter for field testing the performance of slabs on grade in cold temperatures,” says Dennis Purinton, owner of Purinton Builders in East Granby, Conn.

The team chose February 10, 2014 as the placement day and it was a beautiful, cold day in Suffield, Conn. Purinton says the morning started with single digit temperatures and a couple of inches of new snow from the night before. Meanwhile, the ambient temperature never got above the mid 20s.

THE TEST

The testing consisted of 15 different 10 foot by 10 foot by 5 inch panels that replicated 15 different field conditions. “We placed three loads of concrete, provided by Tilcon, Conn. Two loads were a straight Portland cement design,” says Purinton. “The only variable was its batch temperature. The third load was a ternary blend of 45 percent SCM’s.”

Two of the 15 panels were constructed in a temporary building that had cold subgrades. A Wacker Neuson indirect fired heater was utilized here.

The balance of the slabs were placed outside in the open air; some with cold sub-grades, some utilizing hydronic ground heaters to heat the bases, and one with two inches of XPS directly under the slab.

All 15 panels were monitored with Con-Cure radio remote maturity meters. “There were four probes in every panel,” he says. “One was placed two inches below grade, one at the interface of the concrete and base, and two in the slab. We also monitored surface temperatures with a hollowed out block of insulation and a digital thermometer.”

The time of concrete placement and the surface temperature of the concrete were recorded at every step in the finishing process. In the slabs utilizing higher temperature concrete, the surface temperature dropped as much as 12 degrees Fahrenheit during the finishing process. In the slabs utilizing the lower temperature concrete, the surface temperature dropped as much as 15 degrees Fahrenheit. Even with surface temperatures dropping, no finishing issues occurred.

An ACI certified lab technician was also on site to record concrete temperature, test for air content, and make cylinders to be cured at the lab and tested for compressive strength.

After the finishing process was complete, all panels were covered with poly and blankets. “In addition, we added hydronic heat piping on top of the poly and under the blankets in three of the panels, to simulate moist, heated curing environment,” Purinton says.

CORING THE SLABS

During the seven days after placement, the average ambient daily high temperature was 29 degrees Fahrenheit. The nights averaged 13-degrees Fahrenheit with a low of zero degrees. Two days after placement, a 12 inch snow storm walloped the area of placement.

On the eighth day, the maturity meters were removed for reading, along with the blankets and poly on all panels. Water was present under the plastic on all panels, including the edges and corners. The surface temperature of all slabs was still above 32 degrees Fahrenheit despite only a few hours of temperatures above 32 degrees Fahrenheit over the previous seven days.

“We cored all 15 slabs at eight days and again at 28 days,” he explains. “The cores were taken to the Connecticut-based, Materials Testing, Inc. and tested for compressive strength.”

OBSERVATIONS

The following are just a few of the interesting facts that were observed in the testing process:

• There was minimal drop in the concrete temperature where the interface of the concrete and the 33 degree Fahrenheit sub-grade met.

• The 33 degree Fahrenheit sub-grade temperature had little or no effect on the concrete two inches above sub-grade.

• The sub-grade absorbed heat from the initial hydration that was slowly consumed by the slab in the curing process over some number of days.

• Two inches of XPS directly under the concrete accelerated set and finish times and reduced the compressive strengths in the cores.

• A warm sub-grade will shorten finish time, but higher concrete temperature will reduce finish time even further.

• Two trucks of the same mix design were ordered. The only difference between the two was the concrete on the first truck was 88 degrees Fahrenheit, while the concrete on the second truck was 54 degrees Fahrenheit. The 88 degrees Fahrenheit concrete compressive strength in lab cured cylinders was over 20 percent less than the 54 degrees Fahrenheit concrete cylinders. The cores in the field panels showed a similar reduction in compressive strengths.

• Finish times for the 45 percent ternary blend mix design showed a 10 percent increase in comprehensive strength over a 53 degrees Fahrenheit Portland cement mix design, and over 30 percent higher than the 88 degrees Fahrenheit Portland cement mix design. All were cured under the same conditions.

• Non-chloride accelerators are temperature sensitive in their effectiveness on finish time.

Purinton says the amount of data collected from this cold weather slab testing was daunting, resulting in hundreds of possible performance comparison combinations. “We have just begun in the effort to draw conclusions to many of these comparisons.”

Editor’s Note: None of this testing could have been carried out without the valuable help received from many companies and individuals. Thanks to Mike Barry; Gene Daniel; Euclid Chemical Company; Ron Kozilcowski; Lloyd Concrete; Bill Lyons; Materials Testing, Inc.; Mike Purinton; Smith Brothers Concrete; Tilcon, CT; Wacker Neuson; Con-Cure Corporation; JGW Concrete.

Reflection & Farewell

This month’s letter from the CFA Executive Director:

Reflection & Farewell

It has been nearly twenty-two years since I took the helm of the Concrete Foundations Association at the suggestion of Larry Clark. We now live in a different world. The country, the industry, and the Association have undergone great change in that period. We have endured several administrations, natural disasters, the greatest recession in most of our lifetimes, and an attack that has changed all of our lives forever. But we have endured.

While concrete hasn’t changed a lot – it still gets hard and it still cracks – technology has improved the properties, process and delivery of concrete. I remember Herbert Construction spent an unfathomable amount on their first Total Station and everyone thought they must have had a few brain cells frozen when they were in Michigan. Layout is now done by one or two men faster and more accurately than thought possible and most companies have at least two or three Total Stations on board. Chemicals have improved the properties. Things like water reducing agents allow faster and more accurate placement of better quality concrete. Pumps or conveyors are now a standard accessory for many foundation companies.

There is now an ‘ACI Residential Concrete Code’ that is referenced by the ‘International Building Code’. An endeavor over 9 years and 14 drafts in the making. Thanks to the input of CFA members such as Buck Bartley, Ron Colvin, Barry Herbert and Brent Anderson, we have a contractor friendly code that specifically addresses many needs and concerns in our industry. The CFA has its own standard which goes well beyond the ACI document in its scope. With the help of Mary Wilson and Lance Jordan, the CFA has a cutting edge ‘fall protection plan’ to address concerns resulting from scrutiny by our friends at OSHA.

The Association has also undergone significant change. We have our own magazine, we have individual and company certification, we have an ever changing and robust web site with depth and breadth in its content…to mention a few items.

The summer convention is regaining momentum after the retraction caused by the recession. While electronics have changed many things, they cannot substitute for face-to-face meetings. The summer meeting presents the opportunity for networking at its finest, as well as a great place to bring the family.

CFA printed publications, which formed the backbone of many member marketing efforts, have gone the way of the fax machine and land line telephone. They still exist but are being rapidly replaced by electronic information and communications. The Internet, World Wide Web, and improvements in computers, software, and printing allow all of us to be our own publishers and to update information on the fly.

One thing hasn’t changed however, and that is our members and the commitment they have to the industry and their Association. But all things must pass. Effective January 1, 2015 a new but familiar face became the executive director of CFA as I ease into retirement. Jim Baty has been with me for nearly 15 of those 22 years so the transition will be seamless. I will be working part time, assisting in the big events, trade shows, ACI, and certification if for no other reason than to extend old friendships and make new ones. Jim has been increasing his role in CFA nearly every year so I know I have left you in good hands. I wish the CFA and Jim the best for the next 22 years and beyond.

Letter from the President: What My Toolbox Looks Like…

This month’s letter from the CFA Board President:

What My Toolbox Looks Like

David Martinson Martinson Construction davem@martinsonconstruction.comIf your company is like mine, the start of the new year, while certainly not a surprise, brings forward a list of what we didn’t get accomplished last year compared to what we did manage to achieve. Fortunately, I’m happy to be able to say that what we accomplished was far more than we perhaps even imagined and it seems the economy in our market is rolling in a positive trend. I certainly hope that is the case to you.

As president of the CFA, I also have an acute understanding for how the Association is doing and the reasons behind the results. No doubt you have seen the countless emails our staff is sending, announcing new company after new company, returning member after returning member. There is a surge in membership growth right now and it is very pleasing to me. That means many companies, new and old, are beginning to see the toolbox that my company has benefitted from for many years.

My toolbox for Martinson Construction looks like a CFA reference library. I can see the benefits of CFA education affecting my management style and directives as well as the confidence from the project managers that I rely on. The projects we are involved in are prepared for success as we relate concrete code information and practical construction guidelines that have grown out of the technical involvement this Association has put forward.

The crews that we send out have the best chance for efficiency and safety combined and we are fully prepared for any relationship with OSHA because of the leadership established by the CFA.

Finally, anything we come up with, whether business management or construction related, can be tested almost instantaneously among the many professional peers I have met and remain in convenient contact with through the many CFA communication vehicles.

If this describes your current toolbox, than I am very pleased as your current president to know that you have found the fruits of what so many before you have produced. I also look forward to what will be produced in the future through the combined information and efforts you will now lend.

However, if this does not describe the look of your toolbox, I want to encourage you right now to make what is perhaps the easiest investment you will ever make in your company…that of joining the one association that is truly yours, mine…ours.