American Concrete Institute Announces New Structural Concrete Specifications

FARMINGTON HILLS, Mich., Aug. 8, 2016 /PRNewswire/ — The American Concrete Institute announces the availability of two important new documents for concrete industry professionals: ACI 301-16 Specifications for Structural Concrete, and the ACI Field Reference Manual.

ACI 301-16 Specifications for Structural Concrete is a reference specification that an architect or engineer can apply to any construction project involving structural concrete by citing it in the project specifications. A mandatory requirements checklist and an optional requirements checklist are provided to assist the architect or engineer in supplementing the provisions of this specification as required or needed by designating or specifying individual project requirements.

The first five sections of the specifications cover general construction requirements for cast-in-place structural concrete and slabs-on-ground. These sections cover materials and proportioning of concrete; reinforcement and prestressing steel; production, placing, finishing, and curing of concrete; formwork performance criteria and construction; treatment of joints; embedded items; repair of surface defects; and finishing of formed and unformed surfaces. Provisions governing testing, evaluation, and acceptance of concrete as well as acceptance of the structures are included. The remaining sections are devoted to architectural concrete, lightweight concrete mass concrete, post-tensioned concrete, shrinkage-compensating concrete, industrial floor slabs, tilt-up construction, precast structural concrete, and precast architectural concrete.

“There are several major updates to the 2016 document from previous version published in 2010, including more contractor-friendly language, removal of default requirements for slump, and provisions on alkali silica reactivity,” states Michelle Wilson, Chair, ACI Committee 301, Specifications for Structural Concrete. “The specifications have been made clearer for the user by removing wording that is confusing or subject to interpretation.”

ACI 301-16 complements the completely reorganized ACI 318-14 Building Code Requirements for Structural Concrete. This enables the designer to use the 301 specifications to complement the design. The specifications are totally inclusive of virtually all forms of structural concrete that are utilized in the building construction industry.

The ACI Field Reference Manual is a compilation of documents including ACI 301-16 Specifications for Structural Concrete and additional ACI documents on measuring, mixing, transporting, and placing concrete; concrete pumping methods; hot- and cold-weather concreting; consolidation; and concrete formwork. ACI 301‑16 requires that contractors keep a copy of the ACI Field Reference Manual in the field office of any project where ACI 301 is specified. The following documents are contained in the ACI Field Reference Manual:

301-16 Specifications for Structural Concrete

117-10(15) Specifications for Tolerances for Concrete Construction and Materials

117.1R-14 Guide for Tolerance Compatibility in Concrete Construction

211.5R-14 Guide for Submittal of Concrete Proportions

224.1R-07 Causes, Evaluation and Repair of Cracks in Concrete Structures

302.1R-15 Guide for Concrete Floor and Slab Construction

302.2R-06 Guide for Concrete Slabs that Receive Moisture-Sensitive Flooring

303R-12 Guide to Cast-in-Place Architectural Concrete Practice

304R-00(09) Guide for Measuring, Mixing, Transporting, and Placing Concrete

304.2R-96(08) Placing Concrete by Pumping Methods

304.4R-95(08) Placing Concrete with Belt Conveyors

305R-10 Guide to Hot Weather Concreting

305.1-14 Specification for Hot Weather Concreting

306R-10 Guide to Cold Weather Concreting

306.1-90(02) Standard Specification for Cold Weather Concreting

308R-16 Guide to External Curing of Concrete

308.1-11 Specification for Curing Concrete

309R-05 Guide for Consolidation of Concrete

347R-14 Guide to Formwork for Concrete

347.3R-13 Guide to Formed Concrete Surfaces

423.7-14 Specification for Unbonded Single-Strand Tendons

ITG-7-09 Specification for Tolerances for Precast Concrete

Learn more about the new ACI 301-16 by viewing this video.

ACI 301-16 is also included in the new 2016 edition of the Concrete Construction Special Inspector reference package. The American Concrete Institute also has ACI 301-16 online learning opportunities:

ACI 301-16 Specifications for Structural Concrete (Part 1)

ACI 301-16 Specifications for Structural Concrete (Part 2)

ACI 301-16 Specifications for Structural Concrete (Part 3)

Learn more and purchase both documents at www.concrete.org or by calling 248-848-3700. Join the conversation by following #ACI301.

For more information, contact:

Julie Webb

Marketing Communications Specialist

p +1.248.848.3148

American Concrete Institute | Always advancing

www.concrete.org

Always advancing – The American Concrete Institute is a leading authority and resource worldwide for the development and distribution of consensus-based standards and technical resources, educational programs and certifications for individuals and organizations involved in concrete design, construction and materials, who share a commitment to pursuing the best use of concrete. ACI’s inclusive, individual member-driven structure and valuable, cost-effective benefits result in an essential organization that invites partnerships and welcomes all concrete professionals who wish to be a part of a respected, connected social group that provides an opportunity for professional growth, networking, and enjoyment.

Dodge Data & Analytics Launches PlanRoom Service for Construction Contractor and Subcontractor Community

Free service provides secure location for users to share and access information from bid phase through project completion

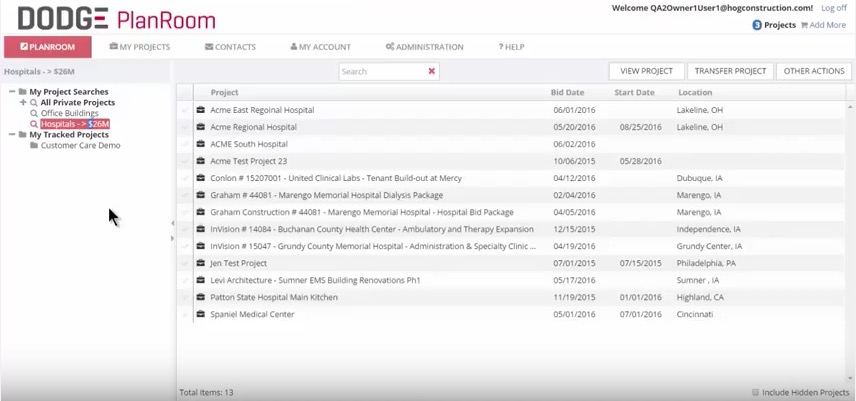

NEW YORK, August 3, 2016 – Dodge Data & Analytics has launched Dodge PlanRoom, an online service for contractors and subcontractors to store, manage, and share plans, specifications, and other construction documentation. Dodge PlanRoom is designed to support construction-specific workflows such as evaluating potential projects by quickly reviewing linked plans, sections and elevations. More information and a free version of the service are available at http://www.construction.com/dodge/planroom.asp.

View a video demonstration of this software at www.youtube.com/watch?v=63llwft8xso

Through optional integration with Dodge Global Network, the largest, most comprehensive source of information on construction projects in North America, contractors can quickly search and view projects to find the ones most suitable for them. Users can also add their own projects or participate in private projects they are invited to by owners and other contractors.

“Dodge data is a crown jewel in the AEC technology landscape and we’re on a mission to unlock the value in our data for all industry participants,” said Mike Petrullo, CEO of Dodge Data & Analytics. “PlanRoom is a great example of this by making Dodge data seamlessly available for contractors and trades to find and win new work, without the need for expensive, complicated packages. We also see tremendous potential for Dodge data to benefit other AEC processes and workflow tools, from both Dodge and other technology providers.”

By helping to make relevant project documentation available in a single, secure repository, PlanRoom allows the whole project team – general contractors, subcontractors and trades, manufacturers, distributors and service providers – to collaborate throughout the entire project lifecycle. Simplified project syncing means that the team can avoid the headaches and delays caused by working with out-of-date information. And version control ensures a document record that allows contractors to track history and pinpoint plan changes when necessary.

“Viewing project information and documents with Dodge PlanRoom is easier and faster than any other product we have used,” said Matthew J. Brennan, Chief Executive Officer, Loveland Excavating and Paving, Inc., in Fairfield, Ohio.

PlanRoom is available in multiple tiers, all of which offer access to unlimited users on a project. The basic level is available free and comes with storage of up to five projects at a time. Subsequent tiers offer increased storage for low monthly fees.

For more information on PlanRoom and to sign up, visit http://www.construction.com/dodge/planroom.asp.

# # #

About Dodge Data & Analytics: Dodge Data & Analytics is a technology-driven construction project data, analytics and insights provider. Dodge provides trusted market intelligence that helps construction professionals grow their business, and is redefining and recreating the business tools and processes on which the industry relies. Dodge is creating an integrated platform that unifies and simplifies the design, bid and build process, bringing data on people, projects and products into a single hub for the entire industry, from building product manufacturers to contractors and specialty trades to architects and engineers. The company’s products include Dodge Global Network, Dodge SpecShare®, Dodge BuildShare®, Dodge MarketShare™, and the ConstructionPoints and Sweets family of products. To learn more, visit www.construction.com.

Board Adopts CFA Newsletter Sponsorship Program

The CFA decided at its board meeting on Friday, October 17, 2003, in Denver, Colorado to proceed with a newsletter sponsorship program. Management has received several requests to purchase additional copies of the popular publication for distribution to customers, builders, building code officials, and within their own companies and this program makes that possible.

The newsletter has expanded and improved from its origins of a four-page, black and white publication to a full color 28-32 page magazine published six times annually. It features news, stories, events, and other information of interest and value to hose in the poured wall industry.

CFA members can purchase additional subscription for $20.00 per year (six issues). The CFA agrees to keep the names on file and will send the subscriptions.

“Build with Strength” to Provide Concrete Information and Resources for Seattle, WA Design / Build and Construction Markets

Seattle, WA – Build with Strength, a coalition of the National Ready Mixed Concrete Association (NRMCA), will be launching new resources, training programs, and educational content in Seattle, Washington as part of increased efforts to inform the design / build and construction communities about the advantages of concrete construction in the low- to mid-rise residential sector, and in general.

The launch of the Seattle programs comes on the heels of a legislative victory in February that saw the Washington State Legislature reject a bill that would have granted tax breaks for the use of a product known as cross laminated timber (CLT). In an oped for The Tacoma News Tribune, Allen Hamblen, president of CalPortland Co., a building materials and construction solutions provider to the Western United States and Canada since 1891, and the former chairman of the Board of Directors of NRMCA, argued that subsidizing CLT’s as a construction material is not only dangerous because “wood rots, molds and, worst of all, it burns,” but because architects will be incentivized to prioritize the price differential over safety. As part of the “Build with Strength” launch, multi-media content will be shared throughout the month that highlight the strength and durability of concrete and concrete products, especially when compared to wood construction.

“Even in the timber industry’s backyard, it’s critically-important for the design / build community to know why building with strength is the only way to assure long lasting, safe and cost effective construction,” said Kevin Lawlor of Build With Strength. “With concrete, the advantages are clear as day: durability and strength cannot be substituted with wood simply because wood is abundant and cheap.”

Last year, Washington State experienced the largest wildfire season in its history, claiming 176 homes and burning more than a million acres. Yet buildings constructed with concrete, like Okanogan County resident John Belles’ home, were left standing after the inferno tore through the countryside. Build with Strength hopes to extend this type of safety and durability into the booming low- to mid-rise residential market.

“As Washington and the entire Pacific Northwest enter wildfire season, the onus is on those with the means to make a difference to ensure Washington State’s buildings are constructed with strong and resilient materials,” continued Lawlor.

Visit www.buildwithstrength.com to learn about concrete construction, its ease of use, creative applications, safety and strength and watch our Build with Strength video.

Schwing America’s Concrete Pumps and Truck Mixers Now Use Valspar Coating Technology

Valspar Duraspar Passes Durability Test; Surpasses Finish and Application Test

MINNEAPOLIS, May 31, 2016 – Schwing America has converted its paint coating system to the new Valspar Duraspar® Industrial Performance (IP) coatings and intermix system from The Valspar Corporation, a global coatings leader. Headquartered in White Bear Lake, Minnesota, Schwing America is the first production facility to use the fully commercialized Valspar Intermix system.

The 400,000 square-foot manufacturing plant builds concrete pumps and truck mixers that are distributed in North America. When Schwing decided to change coatings, the team conducted a rigorous selection process, starting with coating durability tests from five different manufacturers. Mark Moschkau, Schwing’s director of operations, reported that Valspar’s Duraspar coating received the highest performance levels in the test. In addition, Moschkau said, “Valspar’s coating sprayed on easily and provided effective edge coverage, so minimal touchup was required. The coverage, gloss and depth was excellent. Our units look great and have a sheen that mirrors a plastic coating. We’re very, very pleased.”

Jason Bolz, Valspar Global Product Director, described how the Duraspar IP coating has been specifically formulated for the needs of the industrial marketplace. “By combining the aesthetics of automotive paints with the rugged performance of industrial coatings, Duraspar IP is designed to withstand the daily rigors of harsh outdoor operating environments,” said Bolz. “The coating not only looks great, but delivers better edge coverage and corrosion protection. And, for customers looking for maximum flexibility in color mixing, they can literally paint the ‘rainbow’ with our paint system by mixing any standard or custom color onsite in a range of volumes.”

Moschkau described the challenge to find a coating that can stand up to the harshest construction environments. “Our pumps and mixers are exposed to weather, chemicals, dust, dirt and flying debris and a daily high-pressure wash to keep the equipment clean and that really puts a coating to the test,” he said. “Not only does the Duraspar IP system maintain its durability, it’s also a beautiful paint. That was one big reason why we switched to Valspar. Our equipment looks fantastic, and our customers immediately saw the difference when we debuted the new coating at World of Concrete this year.”

Schwing is currently installing a second Valspar Duraspar intermix system at the Concrete Pump Repair (CPR), a Schwing company in North Branch, Minnesota, that repaints, repairs, refurbishes, retrucks and resells concrete pumps.

###

About Valspar: If it matters, we’re on it.®

Valspar is a global leader in the coatings industry providing customers with innovative, high-quality products and value-added services. Our 11,000 employees worldwide deliver advanced coatings solutions with best-in-class appearance, performance, protection and sustainability to customers in more than 100 countries. Valspar offers a broad range of superior coatings products for the consumer market, and highly-engineered solutions for the construction, industrial, packaging and transportation markets. Founded in 1806, Valspar is headquartered in Minneapolis. Valspar’s reported net sales in fiscal 2015 were $4.4 billion and its shares are traded on the New York Stock Exchange (symbol: VAL). For more information, visit www.valspar.com and follow @valspar on Twitter.

About Schwing America

Schwing America is part of the Schwing Group, headquartered in Germany with plants as well as sales and service centers in several countries. Located in St. Paul, Minn., Schwing America manufactures industry leading concrete pumps, truck mixers, reclaimers and genuine parts for distribution in North and Latin America. www.schwing.com

Are You Sure You’re Training the Right Things?

Not long ago a training consultant got a call from a sales manager who said, “We need sales training!” The consultant answered, “Are you sure?”

The caller explained that some of their customer service reps were doing four times the volume of others. It had to be because they were better salespeople … right? So, they needed sales training!

The consultant agreed to help, but insisted on observing the company’s top performers to get a better understanding of what sales techniques they were using.

As it turned out, the top producers weren’t better salespeople at all, but rather had developed a more effective method for processing customer transactions. Once the consultant recognized that, it was easy to document their techniques and build short training interactions around them. The result was an almost instant uptick in sales across their entire customer service rep population.

The message? To get the results you want, you need to understand the reality of your situation. Here are some non-obvious, commonsense steps to help you do that and avoid wasting time and resources.

Step One: Get Real Information from the Right People

A modified version of DACUM (which stands for Developing a Curriculum) can be effectively used in situations like that one. DACUM, which was created by educators to design courses, analyzes what people really do and what they need to learn.

In stark contrast to getting only the leadership team or training department heads in a room, training designers should invite the “boots on the ground.” These are the top performers, the gurus, and the go-to people everyone in the organization knows and relies on. A facilitator leverages a process by which they can extrapolate all that delicious institutional or “tribal” knowledge that exists only in their heads.

Diversity of perspective is key here, so don’t be afraid to have a mix of people. Here’s a sample group:

- The new person who really gets it! – That person on your team who’s been in a role for six months to a year and really seems to get it. He or she provides a fresh perspective.

- The go-to person who has been there forever! – He or she can be described as having forgotten more about the job than most people will ever learn. They provide historical knowledge about how the role has changed over the years.

- An adjacent collaborator role – Don’t be afraid to bring in someone who is not in the role, but “close” to it. This individual can provide an outsider’s perspective and bring knowledge and experience to a different role.

- Key stakeholders – This group is essential because they need the results. They are often your champions who need to understand the process and often support your budget.

Step Two: Create an Occupational Definition – Prime their Minds!

Get everyone in the room focused on the role and get discussions about leadership, work ethic and good communication out of the way. You can use a simple quadrant matrix to document:

- Reporting lines – Who does the role report to up, down and laterally.

- Critical knowledge and skills – What specific skills are essential to doing the job well?

- “Nice to have” abilities and traits – What type of person tends to perform well?

- Learned but wasn’t taught – What were those “a-ha moments” your group had on the job?

Step Three: Define the Body of Knowledge for Peak Performance – The Meat and Potatoes!

A Duty/Task Matrix can be used to define the body of knowledge necessary to perform in the role. You only need some big post-it notes and sharpies. Get the information on the wall so everyone can see it. Put duties down the left, and tasks going across left to right.

Here are the definitions and some examples:

- Duties – This is a something that is top-of-mind for the role. It doesn’t have a beginning or an end. It is ever- present while on the job and usually ends in –ing. Some examples:

- Restaurant Manager. Duty: Maintaining food safety

- Automotive Maintenance Manager. Duty: Selling products and services

- Tasks – These are processes or procedures that have a beginning and end. They usually can have a metric associated with them. These roles fulfill duties by repeatedly completing a series of tasks, usually four or more. A defined task requires an object, verb and qualifier. Some examples:

- Restaurant Manager. Task: Wash hands properly

- Automotive Maintenance Manager. Task: Write a customer-facing estimate

When you identify all the duties and the tasks required to fulfill a role, you’ve documented the entire body of knowledge used by your experts in the room. You’ve also just blown your LT away, because they had “no idea!” your people did all this stuff!

Step Four: Understand the Gaps and Criticality

Your Duty/Task Matrix stands before you and now you need to know where the information is and what tasks have the highest impact on performance. Here are steps to follow:

- Draft a Gap Analysis – Go task by task. Where is it documented how to perform this task? In HR? Marketing? Sales? Ops? Or is it in one of your expert’s head? Has it been passed down over time? If it’s the latter, it’s a gap!

- Consider criticality – Everything in your Duty/Task Matrix is important … but what’s most critical? Use a simple rubric and define the impact to the business, performance, individual or team upon failure. Ask the question: If the worker fails to perform this task, does anyone notice? Does it create some rework—possibly a lot? Will you lose a customer? Will someone get hurt?

Step Five: Build Your Plan

You now have all the information you need to build your plan. You know what the role looks like, contained in your Occupational Definition. You know the body of knowledge that needs to be learned, as described in your Duty/Task Matrix. You know what exists and what doesn’t, laid out in your Gap Analysis. And you know what information is critical to performance, as summarized in your Criticality Analysis.

You can build your Learning Maps for the role, from beginner to expert. You can start to design and develop training around the gaps that really impacts performance. You can map these duties and tasks to competencies and leverage them in cross-team training interactions, and make decisions on the right method for delivery

Now you are armed, much like a marketing department, with an analysis of your customer base and potential for results based on empirical data and not simply feelings. Now you can go to your LT with a plan that justifies a budget and will deliver results. Oh, and you’ve done it all in two days. Good luck!

ABOUT THE AUTHOR

Dan Black is the Chief Learning Strategist at Tortal Training. He specializes in GSD – “getting stuff done” and is recognized in the industry as a “pleasantly disruptive force” that challenges conventional thinking on training and talent development. Contact Dan at dan.black@tortal.net

Are You Ready for the URS?

Businesses big and small have vastly different goals and needs – that’s no revelation. However, nearly every company, no matter how big, where they are, or what they sell, agrees on this point: Simplifying and streamlining business practices helps everyone.

Such is the intent of the Federal Motor Carrier Safety Administration’s (FMCSA) Unified Registration System (URS), which is being rolled out in phases.

Of course, as can be the case with any federal regulation, the fine details can get a little confusing (as can the process of getting into compliance). Here are the essentials for navigating the URS.

What is it?

Up to now, all entities regulated by the FMCSA have made use of various forms and processes scattered across platforms both real-world and virtual. The URS will merge all of those into one single online registration system – what the agency is calling a “smart form.”

The intent is to make registrations a simpler, one-stop-shop process, while at the same time increase efficiency, reduce paperwork, and allow the FMCSA to keep more accurate records and better enforce infractions.

The FMCSA estimates that, over a 10-year period, the system will help the industry reap a total savings of $9 million. However, the agency also expects there to be a learning curve, as 16 percent of new registrations are currently submitted on paper.

Who Does the URS Apply to?

Once implementation is complete, the system will handle all record updates and new registration applications for all the entities that the FMCSA oversees. That includes: interstate carriers, brokers, freight forwarders, intermodal equipment providers, cargo tank manufacturing and repair facilities and companies required to hold hazardous materials safety permits.

Mexican-domiciled long-haul carriers are the only entities exempt from the rule.

Know the Dates – and What you Need to do

The FMCSA published its final rule in the Federal Register on October 21, 2015, and a phased launch of the system began on December 12.

The first phase applied to new entrants: As of December 12, all new applicants must go through the URS online system to acquire a USDOT number and Operating Authority. However, any updates required for those new registrations must be filed through existing channels – not the URS.

The next phase begins September 30. As of that date:

- The FMCSA will no longer accept applications by mail or fax. All businesses subject to the rule must use an FMCSA portal account. That can be set up by going here: http://www.fmcsa.dot.gov/urs.

- MC, FF and MX numbers will no longer be issued. USDOT numbers will become an entity’s sole identifier. Companies that currently don’t have one will be issued one before September 30.

- All new private hazardous materials (HM) and exempt for-hire Carriers must provide evidence of financial responsibility (using form MCS-90).

- All new applicants must file a form BOC-3, designation of a process agent.

- A new fee schedule will take effect.

Confused? Have questions? Need assistance with any of the above?

As always, Foley is here to help. We can create a portal account for you, file your BOC-3, and provide guidance on how to prove financial responsibility. For more information, visit www.foleyservices.com or call us at (800) 253-5506.

About the Author

Christa Krajewski has over eight years experience in DOT regulatory issues and is Foley’s resident compliance expert. In her role at Foley, she works closely with customers to ensure they meet federal drug and alcohol testing requirements. She also provides post-audit support, helping carriers get back in compliance and prepare corrective action plans when needed.

Controlling Your Risks in the Ever-Changing Insurance Marketplace

Over the last few decades, the considerations involved in managing a company’s risks have drastically changed.

Business risks that used to be inherent are much different today and, as a result, mitigation techniques are vastly different than those used in the ‘80s, ‘90s or even the ‘00s. As many business owners know, when it comes to the construction industry, the route to success is never an easy one. That is why it is crucial to understand the emerging risks that have the potential to considerably impact a business’ bottom-line. Factors that contribute to the increased growth of emerging risks include new economic, strategic, financial, operational, sales & marketing, technological, and even more recently, personnel developments.

This two part article, featured in this and the next CFA Concrete Facts magazine, will focus on the particular business risks that CFA members have identified in a recent Heat Map survey orchestrated by CFA 360 risk management program. The survey identified the CFA members’ top three business risks as: market competition, injury to a worker, and hiring. CFA respondents universally believe that these top three risks also have the most significant financial impact on their organizations over the coming years as well as present the most frequently faced risks. An interesting vital key point about the top three risks is that they are absolutely intertwined and the failure to collectively consider them will leave businesses unprotected. Simply stated … good hiring practices lead to workplace safety and quality work product, which help all businesses successfully compete in the market place and keep profits on the balance sheet.

The leadership of the CFA has addressed emerging risks for the association with its formation of the CFA 360 risk management program. Several years ago, the CFA leadership identified that controlling a business’s risk exposure to construction risks stretches far beyond what an insurance policy covers and requires that your risk management partner, your broker, must have evolved into having a deep industry expertise outside the standard scope of placing insurance. That partner must have the ability to proactively identify and evaluate business risks, and develop strategic solutions to protect your balance sheet.

Contractor Market Competition

CFA members identify market competition as their number one risk, and state that it consumes the greatest portion of company time and resources. This is not surprising based on the effects that the long, deep recession has had on the residential construction industry. Nearly eight years later, the residential construction sector is finally coming out on the other side, but still nowhere near the levels it was prior to the recession. Surprisingly enough, experience has taught us that more contractors go out of business during a recovery than during a recession. Margins remain very low as contractors compete to gain-back market share, while funding for construction remains far below pre-recession levels. Lack of adequate planning, poor financial strategies, poor record keeping, and excessive debt, to name just a few—identify the unique aspects of the construction business and brings added risks. Uncertainties of project financing, uneven profit recognition, weather, tedious and absent contract terms, lower labor productivity, labor shortage, tight schedules, and reliance on sub-contractors and suppliers add even more risk. Add them all together and it’s no wonder that consistent profitability and long-term success are such a challenge for contractors.

How do you beat the challenges described above — sell yourself differently than your competition does! Bragging about your risk management program is one of your best hidden tools when marketing your company to owners, builders, and general contractors. A robust and strong risk management program should be used as leverage against your competition. Much like the CFA heat map results, our General Contractors’ and Owners survey showed their number one concern as being able to hire a sub- contractor with a solid risk safety program. It just makes good business sense for them financially since the general contractor’s profitability is directly related to the performance of its sub-contractors. In this instance, partnering with your insurance broker to better publicize your risk management program can be a leading factor in being considered for a project and, often times, the key to a company being awarded the work in a tight bidding situations. There are a lot of different ways this can be accomplished. One way is to set up a marketing campaign that promotes the fact that your company has a positive experience modification.

How to be a smarter bidder? With increased competition, the dynamics of the bidding process has become progressively more difficult for contractors to manage. At the top of the list of business costs included within your bids are those contained in your insurance premiums and hopefully the management of your risk management strategy. It seems only logical that the best way to address all of the aforementioned areas of concern is to establish a bid rate within your job costing model that includes the realistic risk management cost ranges for your average projects. The key elements to always consider and factor into a Total Cost Risk, as well as the bidding rates, include:

- Training/Hiring

- Premiums and Retentions

- Insurance renewal fluctuations especially where projects are long-term

- Safety Program Administration and equipment

- Regulatory costs – OSHA and NCCI

- Return to work programs

- Administrative and internal risk management costs

- New Equipment

Why on earth would I raise my bid rates? The reason is simple; once you are able to measure your total cost of risk, your next step should be to plan to drive down the costs that drive the premium everyone is so eager to talk about. However, if you count the pennies, the dollars will take care of themselves. Likewise, if you count the costs within the Total Cost of Risk, the premium dollars will naturally take care of themselves! Costs that make you a more educated bidder protect your profits on a job while indicating to the general contractor or owner you are serious about your risk management program.

Your competition comes in all shapes and sizes, and the level of sophistication and their internal risk management capabilities can vary widely. You need to be in a position to make refined business decisions that allow you to be more aggressive on jobs that you realize are in your company’s wheel house verses jobs where you are less confident. By adding Total Cost of Risk into your bid rates you will have that flexibility and the ability to focus on the projects that are best suited to your business and appetite for risk.

The CFA 360 Risk Management Strategies to Address Marketing Competition:

- The trick is to develop a method of calculating your Total Cost of Risk to protect your bottom-line while validating those costs for owners,

- Market your company’s best practices to your buyers, and

- Develop a competitive advantage or wiggle room when bidding or negotiating projects.

Hiring

Put aside the heavy equipment, powerful tools, concrete, steel beams and other tangible costs associated with the construction industry. Hiring and retaining talented employees requires companies to focus on the intangibles, such as a potential hire’s individual goals and values. Number two on your list of risks, and for good reason, is the risk of Hiring. Smart hiring plays a key role in managing your risk. CFA companies must strategize about their hiring decisions, continually assessing their workforce and aligning them with future business plans. It sounds obvious, but it’s really about hiring the right people. Shortages in skilled workers are expected to grow. The average age of skilled workers in America today is 55, and if they had the choice, most of the people in that group would retire today. As the baby boomer generation reaches retirement age, and the entry rate of new skilled laborers remains stagnant, the shortage in the skilled labor workforce will continue to grow. In addition, there are emerging risks, such as dealing with the Millennials. Millions of dollars are being invested into figuring out how to hire, train, and retain this new generation of workers. Changes in federal laws that include the Fair Labor Standards Act, which will increase the salary level for exempt employees, the OSHA Respirable Silica Standard, raising cost of medical treatment for injured workers, and the potential for higher interest rates will all impact the new construction housing market.

Being aware of and having a plan to address all of these emerging cost drivers will allow you to create a more positive business plan that reduces risk factors.

What practices have you designed and implemented to manage the risk of hiring? Internally tightening up your job descriptions is one way to create a more focused hiring process that will give you a clear idea of what type of employee is the right fit for your company. There are some economical ways to implement testing and candidate evaluation on the front- end of hiring that can help you make better choices among the applicant pool in your industry. Furthermore, detailed testing such as background checks, personality assessments, and strength/capabilities testing are also excellent ways to gain insight into the background of a potential hire.

Do you know what incentives you offer your employees and candidates as opposed to your competition? Increased competition in the job market means that employers are implementing measures such as continuing health benefits beyond construction season, and offering paid vacations, sick leave and retirement plans, will attract the best talent. Potential employees also are looking for things that will enrich their careers and enhance the quality of their work lives, such as continuing education and excellent safety programs.

The CFA 360 Risk Management Strategies to Address Hiring Risks:

- Sample the CFA membership to examine benefits packages that are offered workers, gain insight on what is working and what is not.

- Leverage the CFA buying power to implement a system that will assist members in hiring practice via pre-hire testing. And,

- Develop a plan to that gives CFA members a competitive advantage in the job market.

Every person matters. As a result, safety matters even more. Establishing a commitment to a strong safety culture that will protect your employees and business partners has enormous value. Likewise, updating your company’s strategic safety plan with innovative solutions and safety training methods as the industry continually develops will aid in carrying your company’s legacy into the future. Stay tuned for the next Concrete Facts article for the continuation of this deep dive into the topic of Injury to a Worker / Work Place Injury.

Despite the always changing construction risk environment, some business owners still buy insurance based only on evaluating their premium dollars and do not evaluate or consider how their insurance broker assists in managing all their business risks. Buyers who have developed along with this transition have adopted their buying considerations on managing risks and gauge their annual insurance costs are impacted by those risks, based on a Total Cost of Risk approach. Managing your business’ Total Cost of Risk measures all financial considerations that include the insurance choices, but also allows the buyer the ability to measure the financial aspects of all known risks.

Plan of Action for Implementing OSHA’s Final Rule on Crystalline Silica Exposure

On March 25, 2016, the Occupational Safety and Health Administration, OSHA, issued its final rule on exposure to crystalline silica in the workplace.

The final rule is decades in the making, and has seen many stumbling blocks along the way, but Dr. David Michaels, Assistant Secretary of OSHA, saw the new standards as one of OSHA’s biggest priorities under his leadership and was determined to see them released.

The new standards are expected to have a significant impact on both the general and construction industries and cost employers nearly one billion dollars to implement, although many groups conclude that the costs are significantly greater. Since its release, several legal challenges have been filed against the new standard. It is too early to say what impact those challenges will have on the final rule.

Currently, construction employers must comply with all requirements of the standard by June 23, 2017, except requirements for laboratory evaluation of exposure samples, which are given until June 23, 2018.bBecause of the short amount of time to implement the rule, which is one year less than general industry was given to come into compliance, construction employers should review the standard’s requirements and develop a plan of action for meeting this deadline.

Silica Standard Requirement

OSHA’s new standards significantly reduce the Permissible Exposure Limit (“PEL”) for crystalline silica and require construction employers to implement engineering and work practice controls and follow several “ancillary” provisions, such as medical surveillance, a written exposure control plan and housekeeping practices.

- More specifically, the new standards set a PEL of 50 μg/m3 (from the previous PEL of approximately 250 μg/ m3) measured as an eight-hour time-weighted average (“TWA”). If workers are exposed to crystalline silica above the new PEL, all construction employers must implement engineering controls by using local exhaust ventilation (e.g., vacuums) or a water delivery system. All construction employers also must: Establish and implement a written exposure control plan that identifies the tasks that can result in silica exposure, the engineering controls, work practices, and respiratory protection that will be used to protect workers, and the procedures to restrict access to work areas where high exposures may occur.

- Designate a competent person to implement the written exposure control plan by making frequent and regular inspections of job sites, materials, and equipment.

- Restrict dry sweeping or dry brushing where such activity could contribute to employee exposure to respirable crystalline silica unless wet sweeping, HEPA-filtered vacuuming or other methods that minimize the likelihood of exposure are not feasible.

- Offer medical exams at no charge to the worker—including chest X-rays and lung function tests— initially (if not received within the last three years by another employer) and every three years for workers who are required by the standard to wear a respirator for 30 or more days per year.

OSHA also has implemented a unique approach to compliance with the revised PEL and exposure monitoring requirements for construction employers. Construction industry employers are exempt from meeting the PEL and performing exposure monitoring to crystalline silica if they comply with specific engineering controls, work practices and respirator use discussed in the new standards, as outlined in Table 1. Table 1 identifies 18 construction tasks that could generate exposures to respirable crystalline silica and for each task, specifies engineering controls, work practices, and respiratory protection to protect workers.

The identified “Table 1” tasks include:

- Stationary masonry saws

- Handheld power saws (any blade diameter)

- Handheld power saws for cutting fiber-cement board (with blade diameter of 8 inches or less)

- Walk-behind saws

- Drivable saws

- Rig-mounted core saws or drills

- Handheld and stand-mounted drills (including impact and rotary hammer drills)

- Dowel drilling rigs for concrete

- Vehicle-mounted drilling rigs for rock and concrete

- Jackhammers and handheld powered chipping tools

- Handheld grinders for mortar removal (i.e., tuckpointing)

- Handheld grinders for uses other than mortar removal

- Walk-behind milling machines and floor grinders

- Small drivable milling machines (less than half-lane)

- Large drivable milling machines (half-lane and larger)

- Crushing machines

- Heavy equipment and utility vehicles used to abrade or fracture silica-containing materials (e.g., hoe-ramming, rock ripping) or used during demolition activities involving silica-containing materials

- Heavy equipment and utility vehicles used for tasks such as grading and excavating but not including: demolishing, abrading, or fracturing silica- containing materials

For those employers who cannot or choose not to follow Table 1, they will be required to ensure that no employee is exposed to respirable crystalline silica in excess of 50 μg/m3, calculated as an 8-hour TWA. Construction employers will be required to use engineering and work practice controls to reduce and maintain employee exposure to or below the PEL and perform exposure monitoring of employees who are or may reasonably be expected to be exposed to respirable crystalline silica at or above 25μg/m3.

Training is another key requirement under the new standard. Construction employers are required to communicate and train employees on the hazards associated with crystalline silica under the Hazard Communication Standard and ensure that each employee has access to labels on containers of crystalline silica and safety data sheets. Training must address the hazards of cancer, lung effects, immune system effects, and kidney effects from exposure to respirable silica. Employers also must ensure that employees can demonstrate knowledge and understanding of:

- The health hazards associated with exposure to respirable crystalline silica;

- The specific tasks in the workplace that could result in exposure to respirable crystalline silica;

- The specific measures the employer has implemented to protect employees from exposure to respirable crystalline silica, including engineering controls, work practices, and respirators to be used;

- The contents of the new standard; • The identity of the competent person; and

- The purpose and a description of the medical surveillance program.

Plan of Action

Because of the significant costs and rigorous requirements of the new standard, employers should review their silica program now and develop a timeline for meeting the compliance obligations under the new standard. A proposed plan of action should consider the following:

- Review any existing equipment to determine whether it can be retrofitted with local exhaust ventilation (e.g., vacuums), a water delivery system or some other control, or whether new equipment will need to be found and purchased. Take an accounting of both.

- Research vendors and the costs to retrofit or purchase new equipment. Determine the overall costs and unit price for making upgrades or purchasing new equipment and develop a purchasing plan that spreads costs over the next 13 months. Coordinate with your occupational health medical partner (or find one if you do not already have a partner in place) to assist you in meeting the medical examination requirements. They can help you understand the medical requirements and come up with a program to ensure that the requirements are completed in the most cost effective manner possible.

- Develop records or procedures to ensure that you are able to keep track of which employees have received a medical examination and when medical examinations are due.

- Review Table 1 tasks and determine if your operations can fit neatly within the enumerated tasks, and if adoption of Table 1 is feasible, paying close attention to the work practice controls discussed.

- If unable to adopt Table 1, consider the exposure level of your employees and whether their exposure to respirable crystalline silica is reasonably expected to be at or above the action level of 25μg/m3 (the answer will usually be yes in light of how low the action level is).

- Locate a vendor who can perform exposure monitoring, or consider whether you should hire an industrial hygienist or other individual with training on correctly performing exposure monitoring as part of your full-time staff. If frequent monitoring is necessary due to the various types of jobs or variable nature of the work, hiring someone trained on this task may be a more cost effective approach.

- Draft your written exposure control plan and any necessary forms that will be used for each project after you have determined the engineering controls, work practice controls and respirators that you need to implement.

- Designate your competent person(s) to implement the written exposure control plan and consider whether they need additional training on the hazards of silica, identifying silica exposure and inspecting for compliance.

- Revise your safety manual to reflect the new requirements.

- Update your training materials and ensure that you have covered the necessary components of the rule and have methods in place for documenting the knowledge and understanding of employees.

- Consult an attorney or a safety health professional if you have questions or need assistance!

ABOUT THE AUTHOR

Nickole Winnett is a Principal in the Washington, D.C. Region office of Jackson Lewis P.C. and is a member of the Employment Litigation practice group and the Workplace Safety and Health practice group. She routinely advises clients regarding all aspects of the employment relationship, including safety and health counseling in the construction and manufacturing industry. She may be reached by email at nickole.winnett@jacksonlewis.com.

CFA Member Benefit: The Employee Manual

One of the most important parts of any business is establishing the boundaries between management and employees that protect both in times of discipline. The policy manual is the tool used to provide prospective employees with the picture of expectations by the employer, as well as maintaining an ongoing and effectively positive relationship.

Employee manuals are often difficult to write and they can become choked with good intent that lingers into weak and challenging implementations. Although it is important for employers to maintain succinct policies, they do need to be as complete and thorough as possible in order to establish both boundary and consequence.

The Concrete Foundations Association has partnered with employer law expert and attorney, David Whitlock, to create an opportunity for its members to improve their structured employee manuals (or establish one where they might be non-existent). This effort is designed to continue the professional improvement of each and every organization in membership with the Association and help the collective structure evolve a more comprehensive approach to managing concrete contracting companies.

In order to facilitate this evolution, Mr. Whitlock and the CFA are prepared to release to each Association member, a basic employee manual.

This manual can be the sound foundation for a company to jump to a higher level of preparation and performance with their staff or it can be an excellent tool to streamline or upgrade their existing workforce policies.

In order to get a picture of how this manual can address important areas of your business and get a feel for the type of guidance to be found in this manual, a sample policy appears at below.

Some companies will find that with this basic manual they are ready to update and improve their skilled approach to managing their workforce expectations. However, others will find it necessary to work directly with a specialist to fine-tune their policies and perhaps take a bit more of a custom approach. For these companies, CFA has also created an opportunity with David Whitlock for a one-to-one relationship at an exceptional rate as a CFA member. Where companies can dump thousands of dollars into a custom employee manual development process, CFA members will have access to one of the industry’s foremost experts at an attractive rate.

For more information on this employee manual kit, contact CFA Headquarters at 866-232-9255, or send email to Executive Director, James Baty at jbaty@cfawalls.org.

SAMPLE POLICY: SOCIAL MEDIA POLICY

We understand that social media can be a fun and rewarding way to share your life and opinions with family, friends and co-workers around the world. You should understand, however, that use of social media also presents certain risks and carries with it certain responsibilities. To assist you in making responsible decisions about your use of social media as it relates to your employment, we have established these guidelines for appropriate use of social media.

This policy applies to all employees who work for [Employer], or any parent, subsidiary, or affiliated entities in the United States.

Guidelines

As part of the rapidly expanding world of electronic communication, social media can mean many things, including any means of posting information or content or communicating on the Internet. This might involve your own or someone else’s web log or blog, online journal or diary, personal or group web site, social networking or affinity web site, web bulletin board or chat room, as well as other new or evolving means of communication. Please note that social media, as defined here, is not limited to means of communication associated or affiliated with [Employer], although these guidelines should also be taken in to consideration as part of your use of any of [Employer]’s means of communication. The more common social media outlets today include Twitter, Facebook, MySpace, LinkedIn, YouTube, etc.

The same principles and guidelines found in [Employer]’s policies and core beliefs should also guide your use of social media. Ultimately, you are solely responsible for what you post or communicate online. Because there are risks and rewards involved, we ask that you think carefully before creating or posting online content. Bear in mind that if your conduct or content adversely affects your job performance or that of other employees, or if what you do or say adversely affects our customers, suppliers, agents, shareholders, or others affiliated with our business or [Employer]’s legitimate business interests, there may be disciplinary consequences.

Please Abide By Our Other Policies

Your use of Social Media may involve other policies of [Employer]. For example, please follow the policies affecting use of computers, telephones, and other means of electronic communication, as well as our Ethics and Harassment Prevention policies. If you post inappropriate content, e.g., discriminatory remarks, harassing statements or images, threats, bullying, or similar inappropriate or unlawful conduct, you may be in violation of other policies and that could result in discipline. Note that this is the case if you post this kind of inappropriate content from home or work.

Please Treat Others With Respect and Dignity

We think it just makes sense for all employees to treat others with respect and dignity, but it is especially important to be fair and courteous to fellow employees, customers, suppliers, guests and visitors, and others connected to our business and our legitimate business interests. To the extent that you have concerns, criticisms, or complaints, we encourage you to raise them openly and honestly by speaking directly to a co-worker, supervisor, Human Resources, or management rather than by posting something online. If you decide to post complaints or criticism online — which is always your right if you choose – please avoid using statements, photographs, video, audio, or other content that reasonably could be viewed as malicious, obscene, threatening, intimidating, or disparaging of customers, co- workers, or others connected to our business interests. Please refrain from posting content that is harassing or bullying. For example, we think that you would agree that such conduct would include content posted intentionally to harm someone else’s reputation or content that might contribute to a hostile work environment on the basis of race, sex, disability, religion, or other protected status.

Always Strive To Be Honest and Accurate

We believe that it is inappropriate to post information or rumors that you know to be false or untrue, especially if they relate to co-workers, customers, and others affiliated with our business interests or our competitors. If you later discover that something you thought was true turns out not to be, we think the best course is to correct it as quickly as possible. This might require you to post a retraction or correction. We believe that doing so is the “right” thing to do rather than leaving false or untrue posts on the internet. Remember that nearly everything posted on the internet is archived somewhere, so even what you delete may later be searched and found.

Here are some specific examples of things you should consider.

- Maintain the confidentiality of [Employer] trade secrets and private or confidential information. Trade secrets may include information regarding our systems, processes, products, pricing formulae, know-how, or technology. For further guidance about what we are trying to protect, please consult our [Confidentiality or Trade Secrets] policy.

- It is often a violation of financial disclosure laws to post or communicate a “tip” or inside information that might influence others to buy or sell shares of stock or other securities.

- If you create a link between your blog, website, or other social media outlet to [Employer]’s website, blog, or social media outlet, you must indicate that you are an employee of [Employer].

- Please do not represent yourself as someone speaking for, or on behalf of, [Employer]. If you post content about [Employer], please remember to state clearly that you are an employee of [Employer] and that your views and/or opinions do not represent those of [Employer], co-workers, customers, or others affiliated with our business interests. If you post a blog or content related to the work you do or the business interests of [Employer], please be certain to make it clear that you are not speaking on behalf of [employer] or its business interests. An easy way to do this is to post a simple disclaimer that says: “The postings here are my own and do not necessarily reflect the view/ opinions of [Employer].”

- Please do not use social media while on work time or using [Employer] equipment, unless doing so is work-related and authorized by management. Of course, you are free to use social media on your own equipment during your time off or breaks.

- Please do not use [Employer]’s email address to register on social media networks, blogs, or other outlets that you use for your personal use or activity.

- Please do not speak to any media or outside contact on behalf of [Employer] unless you are authorized to do so. If you are not so authorized, please direct any inquiries to management.Please note that [Employer] prohibits retaliation against any person who reports a possible violation of our policies. Any employee who threatens, takes adverse action against, or otherwise retaliates against another person who has reported a possible violation of our policies or participated/ cooperated in an investigation of same will be subject to disciplinary action.*****

If you have any questions about [Employer] policies or these Guidelines, please contact your supervisor, Human Resources, or management.ABOUT THE AUTHOR

Lindsey Bloomquist, manager of communications and networking for the Concrete Foundations Association (CFA), works to communicate the available tools and benefits of a CFA membership to the industry, and provide networking opportunities that build professional relationships between contractors and industry leading suppliers and manufacturers. Bloomquist also works closely with industry suppliers and manufacturers to increase exposure within the CFA through advertising, sponsorships, exhibits and networking. Reach Lindsey at lbloomquist@cfawalls.org.

“The professional relationships that are established are vital to the success of this association and its member companies. Not only do these interactions foster healthy competition that fuels innovation, but they create lasting partnerships that are beneficial to both the contractors and suppliers.”