Congratulations…O’Risky Excavating Turns 25!

O’Risky Excavating has been a member of the Concrete Foundations Association since 2014. President and owner, Jeff O’Risky, now serves as a member (2018) of the Board of Directors and has been an active participant in networking within the Association since joining.

“Jeff has been one of those guys you just immediately feel energy from,” states James Baty, Executive Director for the Association. “He met us for the first time at World of Concrete and was looking for a colleague network he could learn from and contribute. Since then, he has been a strong participant in many of the more regular and convenient methods of networking through the Hotline and our in-person events. He has also been quick to jump into the convenience offered by the new digital in-person platform being used for Association events during this season of pandemic.”

One of the ways to get to know a company is through the eyes of the employees. “I’ve known Jeff personally for over 30+ years and worked for him only 3 ½ years but Jeff’s true passion for his company is very sincere,” states Leeanna Wassmer, office manager. “His drive and determination are contagious; it makes each of our team want to be a part of this success.”

The company continues to grow in many ways while focusing on the things they do extremely well and empowering others to come along and take control of the successful parts of their business that may not fit precisely within the vision Jeff has for the company. In today’s market and recent economic conditions contractors in and around the CFA realize that 25 years is a pretty big accomplishment.

No planned celebration is set at the current time, but as the pandemic context begins to shift more towards latitude, later in the summer is their goal for welcoming customers and others connected in business.

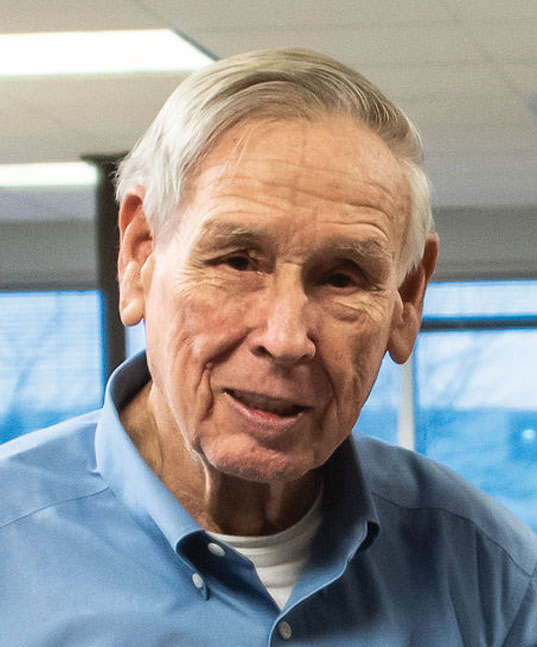

Joe Carr, Custom Concrete (1934-2021)

The Concrete Foundations Association owes considerable gratitude to Joe Carr of Custom Concrete (member since 1986) a true pioneer in this industry. His passing leaves both a hole in the spirit that established this Association and a legacy of leadership to continue building the future. “Joe had a very influential part in allowing me to begin managing the interests for the Association,” states Ed Sauter, former Executive Director. “Bob Sawyer passed the torch to Roger Nielsen and then Roger decided to enter retirement, it was Joe and Larry Clark (Concrete Facts 27-2) whom I recall having the most to say about who would next manage the Association.”

In a press release, Custom Concrete released the following:

Custom Concrete (Westfield, Indiana) celebrates the life of its founder, Joe Carr, who went to be with the Lord on Saturday, January 23. Not only did Joe’s leadership impact the thousands of employees, customers, and partners over the years, but he led far beyond the walls of Custom Concrete through being a leader to his family, in the community, and his church.

In 1969, Joe moved to Westfield, Indiana, where he and his wife (Betty Carr) began their home framing business, Custom Framing. Over the years, Custom Framing became Custom Concrete and has operated as a family business for over 51 years. What started as a man and his truck grew toan enterprise of over 400 employees.

“We at Custom Concrete are saddened for the Carr family and the passing of Joe. We know his legacy will live far beyond his time on earth. Joe built a company on a solid foundation and commitment to values that have been instrumental in creating the company standards. Our company will forever have his imprint,” Jason Ells, Senior Vice President.

Followed by his memorial service, the procession drove through the Custom Concrete facility as a memorial tribute. The company ‘shut-down’ for a few hours to allow all employees to come remember Joe Carr and show the family support as the motorcade arrived. The team honors Joe and how he built a company rooted in a foundation for quality: character, service, relationships, and values.

“I recall fondly just how much Joe Carr helped my company in the early days,” stated Barry Herbert, chairman of Herbert Construction Company of Marietta, Georgia (member since 1992). “He was one of the first we met who was always opent to talk with anybody, share experiences about anything and took a real interest in our company.”

“One of my first recollections of Joe Carr was his coining of the phrase, ‘the ready to wear basement’, a basement we might today describe as turnkey,” stated Ron Ward, CEO of Western Forms (member since 1985). “This basement concept had it all, fully waterproofed and ready for the builder to move in and build the house. Not many guys were doing this at the time and it really set a standard.”

A private family service was held on January 26 in Lebanon, Indiana. The family extends Joe’s wishes for any memorials to be directed to the Samaritan’s Purse:

Why Wait to Form Walls on Cold-Weather Footings?

by JAMES R. BATY II

As most contractors realize, it is quite normal for walls to still be formed on footings the next day (or two) during the colder months of December to March. While concrete does gain strength at a slower rate during this time of the year, the footing concrete placed with just 24 hours of strength gain can be shown as still more than substantial enough to handle the forming operation that takes place next. On Day 2, and then by the end of Day 3, forming and concrete placement does not bring a significant load over the area of contact (Baty 2016)1.

The Concrete Foundations Association (CFA) Cold Weather Research Report documents the work conducted from 2002-04 to establish significant evidence of the ability for concrete temperature to maintain maturity despite sub-freezing ambient air temperatures.

Forty-four different mixes and more than 800 cylinders along with more than 100 core samples from multiple full-scale walls demonstrate that maturity occurs more aggressively than ambient temperature predicts.

In figure 1, the strength gained for forty of the research mix designs based on a 30 deg F ambient air temperature condition is shown ranked based on the green segment representing 500 psi. ACI 3322 requires concrete to be kept above a frozen state until this strength is achieved. It is believed that this early strength level is both sufficient for the concrete to be self-supporting as well as the surfaces strong enough to resist the damage from any expansion due to ice lenses in the interstitial spaces. In just two days, most of these mix designs were well over 1,000 psi and some as great as over 2,000 psi with near design strength or more by the third day.

Keep in mind that the load of an 8-ft wall of concrete is 150 lb/cu ft x 8 ft x 8in./12in. = 800 lb/lin. ft. over the 8-in. thickness. Divide this by an area of 8 in. x 12 in. and you only have a load of 8.33 lb. per sq.in. on the footing. At the very lowest of 1-day strengths for a plain, 2,500 psi mix, you have a capacity 46 times that.

Figure 2 shows the rapid increase of strength ensured by hydration despite a below-freezing curing temperature. By the end of a third day, with this basic plain mix, you have over 2,000 psi. This approaches the required strength for the foundation wall itself to withstand the design backfill pressures when supported or connected properly.

Figure 3 demonstrates the principle of why concrete temperature is the true predictor of strength gain and how cold weather is overcome by it. Here a graph of the ambient temperature profile for a three-day stretch (dark blue) is compared to the measured temperature of the concrete at two key locations, top of wall and center of wall. While a footing is protected even further from the effects of heat loss by radiation, the top of wall condition can be a conservative application as shown here. Once a wall is cast on the footing, the footing curing condition is much closer to the center of wall condition. This is due to the placement of fresh concrete at a warmer delivery temperature to support further hydration and therefore maturity.

While colder air temperatures slow the maturity of concrete and prolonged freezing air temperatures can temporarily halt it, concrete footings will reach sufficient strength for the entire construction process making the forming process elementary provided proper mix designs are selected and manageable precautions employed. For more, visit www.cfaconcretepros.org/toolbox.

References:

“Why Wait to Form Walls on Footings?”, August 16, 2016 by Concrete Contractor magazine | www.forconstructionpros.com

Residential Code Requirements for Structural Concrete (ACI 332-20) and Commentary published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org

Getting Paid

Among the many advancements this Association has made for its members over the last decade, the growing affinity programs, those services and contract opportunities that bring you significant discounts or performance advantages, are among our greatest source of pride. One such program is that from C2C Resources, a global commercial collections agency. Established at the start of 2018, the relationship with C2C Resources has been offering CFA members a great partnership to maintain effective bill collections and protect against write-off losses. Today, that relationship has begun to pay dividends as members are beginning to find traction. – James Baty, CFA Executive Director

How we helped over 35,000 clients collect over 380 million dollars in bad debt

Sven Nelson

CMO – The Guy That Gets You Paid!

For as long as businesses extended credit to other businesses there have been those that couldn’t or wouldn’t live up to their financial obligations. By the same token, for as long as businesses have used credit to grow by taking on risky clients there has been bad debt and a need to collect it. Having over 15 years of experience in the collections industry, I know how stressful and debilitating uncollected debt can be on a business and those managing it. The reality is that a lot of unpaid accounts are simply the result of a business struggling.

The good news – there are multiple paths that a business can decide to take if they have accounts that still need settling.

A lot of companies will first opt to try and collect these unpaid accounts in house. Many of them have full fledge collections teams of their own but most struggle with the time and resources to do the job as effectively as we can in many cases. Regardless there is only so much you can do in house. You can only write so many letters, make so many phone calls and have so many conversations before you are quickly duplicating your own efforts expecting different results. I believe that is the definition of insanity. You would not believe how many accounts get sent over to me that have had multiple “Final Demand letters “sent on the same account. As if getting one more letter with “past due “stamped on it is going to make a difference with someone that has already thumbed their nose at you many times over. While in-house debt collection is important, the true strengths of in-house work lie more on the proactivity side then the reactivity side. Focusing your in-house efforts on bad accounts means your spending less time analyzing your other clients, and you could miss the signs of another client being a bad risk. Ultimately, I usually see this type of work exacerbating a client’s problems, rather than solving them.

Another solution that I get asked about often by clients is whether hiring a lawyer to help collect unpaid accounts is as effective as an agency such as ours. The answer, like many nuanced things in life, is that it depends.

The truth is that our Justice system is not set up to collect money, it is set up to dispense justice, many people get this confused. They think that once they get a judgement that they will quickly be rewarded with a pile of cash or a check coming from their debtor. Unfortunately, this could not be further from the truth. Once you’ve got the judgement, you still must find assets and attach them which is another feat in it of itself. Because of this we only resort to taking a debtor to court in less than 2% of our cases. Legal headaches work both ways and, in some cases, you can be opening yourself up to a frivolous counter suit that could cost you money to defend it. Once a suit is filed the plaintiff can file a counter claim for free, regardless of it’s merit. Keep that in mind when thinking about going to court. You may end up spending a lot of unnecessary time and money tying your account up in the (putting it nicely here) less-than-efficient legal system, perhaps even more than the account is worth, by the time you factor in all that is lost.

I understand that for many, going through the collections process can be just as confusing as going to court. That is why we have assembled a team of experienced people to guide you through the process, equipped with the proven tools, resources, and strategies that have led to us collecting well over a quarter of a billion dollars in bad debt. People that care about your business and the dollars that are at stake.

First, we realize that most accounts are not the white whale – not some giant multi-million-dollar unpaid debt that needs collecting. Many of the accounts that we collect are smaller balance accounts that range in size from $200.00 to $10,000.00 and everywhere in between. That is not to say that we aren’t equipped to handle large accounts, but that we work for everyone. We have hundreds if not thousands of high five, six-figure and seven-figure accounts that we have collected over the years, with many more medium and small accounts on top. We created a tiered system of collectors separated by the size of the account. We have collectors working on small, medium, large, and super large accounts. This ensures that each and every one of our accounts gets worked evenly, no matter how large or small.

Second, we use a drop-down system to ensure that every account gets worked by 2 sometimes even 3 in house collectors on our staff to ensure that nothing was missed by the previous collectors. Then it goes to a finals collector that makes one last attempt. This ensures that we have multiple sets of eyes on our accounts in a 4-to-6-month timeframe and that we are making every effort to collect for our clients before taking any further action. We use the latest and most advanced skip tracing resources – the same software used by law enforcement agencies – to help us track down alternate forms of communication that our clients may not have access to or in some cases may not have provided.

Third, we created our own custom software to track and communicate proficiently with our sales and collections team in house making us a well-oiled machine. In addition, our cloud-based software doubles as an inhouse collections tool for our clients (Profit Maximizer) to use for free that provides reporting systems, scripts and rebuttals for collections, in addition to professionally written collections letters that can all be sent out via fax, email or snail mail. All of this was created to help our clients reduce the need for a third party and mitigate bad debt. This system also allows our clients access to their invoices and remittance statement too.

Most importantly: our people. Our people are passionate about their careers and care about the results, not only for their own monetary benefit, but for the greater good of our clients and the companies we serve. We have a diverse team some with industry specific expertise and knowledge and know-how to satisfy specific clients’ needs. Our average collector has over 30 years of experience in this field, and we make sure that we are constantly bringing in new faces to learn under our experts.

On top of all of that, we strive to create lasting beneficial relationships with our clients. Nothing makes me prouder of the work we’ve done than when I get to call a client and tell them that I just collected in full their eight- or nine-month-old receivable that they just placed with me that morning and that I’ve already got the money in our account. But I also enjoy just as much a call from a client, I’ve had for ten or more years, calling simply to ask me how my children are doing, or what my plans are for the weekend; and I do the same all the time. These are the kind of relationships that foster success, and these are the kind of relationships we forge.

Five Areas of Focus

Doug Herbert

Herbert Construction Company

doug@herbertconstruction.com

The Board of Directors of the Concrete Foundations Association (CFA) got together late last year to determine the direction of the association for the next several years.

The strategic planning meeting spanned three days and covered issues regarding the foundation industry. Our goal for the meeting was to determine how to improve our members’ businesses, provide more value to our members, and grow our association.

We determined that we will focus on five areas:

- Workforce / Talent Development

- Peer Networking / Community

- Membership

- Education

- Advocacy

We have assembled teams of CFA members for each of these five areas of focus. Each team, or task force, will meet virtually over a set period of time and discuss ways we can help our members in that specific area.

The end result is that each task force will have created deliverables that will help our members improve their businesses.

And here’s how you can benefit from this…

We are still accepting participants to join those groups, and we’d like to see you in one. You can join the discussion and help the task force achieve its goals. You will be working with other CFA members to discuss the issues and find the best solutions for moving forward.

But the real benefit that you’ll get out of joining a task force is in talking with other concrete contractors.

Having served on these types of groups in the past, I know one thing is certain:

If you join one, you’ll get more out of it than what you put into it. The ideas you receive and the friendships you make will pay off in many ways.

Four ways you’ll benefit from your involvement:

- You’ll hear what other contractors are doing in their businesses, and get ideas for your own.

- You’ll develop friendships with other contractors that you can call to chat about business issues.

- You’ll learn ways to improve your company while helping others improve theirs.

- You’ll help the CFA create better services for our members and grow the association.

If this is something you want to be a part of, then please email Jim Baty at JBaty@cfaconcretepros.org.

This is a great opportunity to get involved in the CFA and work alongside a terrific group of contractors.

Amazing Leaders…Amazing Minds!

jbaty@cfaconcretepros.org

This past October, the Board of Directors completed a three-day Strategic Planning event. The first such effort since 2012, our collective energies were still focused on the same general sense of goals and strategies, though constantly adapting to fit the needs of the membership and the industry. In nearly a decade that plan had been pushed and pulled, rolled over and marked up so many times that even as close as I am to it, I couldn’t clearly interpret the tea leaves. It was time

In 2012, the Board gathered in a large conference room. Large Post-It notepads were placed around the room and the mud slinging began. I still have those paper images and it seems the wholeness of the strategy was to define and refine who the CFA could be for the future. Considering this Association was established in 1974 by contractors, for contractors, it isn’t hard to imagine the need to stay true to that mission. Today, even more so than just a short decade ago, the networking landscape is vastly different. Information seemingly at your fingertips…Google has proven that you can get a purported answer to any question from any position. Essentially, today’s knowledge base is about bending information to your will… support what you want to be supported.

This past October, I watched a refreshing group of industry leaders, taking valuable time from their businesses, investing in a new vision. There was no discussion of “new identify,” the Concrete Foundations Association doesn’t need that. Five pillars, platforms, areas of interest…these came from the hard work of discussing the past and present and evaluating the opportunities of the future. The Strategic Plan established a core vision for the Association to center energy on strengthening Education, Networking and Advocacy while building new strategies to leverage Membership and Workforce Development. These five aspects of what the Association needs to be for the members become your core values. The Board then installed task forces for each and invited the membership at large to participate.

January rolled in after the holiday season and without World of Concrete to plan around, an intensive four weeks of development work took place by incredibly talented and spirited members. Whether on the Board or serving as a member-volunteer, they took task development to a new level. Eighteen goals for the Association are now prepared for the Board to wrestle with in their February meeting. This represents the structure of the here and now as well as the short to long-term development planned to continue building on the legacy that every Board before had maintained.

I extend my personal thanks with sincere gratitude for the amount of effort put forward that continues to make this association a special place. A place where dedicated and passionate businesses can come together, be supported, contribute and strive for the strongest of futures for our industry, its workforce and their families. The introductions to your new Board members found beginning on page 18 evidence much of this energy and the excitement we should all have for what is to come.

Bartley Corp in Middle Tennessee is Open for Business

Silver Spring, MD (February 3, 2021)

Bartley Corp in Middle Tennessee is Open for Business

The Bartley Corporation announces the opening of a new location that will provide concrete construction based in Springfield Tennessee. Aiming to meet the increasing demand for qualified contractors in Nashville’s booming housing market, the company has established a new team under the leadership of Tom Bartley Jr. and Nery Zabaleta. A local of the Nashville area for 20 years, Tom Bartley Jr. is excited to lead a new team built from 51 years of experience and systems in which his uncle Buck and father Tom built.

“This growth to a new market has been a joy because we have been able to improve our systems and training for our teams in Maryland, while being able to make sure our content applies to Tennessee; or really anywhere,” states Andy Bartley, Vice President. “The unique draw to the Nashville area is a winning combination of having a trusted and established leader in my brother Tom and the booming construction that is taking place in Middle Tennessee. We continue to lean on relationships made from the CFA which has helped make this possible”

The Bartley Corp has been a leader in Concrete Construction since 1970 and continues to be a family owned and operated business. Bartley Corp is based in Silver Spring, Maryland and employs over 160. Bartley Corporation’s construction services include Residential Concrete Foundations, Excavation, Waterproofing, and Commercial Concrete Construction.

Mission Statement: Bartley Corp is a partnership of families with a relentless mission to optimize the foundation construction process; strengthening the world around us. Through safe and rewarding careers, our team members passionately craft and mold liquid rock; the miracle of concrete!

For more information, visit https://bartleycorp.com/about/contact-bartley/middle-tennessee-concrete-foundation-construction/

Media Contact: Andy Bartley

Bartley Corporation

P.O. Box 1299

Ashton, MD 20861

Phone 301-384-2700

info@bartleycorp.com

www.bartleycorp.com

Taking Control of Your Post-Injury Healthcare

by Levi Schrock, Custom Concrete

Though COVID-19 has slowed customer traffic for many companies across America, most construction businesses and medical facilities are as busy as ever. For these construction companies, employees will always face some level of physical risk when on the job — and being pushed to extra fast-paced production usually results in a higher volume of workplace injuries. Simultaneously, hospitals and emergency medical facilities are dealing with full schedules and long wait times while trying to adapt to the COVID-19 restrictions that various states and cities are changing on an almost-monthly basis. This ruthless busyness in two large, symbiotic industries will likely end up causing contractors increased indirect costs for their injured employees’ medical care.

Even pre-COVID-19 there were many reasons for employers to take as much control as possible when it comes to claim management and medical care for injured workers. While we all want injured workers to be cared for and healed in the simplest and quickest manner, medical facilities and insurance companies are often less incentivized than employers to make this happen at low costs. In fact, the businesses of hospitals and insurance companies often benefit from these incidents. Hospitals get paid for providing medical care, and insurance companies can almost always raise premiums for poor loss experience. Employers, on the other hand, are saddled with paying increased medical costs, increased premiums, employee wages, and the opportunity costs for every day of slowed or paused production due to the injured employee being in reduced capacity. Simply put, no one (except perhaps the employee) will care as much about injury recovery as the employer.

A triage nurse hotline is a very interesting way for the employer to get more post-injury control. While many people think that this benefit is only viable for larger companies, the truth is that a nurse line may be cheaper and more customizable than previously imagined. There are many companies that provide this service, but it is important to consider the philosophy and practical implementation of the two main triage styles before getting caught up in specific company brands.

Mass-Network Group

The first and more widely known setup for a triage nurse hotline is the mass-network group. Consider the following pros and cons related to the wide variety of services a mass-network group can provide:

Pros:

- 24/7 Availability: By having dozens or even hundreds of nurses sitting around computer screens, there will always be someone available to take your call. You usually reach a nurse in a matter of minutes, and this prompt response time can make all the difference quickly learning what care is needed.

- Multiple Languages: Most any injured employee, regardless of what language they speak, can relay injury information to the nurse. This is not always guaranteed at medical facilities.

- Excellent Record-Keeping: Large triage companies record everything, from injury treatment instructions to the calls themselves. If you need any information about the call, it will not be difficult to obtain.

- Third Party: These companies do not have any stake in your specific safety rules or employee relationships. When employees call in, the nurses will always advise medical care to the best of their abilities.

Cons:

- Expensive: Cost plans can vary with each company, but there is usually an annual base fee (that covers a guaranteed number of calls) with a per-call fee for every additional call. A plan like this could be expensive and therefore requires calculating the numbers very carefully.

- Different Nurses: If you call for a nurse on two different days in the same week, you will almost certainly get two different nurses. In fact, you will probably never talk to the same nurse twice. This constant change makes it difficult to build a relationship with the nurse and therefore makes it difficult to build trust.

- Registered, Not Necessarily Experienced: What does “registered” mean? Make sure you understand the answer well. If you are expecting the most seasoned soft-tissue injury specialist, you will probably be disappointed. Unfortunately, some of these nurses respond according to the on-screen prompts more than by using their education or experience.

- Third Party: Yes, this pro is also a con. These nurses are unlikely to have any interest in your specific business, which means they probably will not have any experience or understanding of your business. An employee who tells a nurse that he or she fell off an eight-foot panel into an overdig may be in for a long explanation.

- It’s Just a Call: Doctors diagnose patients by examining them in person because it is very difficult to prescribe the best treatment from a mere phone call. No matter how long the phone call is, there is a limit to how effective the diagnosis can be when the information is relayed only through words.

- Conservative: If these nurses misunderstand the gravity of an injury and prescribe less than adequate treatment, they could lose their credibility (and possibly lose a lawsuit). So, even if stitches are unnecessary, they will probably recommend stitches if they would help. Likewise, for most every fall from five feet or higher, they will likely recommend the injured employee sees a doctor due to potential head trauma.

Company-Provided On-Call Nurse

The second triage nurse hotline setup to consider is hiring a dedicated on-call nurse. This is a part-time employee you would hire to work for you on-call (whether through in-house payroll or as a subcontractor is your decision). As with the other style, there are both pros and cons to this approach:

Pros:

- Inexpensive: You set the pay at whatever amount you and your nurse agree to. Many once-nurses who are now stay-at-home moms will gladly make time for a 15-minute phone call for $30-$50.

- Consistent: When you get the same nurse every time, employees will start to grow trust in the system. This is especially beneficial for cases where follow-up calls are warranted.

- Experienced: This can be a pro if you choose your nurse wisely. For example, if most of your injuries are strains and sprains, you might want to seek out someone with experience in orthopedics.

- Industry Savvy: Even if your new nurse has never worked in construction, you can invest time and training into bringing him or her up to speed. Your employees will be impressed and more confident in your nurse’s recommendation if he or she knows what pins and wedges are, and you will be happy when the diagnosis is more accurate.

- Flexible: Maybe texting some photos of the injury would help clarify the description of the injury. If using FaceTime would make remote diagnosis easier, you could do that. You are not confined to call conversations only.

- Unbiased: This nurse should always give recommendations according to what is needed, and when there is mutual trust with the employer, the recommendations can be honest (and not just conservative for the sake of being overly safe).

Cons:

- It’s Up to You: While the pros of a privately employed nurse are essentially the reverse of the cons of using a mass-network group nurse triage, the cons of a hired nurse are largely up to the employer. For example, excellent record-keeping and 24/7 availability need to be negotiated up front (and you have to be willing to pay more for those services). However, most construction companies do not need these kinds of benefits, especially not all the time. You may be satisfied with a nurse who is only on call during your normal working hours. These logistics will be up to you.

During the current pandemic, the challenges your workforce faces when dealing with medical clinics have become even more arduous and time-consuming. On top of this, you still have to navigate workers compensation, post-injury care, claim management, liability, and all the other complex issues that come hand-in-hand with using triage nurse hotlines. While not comprehensive, this article is meant to give employers a better understanding of how to control more of the post-care process for injuries in an economy where post-care is less predictable than usual. If you have any questions regarding the potential of using a triage nurse hotline and how your company might benefit, do not hesitate to give the Concrete Foundations Association a visit (www.cfaconcretepros.org) or a call (319-895-6940), and get connected with members who use mass-network groups and members who have opted to hire a private on-call nurse.

Levi Schrock has been a featured speaker at Concrete Foundations Convention and is a regular participant in the community forums (formerly the CFA Hotline) found at www.cfaconcretepros.org. Schrock is the author of “Safety for a Residential Concrete Company,” available online on Amazon ($10). You can find more information by contacting Schrock or association staff through your member account.

Making Offices and Construction Sites Safer From the COVID-19 Virus

The current pandemic is changing the way we organize for work on construction jobsites. Along with a hardhat, safety vest, steel toed boots, and safety glasses workers must now wear a cloth face covering or an N95 respirator or equal—the new normal. Wearing a mask helps to trap tiny water droplets in your breath so that others don’t inhale them. Others wear masks to protect you when they breathe. When people exposed to the SARS-CoV-19 Virus breathe the droplets they create contain the virus particles. Photo Credit: Joe Nasvik

by Joseph Nasvik

Epluribus unum—out of many, one. This is the Latin motto the United States adopted in 1776 to signify the joining of states to form one national government. At the time, it was a difficult concept for people to accept because it meant that states and individuals would have to give up some of their personal rights to serve a greater cause. Today, the threat to life posed by the new coronavirus brings the e pluribus unum concept back into sharp focus as the country and its people consider personal rights versus one’s responsibility to others.

As social beings, this pandemic preys on our natural instincts to be close to friends and family, and it challenges our ability to work and earn a living. As time passes, it is hard to know if the first tool for fighting a pandemic — distancing ourselves from one another — is working. There is a huge number of victims, and the end is not in sight. The end, when it comes, will likely come through the development of an effective vaccine, the tool that will end the threat of the pandemic.

Construction is regarded as an essential industry in many states, and it is currently challenged to keep workers safe on the job site. “Social distancing” — the current phrase being used for keeping physical distance between people and the first line of defense — requires workers to be a minimum of six feet apart from one another. But construction, especially concrete construction, often requires teams to be much closer together for some work functions, so other safety measures become crucial. Here are some ways construction work is being made safer.

Editor’s Note: Read Concrete Facts online for information about the science behind the virus spreading.

The Tools for Fighting Pandemics

Public health professionals who focus on fighting pandemic diseases recognize four basic tools: social distancing, testing, tracing, and modeling. Keeping people separated from one another is the first major step in preventing the wide spread of the disease. Distancing has been a tactic for preventing the spread of communicable diseases for thousands of years, often by separating the diseased person from the larger group. But when it is unclear who has the disease, the first preventative measure involves isolating each person from every other person.

Developing accurate tests to quickly determine who has been infected and who has not, followed by tracing who has been in contact with who, makes it possible to quarantine only the sick. By tracing and quarantining everyone an infected person was in contact with, the spread of the disease can be limited. Iceland, for example, has tested all its citizens, quarantined those exposed, and effectively used tracing to keep COVID-19 death counts close to zero.

Editor’s Note: Read Concrete Facts online for information about modeling practices being developed.

CDC Recommendations

As a non-regulatory agency, the CDC makes recommendations that are discretionary, not mandatory. But contractors are mandated by other government agencies, such as OSHA, who use CDC’s recommendations (see CDC guidance recommendations for construction at https://www.osha.gov/SLTC/covid-19/construction.html). Unions, and sometimes construction site owners, can also require that contractors provide safe work conditions based on CDC recommendations.

Here are some useful CDC recommendations for contractors and businesses creating their own company guidelines and policies:

- Employers should have a COVID-19 response plan to protect workers.

- Workers should stay home and notify their employer if they are experiencing COVID-19 symptoms. They should not return to work until they meet the criteria determined by their employer, healthcare providers and state and local health departments.

- Workers should notify their employer if a family member living in their home has COVID-19.

- Contractors should limit contact between employees and have them maintain a minimum distance of six feet apart as much as possible. The number of workers sharing small areas — such as at construction sites, in elevators, in trailers, and in vehicles — should be limited if possible.

- Workers should wear cloth face coverings where social distancing is not possible. Cloth coverings should not be substituted for respirators where respirators are recommended or required.

- Frequently touched surfaces should be regularly cleaned and disinfected. On job sites, this includes shared tools, machines, vehicles, handrails, doorknobs, and portable toilets. Cleaning should be done periodically throughout the workday, before and after every shift, and after anyone uses your vehicle, equipment, or workstation.

- Tool sharing should be limited when possible.

- Workers should wash their hands regularly with soap and water for at least 20 seconds or use an alcohol-based hand sanitizer that is at least 60% alcohol. Contractors should supply handwashing stations with clean running water, soap, and disposable towels or conveniently placed hand sanitizer stations.

- Workers should clean their hands before and after work shifts and breaks; after blowing their nose, coughing, or sneezing; after using the restroom; before and after eating; before donning and after removing work gloves; after putting on, touching, or removing cloth face coverings; before donning or doffing eye or face protection (like safety glasses, goggles, or face shields); and after touching objects that have been handled by others.

- Use disposable tissues when you cough, sneeze, or touch your face.

- Employers should provide workers with accurate information about COVID-19, how it spreads, what the risks are, and what protective measures are in place.

- Employers should limit face-to-face contact by limiting meetings, using internet training options, and teleworking when possible.

- Employers should consider increasing the distance between employees by staggering work schedules, limiting access to work areas like trailers and break areas, rearranging tables and chairs in offices, and reducing the number of workers at meetings.

For more information, see the CDC’s guidance for businesses and employers on the website: https://www.cdc.gov/coronavirus/2019-ncov/community/guidance-business-response.html.

Cloth Face Coverings

The CDC recommends wearing cloth face coverings (see https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/diy-cloth-face-coverings.html) in public settings where other social-distancing measures are difficult to maintain, especially in areas where there is significant community-based transmission of COVID-19. When cloth masks are worn all day, or worn at a location where the wearer may have been exposed, they should be washed with soap and water before their next use.

Cloth face coverings are not surgical masks or respirators and are not appropriate substitutes in workplaces where surgical masks or respirators are recommended or required.

Personal Protection Equipment

Due to the shortage of N95 respirators, some contractors are using KN95 respirators. These are made in China and in most ways are considered equal to N95 respirators. KN95s are generally recommended for occupational use in situations that would typically require an N95. However, if you choose to buy KN95s, be careful to choose a reputable supplier, because there are products on the market that do not meet the standards they claim to meet and come with exorbitant price tags. The CDC has a recorded webinar (https://www.youtube.com/watch?v=w7tVnjrmAmc) with information about what to look for when purchasing respirators from international sources. Respirators, including N95s and KN95s, should be incorporated as part of a regular respiratory protection program (including fit testing) to protect against occupational respiratory hazards.

The primary purpose of a mask is to prevent droplets of water containing the virus from spreading. Virus particles by themselves are too small to get trapped in the mask’s filtering material. Wearing a mask protects others from inhaling contaminated water droplets expired by the wearer as he or she breathes, talks, shouts, sings, coughs, or sneezes. Others wear their masks to protect you.

N95-quality masks also offer some protection to the wearer from bioaerosols such as bacteria, some viruses, fungi, and pollen if they are fit carefully around the nose and mouth. They should be replaced when they are physically damaged, there is increased breathing resistance, or if there are other hygiene issues.

Some contractors believe that using face shields can be a substitute for breathing masks. These shields can block splashes and sprays, but they do not provide respiratory protection. Even though the shields can be easily cleaned and reused, they are not currently rated as adequate replacements for face masks or respirators. Therefore, if they are used, they should be considered an additional protection.

For more information about each of these three different tools, see the CDC infographic on facemasks and respirators at https://www.cdc.gov/niosh/npptl/pdfs/UnderstandingDifference3-508.pdf and the CDC’s information about cloth face coverings.

How One Contractor Is Making His Job Sites Safer

Mark Stadalsky, the vice president of Lindblad Construction located in Joliet, Illinois, says his company specializes in industrial concrete in several states, serving the pipeline industry, electrical power distributors, and heavy industrial companies. In Illinois, construction is considered an essential industry, so Lindblad has been able to work throughout the pandemic. Stadalsky says their team became very curious when news of the COVID-19 pandemic first appeared, and they decided it would likely become a major threat to the construction industry and their workforce. So the company’s management, safety experts, and consultants engaged in six weeks of collaborative discussions to work out a company protocol guideline with carefully defined pathways they could use to guide decisions about how to treat worker health issues. For example, if an employee called in to say he or she was ill but did not have COVID-19 symptoms, the company protocol defined a specific pathway to follow. If an employee did have COVID-19 symptoms but had not been tested, there was another defined guideline. If an employee tested positive for the COVID-19 virus, there was yet another set of procedures to follow.

Lindblad also correctly predicted early on that wearing breathing masks would become mandatory, so they bought a supply of N95 masks before they were scarce and then explored possible sources for securing a steady supply of KN95 masks. At the same time, the company hired people to make cloth masks for use by all company employees.

Some of Lindblad’s clients specify how workers on their job sites will be protected with regards to the COVID-19 virus, and Lindblad accommodates their specifications, so long as they meet Lindblad’s protocol. “For example,” Stadalsky said, “one of our clients requires workers to wear N95 or KN95 masks instead of cloth masks, so we follow their requirements.”

Lindblad protocol includes the following:

- They office staff follow a network of guidelines tailored to their duties.

- In the construction yard, everyone wears a mask.

- As much as they can, workers on job sites distance themselves from others.

- On job sites, Lindblad regularly cleans all touch points and common areas.

- They have full-time and part-time safety inspectors in the field at all times.

- During the first six weeks of the pandemic, they sent out a daily COVID-19 message designed to give workers accurate information and put them more at ease.

- They provide daily wellness checks for all employees and send them home if they have relevant symptoms.

- They are planning for the possibility of a pandemic resurgence in the fall.

A Word About Aerosols

The word “aerosol” is currently being used by the media primarily to describe the smaller droplets created when people (and animals) exhale. Aerosols are defined as droplets that are smaller than five microns in size. Anything larger than five microns is a non-aerosol droplet. All droplet sizes can contain the COVID-19 virus or other viruses.

Aerosol droplets are formed in the very small airways of the lower lung during normal breathing processes. They consist of moisture combined with mucus and surfactants, and because they are so light, they can remain airborne for several hours. This can be especially dangerous in closed environments with reduced ventilation.

Cloth face coverings can trap droplets larger than five microns, but only N95 breathing masks can trap aerosol droplets down to about one micron in size. Droplets smaller than one micron cannot be trapped by masks.

Recent research suggests that the smallest aerosol droplet sizes can contain one virus while large droplets created by rapid exhalation can carry many. There are many more small aerosol droplets created than there are larger droplets, so the risk of infection from aerosols is higher, especially because aerosols can remain airborne for so long.

2020 PROJECTS OF THE YEAR

A Crop of Excellence During a Time of Pandemic

Each year, the Concrete Foundations Association offers to its members a chance to tout their accomplishments and reward their teams for jobs well done through the annual “Projects of the Year” awards. In addition to recognizing noteworthy projects, these awards expose people to the breadth of work completed by some of the industry’s top cast-in-place concrete companies.

Among the submittals every year are projects that can be described as massive and ones that are more representative of a modest size. Members are encouraged to keep track of projects that were complex challenges and projects that leave a team taking a breath to enjoy a job well done. Additionally, the categories are revisited each year to make sure there are openings appropriate for recognizing any new, diverse applications, which tend to showcase the creative growth of the cast-in-place concrete industry.

Formerly known as “The Basement From Hell,” the Association initiated this program under the direction of the long-time executive director, Ed Sauter. “Quite frankly, we initiated this program as a way of helping give annual marketing content to the Association,” Sauter said. “‘The Basement From Hell’ was coined to represent some truly remarkable, and at times monstrous, projects that challenged member companies the most.”

Each year, the top project was determined based on how challenging it was to estimate, build, and achieve some measure of profitability. This changed over time as project variety grew. “Today, contractor members of this Association are experts in residential and commercial foundations; they are taking on industrial slabs, tilt-up buildings, post-tensioned foundations, above-grade homes, and multi-family complexes,” said executive director for the CFA, James Baty. “As we have advanced the program, contractors have continued to ask us whether a project of one type or another would fit. This has resulted in broadening our categories to where, today, we have eight different categories and annually award at least half of them.”

The following pages represent this year’s awarded projects, selected for the first time in several years by popular vote by Association members. During #CFAAtTheEcho, participants had an opportunity to roam the Showcase Pavilion and watch three-minute videos about each project. After this, each project had a quick five-question survey with a point and click rating scale. This was an opportunity for the industry to come together to give contractors a chance to display their very best, and a chance to participate collaboratively in recognizing truly unique accomplishments.

______________________________________________________________________________

OVERALL GRAND PROJECT OF THE YEAR

Single-Family Residential Foundation Over 5,000 sq. ft.

SABO IN NEWPORT BEACH, CALIFORNIA

Member Since 2006

This project, nicknamed “Sabo,” is the type of job that would put many companies out of business if they did not know what they were doing. The project seems to have everything: caissons, shoring, mat slab, battered shotcrete walls, waterproofing, radius poured-in-place walls, outrageous rebar details, two pan decks with lightweight concrete, a radius driveway deck (above grade), waterproofing concrete additives, and epoxy-coated rebar.

The project’s footprint is 9,000 square feet, and its material details are incredible, with over 2,400 cubic yards of concrete, including over 1,100 yards each in the mat slab and caissons. There is 910,000 pounds of steel reinforcement, with 720,000 pounds in the caissons alone. Basement wall heights ranged from 11 to 26 feet and the wall thicknesses range from 12 to 18 inches.

“While gathering all of the data and information for this submission, I was left feeling very content with the amount of teamwork performed at Ekedal in a highly efficient manner,” stated Ryan Ekedal, president of Ekedal Concrete.

Rather than using traditional footings, this project has a 15,000-square-foot, 30-inch-thick mat slab. The slab features two layers of #6 reinforcement bars at 9-inch spacing each way, and all rebar was epoxy coated due to the proximity of the ocean below.

Since the project sits right on the bay front in Newport Beach and consists of a 9,000-square-foot basement foundation with the bottom of the slab sitting at 17 feet below sea level, we had to install a shoring and dewatering system. We drilled 109 30-inch caissons with a combined drilling depth of 6,000 feet. This was followed by the installation of a “secant” soldier pile system that used interlocked hard and soft piles, eliminating the need for the more common lagging technique used on shoring projects not in the water table. The reinforcing steel cages were over 48 feet long, each with eighteen #9 verticals with ties.

Once the caissons were drilled and poured, 17 “well points” with 18-inch diameters were drilled 50 feet deep, creating a dewatering system that brought the water table below the bottom elevation of the mat slab. This dewatering went on for six months.

The mat slab was used in lieu of footings, since the elevation is 17 feet below sea level. Once completed, the rest of the complex foundation, with curved walls and other architectural features, could progress.

“Receiving this award is such an honor, as it is voted on by my peers in the industry, which means a lot,” states Ekedal. “We try to deliver such an amazing experience to all of our clients, and to be acknowledged for this great work we are able to provide feels great! At Ekedal, we love concrete and the opportunities of building the impossible, so for other amazing people and companies in the industry to appreciate that is huge! This speaks volumes to the culture which is vital to the success and/or failures of a project or company. I try to always ensure the culture at Ekedal is one where all the employees know the mission and have the same goals and desire to be the best!”

______________________________________________________________________________

SINGLE-FAMILY RESIDENTIAL FOUNDATION 2-5k SQ. FT.

Private Residence in Atlanta, Georgia

HERBERT CONSTRUCTION COMPANY, MARIETTA, GEORGIA

Member Since 1992

This project required considerable custom-built features. There were seven phases, each with its own estimate, and the company had to deal with bad soil (which had to be removed and replaced with stone) and install retaining walls to build up the road for access before beginning the foundation proper.

A total of 830 linear feet frame this 4,169-square-foot plan. The project required 562 cubic yards of concrete and over 56,000 pounds of steel. Wall heights stepped a total of eleven times (from 2 feet up to 15 feet) for five wall thicknesses (from 8 to 16 inches).

The phases of construction were carefully planned so as to keep the site and the complicated design under control. The first phase saw the construction of a 14-inch-thick by 4-foot-tall wall made for the pool with multiple radius walls. During phases two and three, two retaining walls were built — these were required for site access and for building the roadway up. One wall had a 106-foot radius with a heavy design and 378 vertical feet of radius corners, the other wall was 16 inches thick and 16 feet tall with a radius section sloping 13 feet downward to 7 feet.

Phase four was constructing the main basement walls, which were 11 feet tall and approximately 400 linear feet.

In phase five, the basement slab, thickened to six inches in some areas with additional reinforcing and helical piers due to poor soil conditions, totaled 3,770 square feet with a double-mat grid of #5 rebar.

The sixth phase consisted of building arched walls and footings for the back patio area. In all, 16 arched openings of six different sizes were placed in walls from 12 inches to 16 inches in thickness. The custom-built arched wood blockouts were crafted from Luan plywood to ensure a smooth finish, and seven beam pockets were included to hold I-beams for the covered patio above.

The final phase, phase seven, saw the installation of a retaining wall designed to build up the site for a driveway and to create a walkway to the basement level. This wall sloped from 4 feet to 12 feet tall.

This job required technical elevations because of jumps and radius walls. The arched openings did not have an assigned set radius, so, through trial and error, the arch was determined using CAD. Combined with the rest of our station, the result was unmatched accuracy.

______________________________________________________________________________

SINGLE-FAMILY RESIDENTIAL FOUNDATION < 2k SQ. FT.

Sweetwater Lake in Ninevah, Indiana

CUSTOM CONCRETE OF WESTFIELD, INDIANA

Member Since 1986

With a name like Sweetwater Lake, it should not come as a surprise that this project is located on a lake lot in southern Indiana, which is known for hard shale and limestone. The lot had a substantial amount of fall toward the lake, and the owner was hoping to save a portion of the lot’s pre-existing block basement foundation. The original plan was to add to the front of this existing basement.

This small footprint only enclosed 1,840 square feet, and in only 346 linear feet of wall, the wall stepped thirteen times from 1 foot up to 19 feet and 8 inches. Wall thicknesses were 8, 10, and 12 inches for a total concrete volume of 136 cubic yards with 8,257 pounds of steel.

Due to county building code requirements, the original foundation could not be kept, so we moved into demolition and hauled materials off site. When we proceeded with excavation, we soon encountered hard shale and limestone, which required a large excavator with a hammer. This unexpected obstacle greatly slowed down the project’s excavation phase.

In order to maintain access on the small lot throughout construction, we left off the garage foundation until the end of the project, facilitating access for our form delivery truck cranes, concrete pumps, and gravel conveyors. Adding to the challenge, the existing gravel drive was steep and tight for large trucks and equipment. When the walls were finally poured and stripped, the gravel conveyed, and the basement slab poured, we proceeded to add the attached garage foundation, which required 12-by-16-inch-tall retaining walls.

The walk-out basement included nearly 200 feet of 24-by-12-inch footings with #5 dowels that were 12 inches o.c., all installed on limestone rock. The extreme terrain made navigating and forming these footings difficult, but with CAD and total station layout, we were able to install these footings with precision.

As mentioned earlier, our walls stepped 13 times, ranging from 19 feet and 8 inches tall to 1 foot tall. To retain the high upper grade despite the severe fall of the grade toward the lake, we had to pour a wall that was 12 inches by 19 feet and 8 inches at the front of the lot as a part of the basement wall. This wall extended up through the first floor, supporting the second-floor system. We worked with the framer to establish the correct wall height. The wall then stepped with the grade from 19 feet and 8 inches down to 9 feet; we kept that height through the fireplace and then stepped down further to 5 feet for the “four seasons” room. The garage’s side walls stepped from 19 feet and 8 inches down to a 16-foot common wall and then down to 9 feet. The walls continued at this height to a large window and concluded at the “four seasons” room.

This property overlooks a beautiful lake, so it is no surprise that the owners wanted to take full advantage of the view. With an abundance of topographical fall, we were able to install this walk-out basement to complement the lot’s terrain and the view.

______________________________________________________________________________

ABOVE-GRADE ALL-CONCRETE SINGLE-FAMILY RESIDENCE

North Tropical on the Intercoastal Waterway, Florida

TCB WALLS INC. OF MELBOURNE, FLORIDA

Member Since 2019

This above-grade concrete home was built in the state of Florida, where a reliable market is developing for the durability and security realized with all-concrete shells.

This job had a little bit of everything going on, and no single aspect was considered out of the ordinary. However, combining so many complicated items in one job made the project more unique in scope. The project consists of over 1,300 total linear feet of concrete wall throughout its 15,000-square-foot footprint, and the project totaled over 380 cubic yards of concrete.

The desire was for a stormproof “bunker” that would also provide protection from other potential threats. “It’s what we do, and we were involved from the initial conceptual drawings,” said Timothy Ball, president of TCB Walls Inc. “Extensive time was spent prior to each phase to allow the crews to run them smoothly.” This included working diligently and meticulously to have all questions answered and all info in hand before sending a crew out to start a phase.

One of the special materials incorporated in the project was helix-twisted micro-steel reinforcement (TSMR), which was used extensively in the structural design. MMFX rebar was used in the structural decks around the entire structure to mitigate future corrosion issues, since the project is located on an intercoastal waterway in a saltwater environment. All concrete on the project used a high-early 5,000-psi mix, and all 28-day breaks came in around 8,000 psi.

The use of a lull with personnel baskets and cranes was vital to being able to reach some of the places on this project, as there were access restrictions protecting trees (some of which are over 100 years old) growing all around the project area.

“It is just really cool for a small company like us to be recognized for all our hard work on a national platform,” said Ball. “I feel like all the members of our team will be even more proud of the work that we do than normal. It’s going to be something for all our employees to talk about with other trades and competitors. I believe this award will elevate the project locally for our customer as well.”

______________________________________________________________________________

COMMERCIAL FOUNDATION STRUCTURE

Crossover Work Foundation

CUSTOM CONCRETE OF WESTFIELD, INDIANA

Member Since 1986

This commercial structure project is the first industrial project undertaken by Custom Concrete. The move into this market segment challenged the team, both from a scheduling perspective and a safety perspective. The team drew from experience from past projects to help them successfully handle the challenges created by scheduling and access. Relying on the general contractor gave them confidence and understanding in managing all safety requirements.

Although small — just over 1,100 square feet — this project consisted of more than 600 cubic yards of concrete and 35 tons of steel reinforcement. The footings alone had over 6 tons, consisting of #8 and #10 bars. The cast-in-place walls were 8 feet tall, some of them at 12 and 16 inches in thickness.

The most significant challenge in this project’s construction was the restricted access. All deliveries were managed through security checks, and only the daily usage was permitted on site — no schedule storage was permitted. Since the equipment for handling the materials could not be used near the installation site, the location complicated the installation of steel reinforcement, requiring most of the 35 tons to be hand-delivered down into the forming. This distance also meant that all forming baskets had to be placed into the hole using a large crane. Most of the concrete was placed under roof at a considerable distance from safe access. Our team devised a plan to use two concrete pumps set in tandem, so deliveries to one could be pumped to the next and then on to the placement positions.

The pad itself was complicated at 24 inches in thickness with double-mat reinforcement. The placement alone was time-consuming and tedious. This pad required nearly 300 inertia blocks, each isolated using 4-inch foam with 1.5-inch gaps on both sides created using ¾-inch plywood. As this was an industrial foundation project, accuracy was critical for both the footing and the finished wall elevations. Angle iron was embedded around the entire interior perimeter at the seam where the wall meets the ceiling. Coordinating this with a general contractor whose schedule was much different from ours required careful communication to set expectations and manage conflict resolution.

______________________________________________________________________________

The Best of the Rest

With a near record number of entries this year, including a whopping 11 projects in the over-5,000-square-foot category, many great works of cast-in-place concrete were recognized by the participants evaluating the entries. This year, seven honorable mentions were also selected. These included:

ABOVE-GRADE CONCRETE HOME

Main Street Residence

PURINTON BUILDERS INC., EAST GRANBY, CONNECTICUT

Member Since 1999

______________________________________________________________________________

SINGLE-FAMILY RESIDENTIAL FOUNDATION, 2,000 TO 5,000 SQ. FT.

I-4 Chatham Hills

CUSTOM CONCRETE, WESTFIELD, INDIANA

Member Since 1986

K-83 Chatham Hills

CUSTOM CONCRETE, WESTFIELD, INDIANA

Member Since 1986

______________________________________________________________________________

SINGLE-FAMILY RESIDENTIAL FOUNDATION, OVER 5,000 SQ. FT.

Cook Residence

SCW FOOTINGS & FOUNDATIONS, SALT LAKE CITY, UTAH

Member Since 1978

Victory Ranch Lot #202

SCW Footings & Foundations, Salt Lake City, Utah

Member Since 1978

Private Residence

HERBERT CONSTRUCTION COMPANY, MARIETTA, GEORGIA

Member Since 1992

Deer Crossing Lot #33

SCW FOOTINGS & FOUNDATIONS, SALT LAKE CITY, UTAH

Member Since 1978