OSHA UPDATE: NEW REPORTING REQUIREMENTS STARTED JANUARY 1ST

As of January 1, 2015, there is a change to what covered employers are required to report to the Occupational Safety and Health Administration. Employers are now required to report all work related fatalities within 8 hours and all in-patient hospitalizations, amputations, and losses of an eye within 24 hours of finding about the incident.

Previously, employers were required to report all workplace fatalities and when three or more workers were hospitalized in the same incident. The updated reporting requirements are not simply paperwork but have a lifeIsaving purpose: they will enable employers and workers to prevent future injuries by identifying and eliminating the most serious workplace hazards.

Employers have three options for reporting these severe incidents to OSHA. They can call their nearest area office during normal business hours, call the 24 hour OSHA hotline at 1-800-321-OSHA (1-I800-321-6742), or they can report online at www.osha.gov/report_online. For more information and resources, including a new YouTube video, visit OSHA’s webpage on the updated reporting requirements.

Beating the Boomer Bust

YOU CAN’T CHANGE THE FACTORS THAT CREATE THE MOST COMPETITIVE SELLING ENVIRONMENT IN HISTORY. UNDERSTANDING WHAT THE FUTURE LOOKS LIKE IS A CRITICAL FIRST STEP IN THE PROCESS.

By John F. Dini

More than 60% of US business owners are over 50 years old, and many of them are looking toward retirement and the process of attracting and vetting potential buyers to take the reins. The differences in yesterday’s and today’s business landscapes are stark—as Boomers were raised in a highly competitive environment, many face the problem of having built companies that won’t attract a new generation of buyers. Three major trends impact the salability of a business. Understanding these trends can help owners transition successfully in a challenging market, and ultimately identify the buyer who will carry their company’s torch going forward.

WHY DO BOOMERS WORK SO HARD?

Baby Boomers are 2 1/2 times more likely to own a business than the generations before or following. Between 1975 (when the first Boomers turned 30), and 1986 the formation of new businesses in America jumped from 300,000 to 700,000 annually. Faced with fierce competition on the pathway to success, many Boomers chose to chase the brass ring by going into business for themselves. New business start-ups have never again reached that level. The result is that nearly two-thirds of all businesses with fewer than 500 employees are in the hands of people who are preparing to retire.

The impact of the Baby Boomers at each stage of life created a one-time surge in many statistics. They tripled the number of college graduates, and brought over 50 million women into the workforce. Between 1970 and 1980 the population of the United States increased by 11%, but the employment base grew by an astonishing 29%. Replacing such a massive portion of the population in the business sector is no easy feat.

THE PERFECT STORM

There are three major trends that challenge a small business owner preparing to exit. Like the movie “The Perfect Storm,” these three trends; demographic, psychographic and sociographic, are combining to create a Tsunami that will change the entire landscape of independent business ownership.

- Demographically, the generation following the Boomers (Gen X) is much smaller. From a supply and demand perspective, there simply aren’t as many available buyers as the number of potential retirees seeking them.

- The psychographic profile of the buyer generation is unfavorable. What business owner hasn’t complained about the work ethic of the younger generation? Raised in a forty year period of economic growth (the longest sustained period of expansion in our history) Generation X and their successors (The Millennials) are more likely to choose family first, and perceive jobs and employers as merely the means to a personal end.

They aren’t wrong. The parents of the Boomers’ understood the difference between work and personal life. One started when the other ended. In their drive for success, the Baby Boomers mixed the two and created the term “work/life balance”. Younger generations are actually returning to an older set of values.

- Sociographic trends favor alternative careers over business ownership. Corporate America is well aware of the issues and attitudes of the younger generations. They have already made many adjustments. Telecommuting, sabbaticals, family leave, and flex time are benefits designed to attract younger workers who have a different set of priorities. Few small businesses have the depth or breadth to allow skilled employees to come and go according to their individual priorities.

Young entrepreneurs have little interest in the service-oriented brick-and-mortar companies that dominate small business. They seek a level of freedom that doesn’t require being on call, schedules driven by customer convenience, or a 55 hour work week. Combined with the sheer lack of prospective buyers, a reduction in the number of small businesses becomes more than likely, it is inevitable.

Yet, many small business owners are depending on their company to fund a comfortable retirement. Their plan goes something like this: “I will work really hard until I am tired, and then I will find some energetic younger person just like me who is willing to commit everything for this great opportunity.”

BEATING THE ODDS

Fortunately, if you are a successful business owner, you’ve already proven your competitive instincts and abilities. With some planning and foresight, you can still beat the Boomer Bust and achieve your retirement objectives. There are two pathways to succeeding in a crowded sales marketplace.

- BUILD TO SELL

Your first option is to build a business that is attractive to your younger buyers. It allows for personal flexibility. It can’t require a huge down payment, since these generations were raised in a “buy-now-pay-later” world, where they are carrying substantial debt from the day they graduate college, and have little opportunity to amass liquidity.

Your technology doesn’t have to be cutting edge, but it needs to be current. Nothing turns off the tech-savvy young buyer faster than a company that is limping along on outdated software or (heaven forbid) paper. Of course, the other attributes of an attractive acquisition; growing margins, a distributed customer base and predictable revenues, are a given.

- HIRE YOUR BUYER

The second option is to hire your buyer. The stereotypes of different generations aren’t universal. Certainly we all know Boomer slackers, as well as young people who are ambitious and hard-working. Lacking capital, many of those younger go-getters would like to own a business but have difficulty seeing how they can make it possible. Identifying such a buyer in your own organization, or even reaching outside and recruiting one, is a viable option if your target date for exiting is a few years away.

Creating your own successor requires a commitment to planning and development, but the financial aspects are fairly simple. A few years of selling equity in small amounts can let your successor build a minority stake. Then he or she can obtain third-party financing for the balance of the purchase so you can maintain control through the process, and take the proceeds with you when you leave.

Remember; “The more you work in your business, the less it is worth.” Everything you do to reduce your business’s dependence on your personal talents, to reduce the time commitment of running it, and to make it easier for any successor (whether internal or external) to take over the reins, also increases its value to any buyer.

You can’t change the factors that create the most competitive selling environment in history. Understanding what the future looks like, and realizing that your buyer is unlikely to be someone “just like me” is a critical first step in the process.

John F. Dini is a coach, consultant and author of the award-winning book Hunting in a Farmer’s World, Celebrating the Mind of an Entrepreneur and Beating the Boomer Bust. Widely recognized as one of the nation’s leading experts on business ownership, John has delivered over 10,000 hours of face-to-face, personal advice to entrepreneurs. For more information on John F. Dini, please visit www.johnfdini.com.

Setting A New Standard for Leadership

CFA Professional Awards

CFA BOARD OF DIRECTORS BESTOWS THEIR HIGHEST HONOR ON DOUG STAEBLER OF CUSTOM CONCRETE, INDIANAPOLIS, INDIANA.

The Robert D. Sawyer Award is named for the CFA’s first Executive Director, whose commitment and diligence wove together a vital network of information, experience and togetherness that has perpetuated to shape the future of this industry. The award recognizes individuals who commit countless time and resources to serve the industry, and is presented to a contractor member whose contributions to the industry merit such recognition. “Bob’s inspiration and leadership brought together a group of minds truly focused at improving the technology and practices in an industry that we love so much,” states retiring Executive Director, Ed Sauter. “He will not be forgotten.”

The Board of Directors honored nearly two decades of educational contribution to business development by Custom Concrete’s Chief Financial Officer, Doug Staebler this past summer. Known for his thought-provoking and carefully researched topics on all aspects of running the complex structure of a cast-in-place concrete contracting company, Doug has been a featured keynote at the CFA Annual Convention and has had a large impact on many companies.

“As I met more members during and after presentations at Convention,” stated Doug, “I came to realize that most CFA contractors did not have CFOs or controllers, and relied on outside CPAs for financial matters. I also began to realize that outside accountants have very little appreciation for or experience with many of the issues and challenges that we face in our businesses. I began to focus on financial aspects of managing a contracting business and how our specific industry experiences, both good and bad, could be helpful to many other contractors. Prior to joining Custom Concrete, I spent 14 years in public accounting working with closely held businesses and their owners, so it seemed natural to develop presentations that could be helpful for other companies.”

We asked Doug what the legacy of Bob Sawyer means in this award? “Unfortunately, I only met Bob on a few occasions in my first few years attending the CFA summer meetings, but it was immediately apparent the impact that Bob had on our industry. As I became more familiar with the history of CFA, I learned that his tremendous vision and leadership were instrumental in forming the CFA. He was tireless in his efforts to build the Association. I was struck by the tremendous respect and appreciation that was held throughout the organization for Bob. Most of all, I remember that he spent immense effort and time to help other contractors in their business and to build an effective organization. Bob was a pioneer in our industry and was interested in everyone’s success, and the Bob Sawyer award is very meaningful and humbling to me.”

Bob Sawyer recipients all demonstrate an unselfish application of themselves to a multitude of efforts and peers. We asked Doug to consider those coming before him in this award and in light of it, what has compelled him to participate in the CFA, offering his experience, energy and leadership for so many years?

“When I first met Joe Carr and began working with Custom Concrete as the company’s outside CPA, I was amazed at the combination of hard work and high ethical standards, together with a desire to build a business that created opportunities for so many people,” stated Doug. “In my first experiences with CFA, I met many like-minded individuals. It was very clear to me that these were special people who invested everything into their businesses with incredible passion and vision. I quickly came to realize that most of these companies faced the same challenges as we did, and I wanted to share some of our experiences that could be helpful to others. I quickly saw that sharing our experiences allows all of us to grow and develop our businesses with the benefit of hands on experience and knowledge of other contractors.”

“I have truly enjoyed the great opportunities to get to know so many great people in the CFA. This is a great group of hard working entrepreneurs who perform difficult work on a daily basis and have a real passion for building their business and creating opportunities for their employees. There have been many great times over the years and I have truly enjoyed the relationships that have developed over the years.”

“It is always a proud moment for the CFA to be able to recognize a leader that has done so much and can be attributed for significant changes and improvements in the company strategies for so many,” states Barry Herbert of Herbert Construction, chair for the CFA Nominating Committee. “This award is not given very frequently so that the integrity of the award as our highest honor is maintained. Being able to recognize Doug in this way is very fitting for the hand he has played in the strength of the CFA network.”

We encourage congratulations to him at dougs@customconcrete.com.

Perseverance in the Face of Adversity

CFA Professional Awards

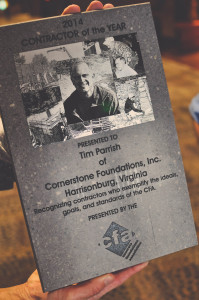

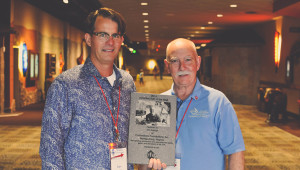

CFA RECOGNIZES TIM PARRISH, FORMERLY OF CORNERSTONE FOUNDATIONS AND NOW CFI ENTERPRISES, AS CONTRACTOR OF THE YEAR

The most frequently awarded recognition for individuals from the CFA is the Contractor of the Year award. This recognizes the contributions of a poured wall contractor to the industry and often evidences the excessive efforts they make beyond their company’s location and position in order to benefit the greater goals of the Association and the industry as a whole. In recognition of the annualized character of this award, this award seeks to find one of the Association’s leaders that truly exceed their own expectations and that of the average member.

At Annual Convention this year, the Board of Directors presented Tim Parrish with this prestigious honor. “Tim has exemplified the passion and energy of this Association during a time period where life has thrown just about everything possible at him,” states Jim Bartley, CFA Past President and Chairman of the Board. Physically disabled and bed-ridden most of the time due to the untreatable condition known now as chronic pain syndrome, Tim has poured himself into the CFA. He fully completed his commitment as a Board member via correspondence and several times sitting through the four-hour or so meetings on conference systems. Most recently, he and his wife traveled the two hours to Washington DC, though retired from the Board, just to have another chance to be part of the meeting. His commitment has extended into investing time and funds in the insurance captive formation effort, also serving as one of four steering members working intimately with the captive manage consultants and CFA staff.

Friend and peer, Dan Bromley (left) accepts the award for Parrish during the 2014 Convention alongside Ed Sauter, Executive Director.

Considering the future of the CFA, however, Tim has been perhaps most impressive serving as a mentor for new CFA members. He has frequently contacted new companies as they are announced and willingly invited them to a visit to his company as well as communicating with them to better understand their businesses. Through this mentorship effort, Tim has exemplified what the CFA Board has felt will be the future for this industry.

Contractor of the Year, however, is not an endorsement simply of the service to the CFA as it also must evidence industry leadership and performance of the company as part of the bigger picture. Here Tim has continued to labor and continued to succeed. During a time when his active involvement has been thwarted by the debilitating condition he endures, Tim has managed to gently and enthusiastically encourage his company leaders to step up and step forward. They have continued the success of his legacy. Together with his wife, Donna, they have maintained Cornerstone Foundations as a regional leader and a cutting edge concrete professional organization. That company now sets off toward a promising future under new ownership while the Parrishes take on a new venture in concrete pumping with CFI Enterprises, a new CFA member.

While Tim was honored and recognized during the Convention in Ohio this past summer, you are encouraged to send him a message of hope and gratitude.

Tim can be reached at tim@cfient.com.

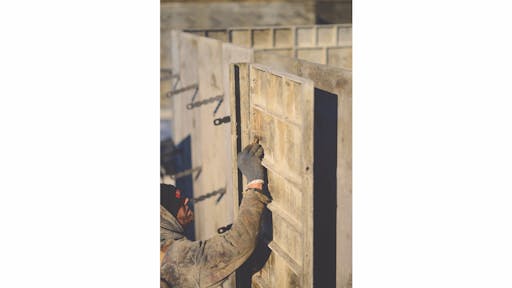

CFA Undertakes Industry Survey on Cold Weather Practices

ACI Committee 306 and the Concrete Foundations Association are committed to improving the conditions for directing and implementing state-of-the-art technology for better performance in cold weather concreting. The combination of professional contractor experience and this technology is proving the production of quality concrete at a broad range of placement and curing temperatures and conditions.

A survey has been created to gather information of present practice and guidance for the provisions and applications of cold weather concreting. Access this survey by visiting http://ow.ly/Ghu7b or by visiting CFA’s booth #4341 at World of Concrete.

“Our interest is to continue redefining the ideas associated with cold weather performance of concrete and the prediction of protection needs,” states Dennis Purinton, CFA member and president of Purinton Builders in East Granby, CT. Dennis has led the most recent research efforts for cold weather performance looking at new wall behaviors and slabs. “While we continue to research the impact our decisions for mix design, production and placement conditions and protection measures have on our concrete elements, we also need to assess the information being used for guidance and assure that the industry has ways to cost-effectively and efficiently implement practical measures.”

Survey participants to the CFA booth at WOC will be entered into a drawing for a free iPad mini donated by Wacker Neuson Production America LLC and a commemorative CFA ball cap while supplies last.

Now is the time to clean out the spray unit tank!

Kim Terry’s tips, techniques and practices for waterproofing contractors.

Maintaining equipment operation using a flushing process:

No doubt about it using asphalt products can be quite frustrating at the least and at worst complete shutdown of the spray unit costing hundreds of dollars in loss time, not to mention a possible customer lost when a job can not get done because the spray unit is down. What many contractors fail to realize is that asphalt emulsions build up over time in the tank, hoses, heat ex-changers etc, so I am going to suggest a practice that will help to reduce the headaches and down time if these procedures are followed.

Remember what Benjamin Franklin said “An ounce of prevention is worth a pound of cure.“

Annual to Bi-annually flush the unit: Winter time is particularly a good opportunity to perform flushing procedure; Here is the procedure.

- Clean the tank of all asphalt, as much as can be sprayed out or drained out, and put in an old drum if you can’t do it on a foundation

- Put 10 gallons of diesel fuel in the asphalt tank, this is usually enough to allow re-circulation.

- Turn on the spray pump on low and recirculate the fuel/asphalt for 1-2 hour minimum with the truck running, and the heat ex-changer on.

- Take the gun off of the hose and run the hot fuel through the hose for about 15-20 mins at the end of the session.

- After complete, put the fuel/asphalt mixture into a drum that can be used for later flushing.

- Load truck as normal, there will be a little fuel/asphalt in the tank and lines but this will not impact the application.

- Spray the fuel/asphalt into the drum until no more comes out prior to going to job site. Any fuel in the tank will mix with the asphalt emulsion and just provide easier spraying This process cleans out all components of the spray system including the tank. Your spray crew have less hassles this winter and it will improve performance of the unit.

Understanding Concrete Maturity for Curing Cold Weather Concrete Pours

Originally published by Concrete Contractor Magazine, a ForConstructionPros publication on December 22, 2014

by James R. Baty II, F.ACI, F.TCA

Question: The onset of cold weather has complicated our project schedules tremendously. One of the municipalities we work in is requiring us to leave forms on the wall for three days and telling us to rent wood forms instead of using our aluminum forms when the temperature is below 32-degrees Fahrenheidt. Are these arbitrary conservative precautions or are their concerns valid? Our customer schedules are suffering due to these requirements.

Answer: Cold weather is certainly the time of the year that becomes most concerning to the consumer and the inspector in the construction industry. The simple act of having to add layers to the body translates to an immediate concern for the placement of concrete and what might happen to a process that involves water, which obviously must freeze. ACI 306 is largely considered to be the most appropriate resource for determining a position for concrete construction and yet, this document that is a guide or a compilation of recommended practices, is perhaps the most misunderstood of technical references.

ACI 306 has the challenge of representing an entire industry, all variables and conditions and delivering practicable methods for protecting the ultimate goal, concrete maturity. So then, what is the market to do when it does not have the time to investigate the specific conditions realistic to the application? This is where the selection of overly conservative parameters occurs and often from resources that are built upon other conservative decisions and not research or science.

My recommendations are to build a conversation and an approach based on the research completed specifically for residential foundations, research that demonstrates a rational approach to cold weather concrete maturity. CFA’s Cold Weather Research Report 2004describes the impact of sub-freezing laboratory and field temperature conditions on concrete maturity. This report is a reference included in both ACI 306 and the residential concrete code document, ACI 332 and provides a much more effective set of guidelines for your market.

Fact: The freezing point of concrete is not an air temperature of 32-degrees Fahrenheidt. This is supported in part because concrete is a physical composition of more than just water. However, the primary support for this fact is that once a concrete mix is made, it immediately begins a chemical reaction with a by-product of heat. The generated heat elevates the material temperature of the mix and continues to do so as the chemical process continues. This is a counter balance to the chilling effects of the ambient air condition and a benefit to the construction process.

Fact: A concrete mix can achieve sufficient strength for protection and self-support under cold weather conditions in 24 hours or less. The primary benefit of the CFA’s research is the recognition of mix design performance for delivering varying levels of strength or concrete maturity based on temperature conditions, time durations and mix economies.ADVERTISING

ACI 347, “Guide to Formwork for Concrete” states in section 3:

“Determination of the time of form removal should be based on the resulting effect on the concrete. When forms are stripped there should be no excessive deflection or distortion and no evidence of damage to the concrete due to either removal of support or to the stripping operation (Fig. 3.5). When forms are removed before the specified curing is completed, measures should be taken to continue the curing and provide adequate thermal protection for the concrete.

So the contractor has the duty of removing forms when the concrete can be self-supporting. That is a measure of concrete maturity and research can be used to demonstrate or correlate the performance of a selected mix design to the targeted anticipated temperature ranges. Furthermore, research further supports the nature of a concrete mix achieving strength to withstand the impact of freezing without impacting durability and return to strength gain once freezing conditions subside or supplemental curing conditions are established.“

Fact: A bigger risk for residential foundations is the open exposure of the excavated grade to freezing conditions than the exposure of the concrete. Soil temperature is critical to the protection from frost and heave. Excavations that remain open for significant time schedules will experience abnormal levels of frost development and heaving or pressure from the expansion of naturally occurring moisture. Therefore, the concrete contractor must work with the ready mix producer to have a mix capable of reaching self-supporting strength (a strength just beyond final set or 500 psi) so that forms can be removed, the wall braced or floor deck installed and the backfill process initiated. Leaving the excavation open for days with forms still on the walls only increases the true risk to the foundation created by abnormal soil pressures due to freezing.

Fact: Short-term protection is beneficial. CFA’s research shows the contractor can find some great benefits in making practical decisions early in the construction process. These include pouring earlier in the day; using blankets along the top of the wall in the 20s and full blankets in lower ranges; and maintaining a strict adherence to the w/cm. These all impact the behavior of the concrete mix designs toward the goals of developed maturity.

Fact: The forming system will have little impact on the concrete temperature. Although insulated concrete forms will bring a measure of blanketed protection to the curing condition of concrete, all other forming systems have little impact on the practical concrete maturity. A concrete mix design targeted to permit forms to be removed in one-day means that concrete temperatures will remain elevated beyond the impact of surface temperature exposure. Wood, aluminum and steel forming systems are not capable of delivering insulating properties significant enough to perform as insulators for the temperature conditions being considered here. Therefore, basing curing protection on the decision of one of these over another only falsifies the protection condition being assumed.

The best solution for cold weather concrete work is to know your mix design performance, become informed of the research that supports the prediction and monitoring of concrete performance and understanding the options for temperature ranges that ensure the best balance of maturity, schedule and economy. The CFA offers education in the form of webinars and regional classes that can help concrete professionals and municipalities come together to provide assurance for quality concrete.

Ed. Note: Jim Baty is the Executive Director for the Concrete Foundations Association after having served as Technical Director since 2001. He is currently chair of ACI 332 and a voting member for ACI 306 with priorities of establishing better guidance and structure for residential concrete construction. For more information on this topic, contact Jim Baty at jbaty@cfaconcretepros.org. Find out more at www.cfaconcretepros.org.

Los Angeles Blaze Calls Building Codes into Question

Concrete Industry Opposes Further Relaxing of Codes

SKOKIE, Ill.— The fire that ruined buildings and snarled traffic in downtown Los Angeles this week may not have happened ten years ago. However, loosening of the building codes and the increasing importance on low-cost construction is putting Los Angeles and other areas at risk.

“Taller and larger wood buildings are part of trend to relax fire protection provisions in building design and construction to reduce costs,” says Stephen S. Szoke, PCA senior director of codes and standards. “It saves on initial costs by using cheaper building construction than traditional non-combustible materials such as concrete, masonry or steel and puts buildings under construction at a greater risk of fire.”

Taller and larger wood buildings are part of trend to relax fire protection provisions in building design and construction to reduce costs.

The model building code used as the basis for most city and state building codes is the International Code Council International Building Code. The 2012 edition of the IBC, limits the height of load-bearing combustible construction to four stories for residential construction. A building using load-bearing walls of combustible wood construction can have a total height of five stories if the building is sprinklered and at least the first floor is constructed of fire resistance rated noncombustible construction, such as concrete or masonry. But, a sprinkler requirement cannot protect the building and structures around if a fire breaks out during construction.

Structures built with non-combustible materials prevent the spread of fire, even when a sprinkler system fails – as can happen in an earthquake or when a building is still under construction and the sprinkler system has not yet been installed. In 2007 when construction was at an all-time high, the most common form of five- and six-story residential construction used load-bearing concrete masonry walls with precast concrete floors.

“Common sense shows that buildings build of non-combustible materials are not the same risk of fire damage,” says Szoke. “According to a recent National Fire Protection Association report during a five-year span, departments responded to nearly 830 construction fires. Aftermath pictures routinely show that it is only the wood portion that burned away. Concrete staircases and elevator shafts are still intact. The Los Angeles fire only caused structural damage. If codes are not changed, the next one could cause loss of life.”

About PCA

Based in Washington, D.C., with offices in Skokie, Illinois, the Portland Cement Association represents cement companies in the United States. It conducts market development, engineering, research, education, and public affairs programs. More information on PCA programs is available at www.cement.org.

Crane Operator Skills Competition at WOC

Crane Operator Skills Competition to be featured as World of Concrete Outdoor Event

November 25, 2014 (Sanford, Fla.) — In cooperation with the 2015 World of Concrete show, Crane Institute Companies, CIC and Crane Institute of America, will bring two crane operator skills competitions to commercial concrete and masonry contractors, Feb. 3-5, 2015 in Las Vegas, Nev.

Making its debut is a Knuckleboom Crane Operator Challenge, which draws its skills assessment criteria from Crane Institute Certification’s articulating boom crane certification. Three knuckleboom crane operators—one each day of the Outdoor Gold Lot Events—will win cash and other prizes.

A Knuckleboom Crane Operator Challenge makes its debut at the World of Concrete regional Crane Operator & Rigger Skills Competition.

In addition, four telescopic boom crane operators will be selected as World of Concrete regional finalists for the Crane Operator & Rigger Skills Championship, to be held later in 2015. CIC began holding regional events hosted by CIC Practical Examiners and their partners in October 2014. CIC Regional Crane Operator & Rigger Skills Competitions continue through June 2015. Grand Prize for the Championship is $10,000.

Operators compete on two cranes at a regional event in late 2014. The course is similar to what operators will face at World of Concrete.

Judges and CIC Practical Examiners from Crane Institute of America and other organizations will oversee both crane courses, which are designed to assess precision, depth perception, and load control. “Tasks will reflect typical activities experienced on real job sites, which is a defining characteristic of CIC certifications,” said Jim Headley, CEO of CIC and President of Crane Institute of America. In addition, operators will be evaluated on proper rigging selection, sponsored by Columbus McKinnon.

“Crane Institute Companies is pleased to have been invited to participate in World of Concrete’s Outdoor Events. With educational sessions, hands-on activities, and hundreds of exhibitors, this show provides something for someone in every level of a construction contractor organization,” said Headley.

Western Star, in partnership with its dealers Hoover Truck & Bus Centers and Modern Group, will supply the cranes for the Crane Operator & Rigger Skills Competition. Serving Eastern Pennsylvania, New Jersey, and Delaware, Modern Group is supplying an Elliott 36127R boom truck mounted on a Western Star chassis for the telescopic boom crane skills competition.

A Hiab XS622 articulating boom crane, also on a Western Star chassis, is sponsored by Hoover Truck & Bus Centers, based in New Jersey. Also supporting the event is HBC Radiomatic, which will provide radio remote controls for the Knuckleboom Crane Operator Challenge.

Both cranes will be set up on SafetyTech outrigger pads provided by DICA Outrigger Pads. “SafetyTech outrigger pads are strong and rigid, provide excellent load distribution, ergonomic safety, and ease of use with any outrigger supported equipment,” said Kevin Koberg, Marketing Director for DICA.

Supported by several professional concrete contractor associations, Crane Institute of America is offering registration discounts to operators who are employed by member companies of Concrete Foundations Association, National Precast Concrete Association, Precast/Prestressed Concrete Institute, and the Tilt-Up Concrete Association. Member companies should contact Eduardo Carcache to receive your discount promo code at ecarcache@craneinstitute.com.

Crane operators are encouraged to pre-register for the competition, as limited spots are available. Registration for the Crane Operator & Rigger Skills Competition is $50. Go to www.cicert.com/news/compete to register. All participants in the Crane Operator & Rigger Skills Competition must also be registered attendees of World of Concrete. To register for the show, visit bit.ly/WOCwithCFA. The Crane Operator & Rigger Skills Competition will take place in the Gold Lot, in front of the North Hall.

CFA Provides Members Discounted Participation

Hanley Wood has worked with the Crane Institute of America to provide an opportunity to members of the Concrete Foundations Association for a discounted registration fee. By using a dedicated registration code for this competition, CFA members will receive a $10 reduction in the registration fee. Contact CFA Headquarters for the CFA co-sponsor discount code. Registration for World of Concrete attendance is also lowest through the CFA by registering online at bit.ly/WOCwithCFA.

About Crane Institute of America

For almost 30 years Crane Institute of America, Sanford, Fla., has offered training for operators, inspectors, safety managers, lift directors, and riggers and signalpersons working with mobile cranes, overhead cranes, tower cranes, aerial lift and forklifts. It is an authorized CIC written and practical exam testing site. For information, visit www.craneinstitute.com.

About Crane Institute Certification

Crane Institute Certification (CIC), Villa Rica, Ga., is an independent certifying organization providing OSHA recognized, NCCA and ANSI accredited certifications for mobile crane operators according to type and capacity, as well as rigger and signalperson certifications. Other programs include certifications for operators of service/mechanics trucks, articulating boom cranes, and digger derricks. CIC serves construction, utility and power generation, underground construction, manufacturing, and heavy industry. Learn more at www.cicert.com.

Hanley Wood Agrees to Sell Exhibitions Business to Informa

Parties to Enter Into Long-Term Partnership Agreement

WASHINGTON, D.C., November 18, 2014 – Hanley Wood, the premier information, media, event, and strategic marketing services company serving the residential, commercial design and construction industries, announced today that it has reached an agreement to sell its Hanley Wood Exhibitions business to Informa PLC, a UK-based publishing and events company that operates in more than 40 countries and is one of the world’s leading knowledge providers. The sale is subject to customary regulatory review and is expected to close by the end of 2014. Upon the closing of the transaction, the Exhibitions business will be rebranded Informa Exhibitions US and will maintain its headquarters in Irving, TX under the continued leadership of Rick McConnell as President, Informa Exhibitions US, Construction and Real Estate.

“Since 2000, Hanley Wood Exhibitions has led the industry as a best-in-class producer of tremendously vital and successful events,” said Peter Goldstone, Hanley Wood’s Chief Executive Officer. “Informa recognized the power and value of the trade show business we’ve built over the years. Informa has an exciting, long-term strategic vision for the Exhibitions business and how it fits within its international operations and its existing portfolio of construction and real estate events. It will be a great home for its customers and employees.”

Mr. Goldstone added, “Part of the reason that Informa was interested in this transaction was the excellence of the management team and employees, and I personally want to thank all the outstanding employees of Hanley Wood Exhibitions for their dedication and hard work for so many years. I have cherished working with them during these past few years, and I offer my heartfelt appreciation and best wishes for the future.”

“We are very excited about the addition of such an outstanding trade show business,” said Stephen A. Carter, Group Chief Executive of Informa. “This is a terrific portfolio of leading construction exhibition brands that will become a key component of our Global Exhibitions Division. In combination with other recent acquisitions, we have significantly strengthened our presence in the U.S., demonstrating our commitment to the sector and the region.”

Hanley Wood and Informa PLC will enter into a long-term partnership agreement under which Hanley Wood will continue to provide editorial and marketing support for Exhibitions events.

“This partnership agreement will allow Hanley Wood Media to maintain its role as the official media and information provider to the various events we have supported for many years,” said Goldstone. “At the same time, our shared customers, business partners and attendees will benefit from the continued collaboration between the two companies.”

Hanley Wood

One Thomas Circle, N.W., Suite 600

Washington, DC 20005

Main 202.452.0800

Fax 202.785.1974

www.hanleywood.com

* * * * *

About Hanley Wood

Hanley Wood is the premier information, media, event, and strategic marketing services company serving the residential, commercial design and construction industries. Utilizing the largest editorial- and analytics-driven construction market database, the company produces powerful market data and insights; award-winning publications, newsletters and websites; marquee trade shows and executive events; and strategic marketing solutions. To learn more, visit www.hanleywood.com.

About Informa PLC

Informa operates at the heart of the Knowledge and Information economy. It is one of the world’s leading business intelligence, knowledge and events businesses with more than 6,000 employees in over 100 offices across 25 countries. To learn more, visit www.Informa.com.