U.S. Department of Labor’s OSHA Extends Compliance Date for Electronically Submitting Injury, Illness Reports to December 15, 2017

WASHINGTON, DC – To allow affected employers additional time to become familiar with a new electronic reporting system launched on August 1, 2017, the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) has extended the date by which employers must electronically report injury and illness data through the Injury Tracking Application (ITA) to December 15, 2017.

WASHINGTON, DC – To allow affected employers additional time to become familiar with a new electronic reporting system launched on August 1, 2017, the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) has extended the date by which employers must electronically report injury and illness data through the Injury Tracking Application (ITA) to December 15, 2017.

OSHA’s final rule to Improve Tracking of Workplace Injuries and Illnesses sets December 15, 2017, as the date for compliance (a two-week extension from the December 1, 2017, compliance date in the proposed rule). The rule requires certain employers to electronically submit injury and illness information they are already required to keep under existing OSHA regulations.

Unless an employer is under federal jurisdiction, the following OSHA-approved State Plans have not yet adopted the requirement to submit injury and illness reports electronically: California, Maryland, Minnesota, South Carolina, Utah, Washington, and Wyoming. Establishments in these states are not currently required to submit their summary data through the ITA. Similarly, state and local government establishments in Illinois, Maine, New Jersey, and New York are not currently required to submit their data through the ITA.

OSHA is currently reviewing the other provisions of its final rule to Improve Tracking of Workplace Injuries and Illnesses, and intends to publish a notice of proposed rulemaking to reconsider, revise, or remove portions of that rule in 2018.

Under the Occupational Safety and Health Act of 1970, employers are responsible for providing safe and healthful workplaces for their employees. OSHA’s role is to ensure these conditions for America’s working men and women by setting and enforcing standards, and providing training, education and assistance. For more information, visit www.osha.gov.

U.S. Department of Labor news materials are accessible at http://www.dol.gov. The Department’s Reasonable Accommodation Resource Center converts departmental information and documents into alternative formats, which include Braille and large print. For alternative format requests, please contact the Department at (202) 693-7828 (voice) or (800) 877-8339 (federal relay).

Putzmeister To Unveil New 30-Meter Class of Truck-Mounted Concrete Boom Pumps

STURTEVANT, WIS. (Nov. 21, 2018) – Putzmeister America, Inc. (Putzmeister) will introduce its redesigned, optimized line of 30-meter class Truck-Mounted Concrete Boom Pumps in 2018. Each model shares a calm, sturdy pedestal with increased strength and a more robust structure, as well as new options packages for customization compared to the line’s previous iterations.

STURTEVANT, WIS. (Nov. 21, 2018) – Putzmeister America, Inc. (Putzmeister) will introduce its redesigned, optimized line of 30-meter class Truck-Mounted Concrete Boom Pumps in 2018. Each model shares a calm, sturdy pedestal with increased strength and a more robust structure, as well as new options packages for customization compared to the line’s previous iterations.

“Across the board, these are to be among the most durable pieces of equipment in Putzmeister’s history,” said Dave Wright, Truck-Mounted Concrete Pump Manager for Putzmeister. “Not a thing has been overlooked with this 30-meter class. Everything is polished, thought-out and improved — from hydraulic and electric line routings to pedestal and boom designs. We’re building on the hallmarks of the well-received 47Z-Meter, which was introduced at World of Concrete 2017.”

All units in the 30-meter class, which has been in development for three years, share a common pedestal. These units also feature the Ergonic® 2.0 control system and the same 3rd generation exclusive Putzmeister Free Flow Hydraulics that are already standard on many of the company’s boom pumps. However, a point of differentiation exists with the smaller boom sizes, which have a smaller overall outrigger span, which equates to smaller front and rear outriggers as well as a shorter deck.

Every model in the 30-meter class features improvements based on customer feedback. For instance, the outrigger cylinder hydraulic line — which was previously welded — is now a bolted connection for easy maintenance and repair. Slewable rear deck steps increase access to the deck, and bottom steps fold up for travel to avoid damage. A decreased side profile, which reduces the overall height and makes for easier loading of pipe and hose on the side decks, is also standard. Additional features include a cleanout ball catcher added at the hopper outlet, and a standard auto lube to “A” hinge.”

“Our extensive research, development and field testing was very effective,” Wright said. “There were multiple stages of technical assumptions, proven analysis, validation, destructive testing and field testing. The engineering and R&D testing was slow and deliberate to ensure every aspect of each new model was evaluated. We took the time to get everything perfect.”

Model-specific advancements were also made as necessary to improve performance. The 31Z-Meter features the same boom with a first section that was modified and lengthened to account for its offset head. Its pedestal is also new and more robust than its previous version.

Reinforced pedestals are also featured on the 36Z-Meter and on the recently introduced, well-liked 5-section 38-Z Meter boom. The 36Z-Meter also includes a new boom design, which is a shortened version of the new 39Z boom.

The brand-new 39Z-Meter features an innovative boom design, robust pedestal design, and can be configured to meet virtually any pumping application. Though impressive durability was a priority, it has not come at the expense of excessive added weight — it remains lighter than Putzmeister’s current, comparable 38Z-Meter.

“The 39Z is our jack-of-all-trades,” Wright said. “With the BSA 39Z.13 HPD Multi, it is an all-in-one unit with detachable placing boom, BSA pump strength and boom pump-level output combined. It’s a super-customizable unit that’s not been previously available in the market.

Three models in Putzmeister’s 30-meter class maintain weights that are comparable to current models — even with the more robust pedestal. The common pedestal, which was design-tested to an extended lifespan, has been strengthened to better withstand torsion from the pump. It also includes thicker rear outrigger legs than previous versions; the front outrigger legs have longer section overlap for increased strength.

About Putzmeister America, Inc.

Specializing in concrete and material placing equipment for the construction industry, Putzmeister America, Inc. is the North American division of one of the world’s most recognized and respected heavy equipment manufacturers, Putzmeister Concrete Pumps GmbH. Putzmeister America, Inc. manufactures a complete line of truck-mounted concrete boom pumps, separate placing booms, truck-mounted telescopic belt conveyors and trailer-mounted concrete pumps, as well as mortar, grout, shotcrete, plaster and fireproofing pumps and mixers, industrial pumps, tunneling machinery and pipeline systems. Some of the industry’s best known brands, such as Telebelt®, and Thom-Katt® are part of the Putzmeister America family. The company’s workforce is dedicated to hands-on customer support and advancing the industry in design and technical innovation. Visit www.PutzmeisterAmerica.com for more information on the company, its products and services.

Seven Lessons Learned From Firing 300 People

Over the course of many years, I’ve fired more than 300 employees at our concrete construction company.

The list of reasons for the dismissals is long and varied. I’ve fired people because they’ve caused problems on job sites, refused to take direction from their Foremen, stolen from the company or coworkers, been under the influence of drugs or alcohol, and a number of other offences.

Most of the time, though, I’ve let people go because they just weren’t working hard enough. Even after discussions about working harder and being more productive, they stayed in first gear and never improved. This has been the most common reason for letting someone go.

Along the way, I’ve learned a few lessons that may help you when you find yourself in the same situation.

Lesson #1: Do It in Private

There are very rare exceptions where you have to fire someone immediately and publicly to set an example for the entire organization. In those cases, do it compellingly and be sure everyone knows exactly why the person is being fired. In the other 99% of cases, let the person go in private and without a lot of employees around.

For example, if all of your laborers come into the office in the morning before heading out to the job site, keep the person to be fired at your office until the crews have left. Then fire the person. Let them leave with dignity.

Lesson #2: You Never Know How the Firing Will Go

The people you don’t think will cause a problem will sometimes be the most trouble for you. Those that you are sure will make a huge scene will sometimes go away quietly. You never know. Expect the best outcome, but be prepared for anything.

Lesson #3: They Will Be Surprised

Most employees believe they are working harder than anyone else on the job site. Their dismissal will be a surprise to them. They will insist that you talk with their coworkers to substantiate their value. These coworkers, by the way, will be the same ones that demanded that you get that person off their crew and replace them with a better worker.

Lesson #4: Have Others Present

Lesson #4: Have Others Present

If you think the person you are going to fire will cause a problem at that moment or later on, then have one or more additional people present during the firing. This will give you witnesses if there is a claim made against you. It will also deter the person from acting out at the time of firing.

Lesson #5: Have A Good Labor Attorney on Speed Dial

Find an exceptional attorney that specializes in labor law and establish a good relationship with them. Make sure they are accessible for a quick phone call if you are mulling over a labor issue. If they don’t return your call for two days, you won’t be likely to call them when you have an urgent issue.

Before acting on a difficult decision or situation, talk with this attorney to get their input. While you don’t have to do exactly as they recommend, they will likely point out something you haven’t yet thought of.

I have to mention that we use the attorney David Whitlock – also a contributor to this magazine – and have found his counsel to be invaluable.

Lesson #6: Pay Them a Little More

In many industries, it is common to pay severance pay when a person is fired. I’ve learned that when you fire an employee, it’s best to pay them for a little extra time. For example, fire them at the bottom of the hour, but pay them until the top of the hour. As you are letting them go explain that you’ll pay them for that extra half hour.

This one simple act costs you little, yet makes the firing go much more smoothly. It also allows you to focus on that act of generosity, which softens the blow and makes them more receptive to the firing. Trust me, this works.

Lesson #7: Sometimes, They’ll Thank You

If a person doesn’t work well at your company, it is often because it’s just not a good fit for them. Their ideal job may be in a totally different industry. When you fire them, you put them one step closer to finding their dream job. We once fired a young man who stopped by our office a few months later simply to thank us for firing him and to report that he was currently working at a job that he loved.

As you’ve surely learned from being in the construction industry, whenever you are dealing with people, it’s impossible to predict how they will react. When you do find yourself in a position where you have to fire someone, consider these seven lessons and you’ll make the dismissal a little easier on you and on them.

Doug Herbert

About the Author

Doug Herbert is President of Herbert Construction Co., one of the largest residential concrete contractors in the southeast. Doug is a regular presenter for the CFA and World of Concrete. He is the Founder of ProfitableContractor.com where he shows concrete contractors how to reduce their costs and increase their profits with effective sales and marketing systems. Reach Doug at Doug@ProfitableContractor.com

Code Compliance with Insulated Concrete Form Foundations

Insulated Concrete Forms (ICFs) are increasingly being used as foundations in commercial and residential projects. Part of the reason is that ICFs naturally help comply with increasingly strict energy codes. While many are familiar with ICFs for above-grade walls, their benefits transfer to foundations as well. Energy code compliance, quicker more efficient construction, and safer site conditions are present in ICF construction, whether above or below grade. However, it is the need for improved energy performance in foundations that is really driving the use of ICFs below grade. ICFs offer a stay-in-place, double-insulated, steel-reinforced concrete forming system. It is for these reasons many designers and contractors are choosing ICF walls.

Insulated Concrete Forms are increasingly being used as foundation walls.

Building Codes and Energy Efficiency

Energy codes have been changing rapidly. Designers and builders must keep up with and be compliant with these changes. Changes include stricter requirements for continuous insulation, higher R-Values and tighter building envelopes. These requirements are now changing the landscape of exterior wall assemblies.

Insulated concrete form (ICF) wall systems inherently meet the new building code requirements. Designers, contractors, and owners can comply knowing that the ICF wall has an exterior and interior continuous insulation panel of typically 2-5/8 in. thick expanded polystyrene (EPS) continuous insulation on every project. Combined, the two layers of insulation meet and exceed today’s energy code standards, even in the most stringent climate zones.

A typical straight ICF block segment.

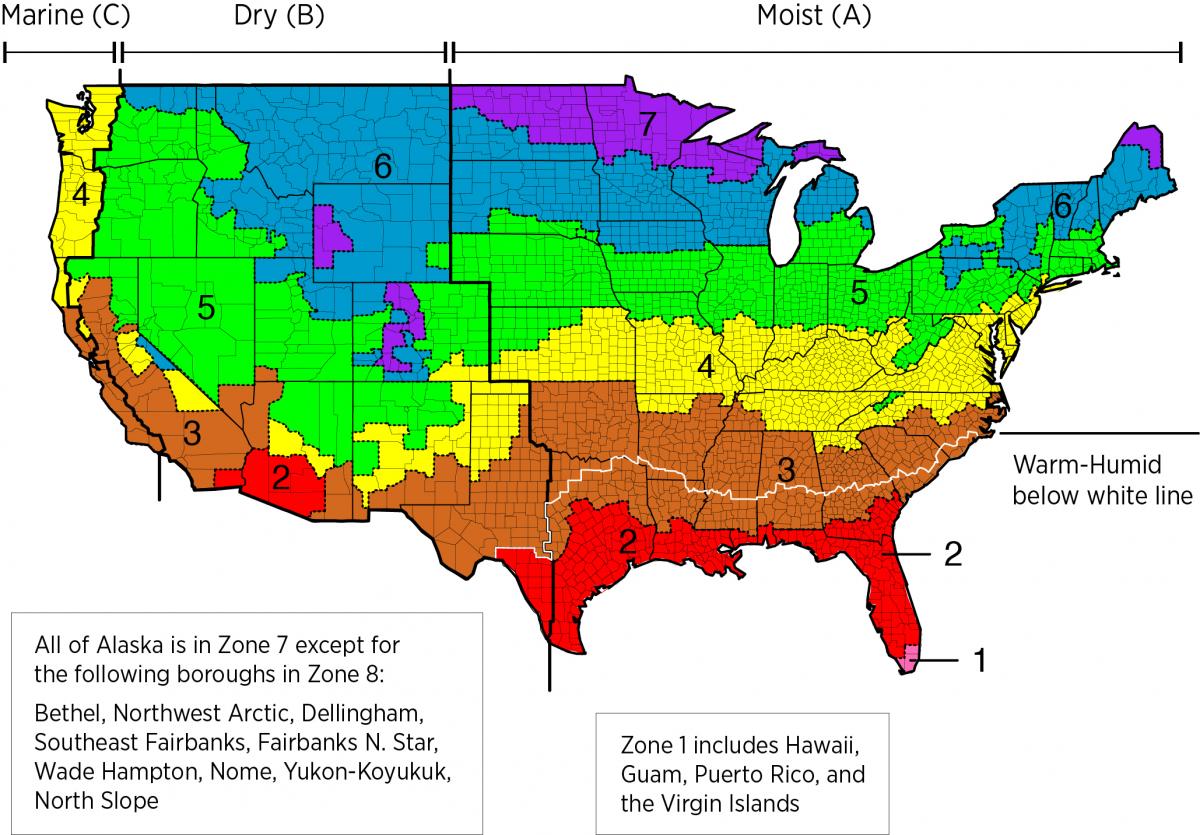

The applicable energy standards referenced by the International Residential Code (IRC) and International Building Code (IBC) include ASHRAE 90.1 and the International Energy Conservation Code (IECC). These documents establish the requirements for continuous insulation and R-Value requirements. Chapter 11 of the 2015 IRC defines the energy efficiency requirements for residential construction. The map in Figure 1 depicts the location of the different climate zones and corresponds to IRC tables providing county-by-county listings of climate zones and R-Value requirements for both above grade and foundation walls. This information is duplicated in the IECC, whereas Chapter 13 of the IBC refers the user directly to the IECC.

2015 IRC Climate Zone Map

The IECC divides the United States into eight climate zones, each with specific requirements for the type, placement and amount of insulating materials – both cavity and continuous – in the wall assembly. Several versions of the IECC are currently in effect across the country (visit iccsafe.org for look-up), making it vital to be aware of which version has been adopted by the state or local jurisdiction in which a project is located.

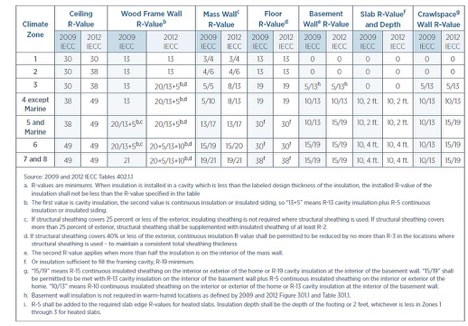

R-Value Requirements from 2009 and 2012 IECC

Each update of ASHRAE Standard 90.1 and IECC adoption has increased the amount of continuous insulation required in commercial buildings (see Figure 2).

The latest ASHRAE Standard 189.1, Standard for the Design of High Performance Green Buildings adds the requirement for an air barrier as well as requiring and increasing the thickness of C.I. in ALL climate zones (1-8).

ICF walls typically provide continuous insulation layers totaling an R-22+ as well as a continuous air barrier found in the solid, monolithic continuous concrete core. This core also qualifies the building envelope component as a mass wall by building codes. Mass walls typically require less R-Value insulation than non-mass or cavity walls. The most stringent climate zone requires an R-19 for a mass wall, which is less than the typical ICF.

Therefore, these new energy code requirements have not affected the ICF wall assembly price or speed of construction in order to meet the new code requirements. Other wall systems, including masonry walls and traditionally formed concrete walls, have had to make a more concerted effort to meet the new energy code requirements. These efforts have significantly affected both the cost and scheduling of these systems.

Prior to the increased energy code standards, these wall system types were not typically as energy efficient as an ICF wall. Even with the new continuous insulation and energy requirements, the traditional systems still do not match the natural ICF energy performance, which in many instances exceed code requirements.

ICF corner block segment

Whereas previous codes only alluded to general air sealing of the building envelope, the 2015 IECC changed to a mandatory requirement for air barrier performance. This includes specific, mandatory provisions for air barriers in climate zones 4-8. The requirements may be met through the use of approved materials, approved assemblies, or whole building air leakage testing (ASTM E779). As more states adopt this code, these provisions will become mandatory for designers of commercial buildings in those jurisdictions.

The energy code requirements of today have forced some building systems to need additional continuous insulation as part of their assembly. Installing these additional layers has added material and labor costs. It has also impacted the construction scheduling and construction time for some systems. There is little doubt that future codes will be even more stringent when pertaining to energy efficiency.

Building Code Requirements

Insulated concrete form building systems have an ASTM standard, ASTM E2634 adopted by both the IRC and the IBC. This standard provides the minimum requirements for certifying any ICF system. In the IRC, insulating concrete forms are provisioned in Sections R404 and R608 and can also be found addressed in the referenced concrete code, ACI 332, which is an optional requirement code for residential concrete design.

Benefitting the Construction Process

Because colder climates translate to higher insulation requirements, concrete and concrete placement into the ICF formwork is protected by the double-insulated, stay-in-place concrete formwork. Concrete work and the ICF walls can continue in colder weather where masonry and traditional concrete wall construction may be shut down or require expensive heating and sheltering to continue in the cold weather.

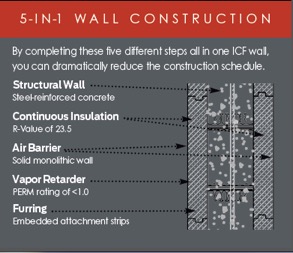

In addition to the newer energy code requirements that are driving more designs towards ICF construction, there are also many advantages that contractors are enjoying. ICF is often referred to as a 5-in-1 construction. This means the ICF wall assembly consists of 1) a structural concrete wall, 2) a double-sided continuous insulation, 3) furring or studs on both sides of the concrete wall for interior and exterior attachment, 4) an air barrier, and 5) a vapor retarder. Any other wall system requires multiple steps to add layers to the assembly in order to achieve the same result. The net result of this 5-in-1 construction is reduced construction costs and schedules, largely due to a reduction in the number of trades involved in the wall construction. Time is saved completing the building shell sooner as other sub-trades such as electricians, plumbers, and drywallers can begin work earlier as well.

ICFs Provide a 5-in-1 Construction Assembly

While larger capital investments, maintenance, handling and storage for reusable formwork is eliminated, contractors also discover that ICF formwork is easy and light to work with, positively impacting the physical health of the workforce and improving job site safety by reducing job site incidents.

While the building codes are driving toward tighter building envelopes and less energy consumption, ultimately, there are many reasons ICFs are increasingly used in residential and commercial construction. When added up, it comes down to meeting codes while saving time and money.

About the Author

About the Author

Kelvin Doerr, P.E. is a registered professional engineer with a Bachelor of Science in Civil Engineering from the University of Nebraska-Lincoln and a MBA degree from University of Nebraska-Omaha. He has 19 years of experience working in the insulating concrete form (ICF) industry with Fox Blocks. He has been involved with several different industry technical committees through the years. Was on the committee to create and write the ASTM E2634 standard for flat wall ICFs. The ACI 332 and ACI 560 technical committees. The EPS-IA technical committee. Has a designed and a patent on a couple of ICF ancillary products.

Planning for the Future Workforce

Understanding how to recruit, train, and motivate a younger generation is helping create successful industry leaders – and social media is helping.

by Tina Grady Barbaccia, AEC Editorial Specialist, Constructive Communication, Inc.

One of the common stories in concrete construction that remains today is that of the son or daughter who began working with his/her dad on construction jobs during the summers. During those teenage years, many will often claim they never anticipated it would become a lucrative career, one that would see them become leaders of their own crews, sometimes not long after becoming full-time employees.

This type of success story remains common for someone in the construction industry in the post-Millennial generation, fondly referred to as the “21 & Under Crews,” and is part of the latest excitement at Lee’s Summit, Mo.-based ABI Corporation. It is significant, especially as the industry faces an aging workforce, a shortage of qualified workers and image issues.

However, by providing good on-the-job training, appealing to what motivates the younger generation, and educating prospective workers about the many opportunities available in the construction industry, finding qualified workers may not be so difficult in the future.

“When I started at ABI, my friends saw me working hard and doing well and they all wanted jobs,” Engel Jr. says. A handful of Engel Jr.’s friends applied at the company and now work as part of his crew with plans to make their job a career.

“When I started at ABI, my friends saw me working hard and doing well and they all wanted jobs,” Engel Jr. says. A handful of Engel Jr.’s friends applied at the company and now work as part of his crew with plans to make their job a career.

One of Engel Jr.’s friends – now on his crew and part of the 21 & Under age group – had been working at a fast food restaurant when he realized that he was able to make the same amount of money working 40 hours a week in construction as working 80 hours a week in fast food. It was then that he decided to pursue a job in the construction industry and make it a career.

Mike Doherty, a crew leader/foreman for ABI Corporation, started his career in the construction industry at a young age when he realized it would pave the way for a profession with great opportunities.

Doherty, now 22 years old, realized after one semester of college that it wasn’t a good fit for him. “College isn’t for everyone,” he says. “There are a lot of people who have a good head on their shoulders and can succeed without a four-year degree. Find something that you are good at or like to do and work really hard. If you do that, have common sense and intelligence, you will get noticed pretty quickly.”

Doherty recognized that he needed a job that allowed him to be physical. He says he also realized that the construction industry would provide a steady income and that skills and talents can sometimes pay almost as much – sometimes even more – than a job that requires a four-year degree. Good, on-the-job training such as Doherty received from experienced industry veteran Brandon Mitchell, who has now moved up to a superintendent position, and other seasoned crew members, sealed the deal on his career choice.

“You need to figure out what works for you,” Doherty says. “Whatever is going to make you go to work every day and make you enjoy your job is more valuable to me than what is going to make someone else happy. Give everything a chance until you find something you are passionate about and makes you want to go to work every day.”

Now, Doherty says his best recruiting tool for showing others what the industry has to offer is himself. His success and love for his job help dispel the mindset sometimes associated with the construction industry – that it is a “last resort option” and just a paycheck.

“I came in at the very bottom of the totem pole as a beginning laborer,” he says. “I worked as hard and learned as much as I could, and within a year and a half, they saw my potential and that I’d be around for a while. You can really make a job in this industry into a lifelong career. Don’t worry about the money. The money will come.”

Balancing multigenerational crews

Balancing multigenerational crews

Being a young foreman has its advantages but it doesn’t come without its obstacles, especially when leading a multigenerational crew. Doherty says the generation above him taught him “everything he knows,” and that “about half of his crew is 10 to 15 years older,” than him.

“They want younger guys in this industry – someone who can be around for a while so they can teach their trade to them,” Doherty says. “They want to train a new generation to come in and take over.”

However, this leadership position at a younger age also comes with paying your dues by starting out as a new laborer and putting your all into the job to really learn how the job is done – that is, done well and correctly.

“The older generation and more experienced members of my crew helped me figure out everything I didn’t master yet and how to get through tougher challenges,” Doherty says. “These people have been around the business for years and years and are valuable. There are times when I am teaching 20-year-olds and times I’m teaching people who have been here for a while. We all learn from each other.”

Although there may be some animosity when a younger crew leader takes over, this is remedied by going on the job and proving to the more experienced crew members that you really paid attention while being trained and that you respect them and what they have taught.

“When you go out and prove to them that you know what you are doing, respect can be earned,” Doherty says. “That respect isn’t just given though. You have to earn it from people who have been doing this job since you were five years old and show that you can work just as long and hard as them and do the job right.”

Showing success on social media

Showing success on social media

With their young leadership, Doherty and others at ABI have dispelled the often pre-conceived notion that the current generation new to the job force and those soon entering it don’t want to work hard – and they and their young crew members are doing so via social media with the “Under 21” Facebook group.

Ironically, they use the social media group as a way – almost a competition – to show just how hard they do work. Many of the “21 & Under” crew members are active on the “Foundation Contractors…the Wall Dogs,” a closed Facebook group with nearly 2,900 members, and use the group as a way to share successes and accomplishments.

Using a social media platform – something this age group identifies with and understands – has been effective in motivating the young crew members and leaders. It is providing a way to show accomplishments and share ideas to learn from each other.

“The crews all work hard then they post it to the Facebook page,” says Jeremy Engel Jr., a 21 & Under lead crew member. “They want to show what they have gotten done. It motivates them to show their work and use it as fuel. It’s kind of like a competition on who can work the hardest or set the biggest wall.”

It makes sense to combine Facebook and work, Engel Jr. points out, because all of the crew is familiar with Facebook and they all need to be at work every day. “Why not combine the two – work and Facebook – and make the best of it?” he says. “It’s a great way to show the accomplishments of everyone going to work and giving it their all.”

Doherty adds that it also provides a good opportunity to see what other companies in the industry in different states and throughout the country are doing on their job sites. “There are so many ideas that get thrown out there,” he says. “We can see what other people are doing.”

Plus, a little healthy competition never hurts. “One of my biggest training tools is competition,” Doherty says. “Whenever we get to show something off and say we were able to get it done in this amount of time, I think it makes the guys feel good.”

Finding and training young talent

Recruiting and retaining young talent in the construction industry has become increasingly important with an aging workforce. This means finding future employees and foreman and ensuring they are taught how to do a job correctly. It also means showing the younger generation that there are many opportunities in the business and identifying future leaders.

How do you recognize potential young talent?

“You look for someone with a light in their eyes and the drive to work,” says Dan Bromley, president/part owner of ABI Corporation and past president of the Concrete Foundations Association (CFA).

He takes note when he finds someone who is smart, has a good personality, gets along well with others, is hardworking and has a willingness to do all different types of training.

Bromley says it is important to communicate with promising members of this younger generation, to let them know if they have been pinpointed as future foremen or equipment operators and tell them the steps necessary to get there. If these future leaders are able to pass a drug screen and do not have any DUI/DWI history on their driver’s licenses, Bromley finds out what their goals are and how they view their future.

“As soon as we see someone younger with talent and the drive and intelligence to succeed, we work on getting them their commercial driver’s license (CDL),” he says. “When we need to replace someone, we want to be able to fill the position with someone we have already trained.”

Bromley points out that almost every person who has moved up in the company or has a supervisor role (with the exception of accounting) has started as a laborer. This is important to help them understand the business from the ground up. “If your driving record is clean and you work hard, you will move up,” he says. “Even if a position is not open, the company is big enough where there are always opportunities.”

Bromley shares the example of one young employee who had passed the written exam for his CDL but just wasn’t able to get down shifting the truck.

“We spent a week with him driving in a quarry to teach him how to do it properly,” he says. “You earn loyal workers when you spend time working with and training them, making sure they know how to do a job properly. It might not always work out, but it’s an investment. You have to try.”

ABI takes the same approach with training new employees and potential foremen time and time again, with management remembering what it was like just starting out and the importance of someone taking the time to teach them.

Many foremen don’t have the patience and don’t put the time in to teach the crews to complete their tasks the right way. At ABI, the focus is on teaching crews to do it right; we preach the importance of doing it correctly, not fast. Speed is a product that comes with experience and time. No expectations are made for new hires to be able to just come out, set forms and pour concrete on day one.

And though the younger generation has to earn the respect of the experienced workers, the team at ABI believes that respecting those learning goes a long way. Accessibility to and visibility of mentors and even, at times, father figures by those being trained is critical. “Give them respect, receive respect back” is a slogan that one perceives when listening to the stories told by these mentors. From respect grows confidence, loyalty and the performance that keeps the younger generation crews around.

It can be difficult to be patient when trying to teach or get a point across that may be second nature to an industry veteran, but it’s a key to success. Some of the main points the ABI crew leaders make are: 1) Don’t yell at them and call them idiots. 2) Give them the respect they deserve. 3) You’ll get more guys to work for you if you treat them nicely than if you are a grumpy “S.O…G” (son of a gun).

Ultimately, the future depends on training the current young workforce and finding prospective industry leaders, and ABI’s training and management approach sets this standard. In fact, supervisors and their teams are often glad to be teaching the trade to a younger generation that they see as motivated and hardworking. Instead of voicing frustration with this new generation of possible labor force, they realize that if this generation doesn’t do it, we won’t have anywhere to live.

What final word of advice do they give? “These kids really are interested in what we are trying to teach them. When people say underage kids don’t want to work, they don’t know our group.”

Recharging Your Leadership

CFA Board of Directors adds four new faces for 2017-2020

By James Baty

Brian Cottom

Jay Middleton

Matt Van Wyk

Scott Renfroe

Like most organizations, the Board of Directors is the governing body for the Concrete Foundations Association (CFA). It consists of leaders volunteering their time, attention and financial resources in response to their pride and passion for this industry. As the CFA fiscal calendar turns each summer, one of the most apparent changes is that of participants on the Board of Directors. This is an exciting time that also comes with appreciation and melancholy.

At present, this Board consists of 20 individuals serving staggered three-year terms. Three seats represent the exclusive membership category of National Associates, manufacturing and supply companies that represent the top echelon of products, equipment and technology that shape the present and future of cast-in-place concrete. The remaining seventeen seats are at-large positions for contractor, professional, consultant and builder members of the Association.

Transitioning off of the Board this past July was a group of individuals who represent much of the time-honored history, current passion and on-going fabric defining the essence of this Association. Tom Brown, formerly of TJ Construction in Ely, Iowa served from 2008 until this year, participating through some of the most challenging times this Association has ever experienced. At the same time, these years evidenced the greatest expansion of benefits and programs ever achieved for Association members and the industry at large. Josh Esker of J.B. Esker & Sons in Teutopolis, Illinois served one term from 2014 to 2017 as a second-generation Board member, and joining him in that stretch of service was Dan Buser of Dandee Concrete Construction in Kearney, Nebraska. In addition to the service of these three contractor members, Lindsay Castles, president of GMX, Inc., completed his term on the Board as one of the most recently expanded positions in service for the National Associates. It is with great accolades and appreciation that the membership thanks the service of these four leaders.

Transition brings hope and promise for the future, for moving forward. The Board has added four individuals from diverse backgrounds and geographies, further evidence of the reach of this Association and its value to the industry. Joining the Board are Brian Cottom of Woodco, Inc., in Terre Haute, Indiana; Scott Renfroe of Foundation Builders, Inc., in Greeley, Colorado; Matt Van Wyk of Van Wyks, Inc., in Waldo, Wisconsin; and, filling the National Associate seat, Jay Middleton of Helix. Who are these individuals and how have they come to be part of the CFA Board? We turn to each of them in this article to find out a bit of their background for you and some insights to their leadership over the next three years.

Transition brings hope and promise for the future, for moving forward. The Board has added four individuals from diverse backgrounds and geographies, further evidence of the reach of this Association and its value to the industry. Joining the Board are Brian Cottom of Woodco, Inc., in Terre Haute, Indiana; Scott Renfroe of Foundation Builders, Inc., in Greeley, Colorado; Matt Van Wyk of Van Wyks, Inc., in Waldo, Wisconsin; and, filling the National Associate seat, Jay Middleton of Helix. Who are these individuals and how have they come to be part of the CFA Board? We turn to each of them in this article to find out a bit of their background for you and some insights to their leadership over the next three years.

Q: What is your earliest memory of the concrete industry? (This question was asked as a way of connecting readers with the new members’ pasts to give a foundation for their future leadership. Renfroe and Van Wyk are second-generation CFA members, both having fathers who served on the Board.)

Scott: My dad, Jack, started our foundation company in 1972. I can remember getting up early on Saturday mornings when I was about 7 or 8 and driving around with my dad to check on jobs. When we would stop at a job site I can remember climbing over the panels or climbing on the form trucks. I also remember getting to finish with a mag float if we were pouring a footing.

Matt: A tough question, as I’ve been around this my entire life. I would say it was when I was 9 years old and my father started building our new shop. I had been off of school and I got to participate pouring and floating the edges. It was the first time I can say I did something with concrete other than writing my initials in fresh concrete.

Brian: My grandfather was a union carpenter, so I was around construction from an early age. But when I was seven or eight years old, one day a crew of guys showed up at our house. Next thing I remember, several big trucks arrived and this “mud” started coming out the back. The following day I had an awesome basketball court. That was cool. I’ve been in love with concrete ever since!

Jay: I watched as an additional section of basement was added to my childhood home.

Q: Considering the background you each have and the length of time you’ve been around the business of concrete, what would you say is your biggest challenge faced in today’s construction market as a business owner/operator/manager?

Brian: It has to be the workforce: finding and keeping dependable, drug free, qualified people.

Brian: It has to be the workforce: finding and keeping dependable, drug free, qualified people.

Matt: Definitely the demands of the workforce. That is, finding quality employees, keeping those employees and making each of their needs to be the priority.

Scott: Every day has its challenges. Skilled labor shortages are always a challenge, especially trying to meet the needs and timelines of each builder we work for in a very busy market.

Jay: My perspective is from dealing with new technologies. There is a conflict between conservative evaluation and revenue generation. This currently works to stagnate the migration of great ideas and proven concepts to successful implementation and integration.

Q: Considering that running a business has such a challenge, what piece of wisdom do you recall from your mother and/or father that you put into practice in business today?

Scott: My father would always say, “You must always take care of your employees and subcontractors. If they do not make money, they can’t help you make money.” The best compliment we can receive is for a friend or employee to want us to work for them. If they trust us with that job we have done our job correctly.

Q: Matt, that sounds like it fits in with your previous response on honoring your workers. I wanted to ask you to expand that thought about making your employees’ needs a priority.

Matt: Listen, I’ve learned that in order to keep good employees you have to show you care about them, hear them and try to honor them. The bigger you are, the harder this is, but all the more important so no one feels lost or devalued. As for advice, my father, whom I took over this business from would always tell me, “Do not keep your eggs in one basket.” His meaning was to be diverse. As markets change, you’ll need to change. Customers’ expectations are all different and therefore it is important to never have only one!

Jay: Never give up.

Brian: I have to go with my grandma. She always said, “You can’t judge a book by its cover.” This taught me from a young age that a person’s skin color, clothes or whether they had a roof over their head or not didn’t determine who they were.

Q: It seems there is definite influence of the past on the ways you run your businesses and a great wealth of advice you’ve received and are passing on. If you had to convey what most interests you in serving as a CFA board member, what would that be?

Brian: Giving back to an organization that tries to better my industry is simply my duty. And I’ve found that you will always learn something along the way.

Brian: Giving back to an organization that tries to better my industry is simply my duty. And I’ve found that you will always learn something along the way.

Matt: Being a servant to my peers. As I grew up, I got to know some of the most successful men in this industry and have been around them when they were leaders of their companies and as CFA board members. Listening to other members, learning what is important to them and finding out what they want from the CFA makes me better, my company better. This inspires me to bring my own knowledge to the table.

Scott: I am interested in giving back to CFA and the members because of how much they have been there for our company when an issue or question has occurred. I am also interested in continuing the research into the captive insurance market for concrete contractors. I still think there is a better future for insuring our attention to quality and safety.

Q: It is exciting to learn of your passion in this way. When you think of CFA, what is the first word that comes to your mind and why?

Matt: Therapy . . . that is, group therapy for the contractor. We all have new problems we haven’t faced yet, and someone in this group already has and is willing to give you the information about what they have done about it in the past.

Jay: Basement: My impression is the that building basement foundations is the core business of the majority of members.

Scott: Expertise. When you attend a meeting or talk with a member you will learn something.

Brian: I have to agree, and my word would be “helpful.” I haven’t met anyone from officers to suppliers to contractors that weren’t interested in sharing useful information. It makes me a better contractor every time I look to the CFA.

Q: There are certainly a lot more contractors who will read this and are not members than there are reading this who are. As a challenge to someone whose company has not yet tried CFA membership or who has not yet been able to experience some of what you have described, what one piece of advice would you offer?

Jay: I attended my first summer event in Santa Fe. Other than the beautiful scenery of the location I remember the discussions related to ACI332 the most. What I found is that CFA is the least expensive access to the best industry-specific continuing education and business consultation available. It is commonplace to hear members say they learned something at an association meeting that saved them tens of thousands of dollars in the following months.

Scott: About fifteen years ago we attended a meeting in Breckenridge, Colorado. I remember the high-quality speakers and the friendly, contractors from around the country who openly discussed current issues we all face. Every owner cares about their company and wants to strengthen their company in one way or another. The CFA and its members will provide the best technical information and access to successful concrete companies from around the country that can help with information about the best business practices for any situation, and you will be given the opportunity to share what makes your company great with others.

Matt: I agree with Scott. In fact, my first meeting I remember was likely the same one he attended. My first time sitting in round tables was at Breckinridge CO; I was 16-ish, give or take. I sat listening to Greg Peacock talk about wall failures. Although Greg was from Atlanta and I did not expect to have the same relevance as where I am in Wisconsin, it was spot-on identical. We all had the same progressive quality issues and were perusing better training methods to the main issues. I’d recommend asking yourself, if you find your business struggling to be productive, have quality, or be profitable, how are you going to know if you are achieving your goals to their fullest potential? These peer relationships are easy and effective. I have found that comparing myself to others within the CFA is one of my most effective business tools.

Brian: The first CFA event I can recall was in Nashville back in the 90s. What I remember learning the most was that everyone else had the same problems. Gave me some hope, I guess. Just starting in business and dealing with all these issues back then, I thought I was doing everything wrong. Find a way to be part of this conversation. You won’t regret it.

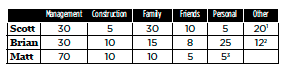

Q: Our last question for the contractor members was related to time management. Realizing they have all volunteered to give a portion of the next three years to this Association and indirectly to the industry at large, they have challenged you to see the value in personally getting involved and perhaps even getting to an event. Most will either try to dismiss their affordability or ask, how do they do it? Where does this time come from? We ask them to divide their time each week into the buckets based on percentages so you can perhaps relate more easily in line with your own commitments.

1 Scott manages several other companies, which are development opportunities, and has served in the Colorado State Senate

2 Brian commits a strong percentage of his time to his church

3 Matt offers that if you don’t find an outlet personally, you’ll go insane.

We look forward to learning more from these new board members, along with Jay Middleton, as the progress of managing this Association and this industry continues. To learn more about any of these gentlemen or to connect with a CFA board member directly, please contact CFA Staff or visit the Association website, www.cfaconcretepros.org, and select from the “About” menu.

SCHWING AMERICA ACQUIRES ASSETS OF LOOP BELT INDUSTRIES

ST. PAUL, MINN. (September 29, 2017) – Schwing America, worldwide designer, manufacturer and distributor of premium concrete production and handling equipment, announced the closing of transaction for the purchase of all the assets of Loop Belt Industries, makers of high-quality truck mounted telescopic conveyors.

“We are thrilled to acquire the assets of Loop Belt Industries and incorporate them into the Schwing family,” said Bill Murray, CEO of Schwing America. “This asset purchase adds diversification to our existing portfolio and will provide our customers with enhanced high-performance concrete and aggregate conveying options.”

The acquisition, which was finalized on September 21, includes intellectual property, patents, patent applications, copyrights and trademarks, among other assets. The Loop Belt products include 33-Meter and 40-Meter truck mounted telescopic conveyors, a tractor trailer mounted 40-Meter conveyer, and a tower mounted conveyor for stationary applications.

“The Loop Belt product line complements Schwing’s concrete machinery portfolio in a strategic way enabling our customers to grow with Schwing,” said Tom O’Malley, Senior Vice President of Sales & Marketing. “The advanced design features, including an all tubular steel boom, 20-inch wide belts and flexible outriggers, offer users a reliable unit that can convey several types of materials including concrete, aggregates and sand.”

Along with the asset purchase, Schwing has hired Loop Belt Industries President, Joseph Gallione as a Senior Product Engineer & Operations Support Manager. Joe will continue to lead the Loop Belt product line in its current operating model and the transition of Loop Belt production from Glen Ellyn to Schwing’s manufacturing facility in White Bear Lake, Minnesota.

For more information or high-resolution images, contact laudan@linnihanfoy.com

About Schwing America

Schwing America is part of the Schwing Group, headquartered in Herne, Germany with plants as well as sales and service centers in several countries. Located in St. Paul, Minn., Schwing America manufactures industry leading concrete pumps, truck mixers, reclaimers, long reach hydro excavators and genuine parts for distribution in North and Latin America. http://info.schwing.com/e/83972/2017-09-29/8chrnk/278990254

Profoundly Impacted by Convention

This issue of the magazine introduces the newest CFA Board members. One of the common threads between them is easily found in the profound impact that Convention, meeting and networking with peers has had on them. This is not unique by any stretch of the imagination to a member of the Board. Talk with any one from a company that has been around for a few years, particularly the owner or manager that has had the chance to actually attend, and you will hear resounding stories of personal and professional achievement and evolution that has come from such an environment. It is, in the end, what established the CFA and what has maintained it through some of the most dire and difficult economic cycles since 1974.

“We thank Schwing, Putzmeister, Thermomass, Building Point, Nox-Crete, BIK Hydraulics, Irving Equipment, GMX, Concrete Forms Services and Concrete Contractor Magazine as well as AutoCar, Fox Blocks, Helix Steel and the Tennessee Concrete Association for 2017 sponsorship.”

attended CFA Convention after learning about the event.

This year, however, we had the chance to experience a new kind of difference making. One might suggest that CFA has seemingly grown up as our event began to attract attention from a broader spectrum than the cast-in-place residential concrete contractor. A college student from New York, who is working through her degree in architecture had her mom contact us to see if it would be possible to attend. Desiring a more hands-on or realistic understanding of materials, this young professional-to-be found out about our convention, asked her parents if it would be possible to take a vacation to Tennessee so she could be present, and then started the process of contacting us to register. While we extended the opportunity for the whole family to attend, our anticipation for the impact we might have was small. It was enough of an honor to be recognized as a place to impact the next generation of designers.

The week after the event, we received messages from both Leslie and her mom. “I just wanted to thank you for allowing myself and family to attend the conference at no cost. I’m so grateful that I was able to come and learn about concrete, and meet others that held an appreciation for the material. The conference definitely widened my views of concrete and its possibilities and now, more than ever, I consider concrete more of a versatile and invaluable material.”

When was the last time you legitimately considered your industry, the material you make a living from, as invaluable. A portion of the good will and the investment in others was passed along to this family and in turn, the future appreciation for the livelihood you enjoy was ensured just a bit more. Well done, attendees to Concrete Foundations Convention 2017. You made a difference in the life of yet another tomorrow through your hospitality.

CFA Executive Director, James Baty | jbaty@cfaconcretepros.org

Success Only Comes After Work!

The only place success comes before work is in the dictionary. After many years in business, I can attest to that being a “Concrete Fact.”

Becoming a CFA member will never take the hard work out of success, but membership sure can lighten the load and, hopefully, help avoid the pitfalls of our industry through sharing the experiences of its members.

“If you are willing to do more than you are paid to do, eventually you will be paid to do more than you do.”

(anonymous)

I had the pleasure of contacting some Board Members to inform them that their terms were about to expire and to ask them if they would consider another term. One particular Board Member answered, “Absolutely.” He commented, “I thought I really knew a lot about the concrete business before I got on the Board. The knowledge gained in participation on the Board has been invaluable to my business.”

As a member of this Association, you are welcome to attend Board meetings. Please understand there is no member any more important than you. By just attending Board meetings, your participation in the Association is not only important to your business, but your input and sharing of your experiences can influence many others in their paths to success.

Making changes in your business operations/ventures without consulting others with similar experiences can make the difference between succeeding and failing. I can speak with experience on this one. Some years ago, I had a conversation with a fellow member with regard to a venture that I gave up on but that he was very successful at. He told me that my failure could be easily explained: “You didn’t throw enough money at it.” Looking back, he was absolutely right. I did not consult with others who had experience in that particular venture, and when I struggled, I just gave up.

A fellow member called me just this past week with a concern over a piece of equipment purchased at this summer’s meeting in Nashville. My comment to him was that he purchased his equipment from a very reputable CFA Associate Member who I knew supplied excellent support with the purchase, and that he should not be afraid to make good use of that.

I would like to thank everyone who attended and supported this summer’s meeting in Nashville. I hope all who attended enjoyed themselves and was able to take valuable knowledge back home with them. There seemed to be considerable enthusiasm generated during the three days there.

My wife and I are looking forward to next summer’s meeting in Utah and are encouraging other family members to attend with us so we can all enjoy a mini vacation.

Dennis Purinton, Purinton Builders Inc., CFA President 2016-18, purintonbuilders@yahoo.com

Acceptable Tolerances for Residential Footings

As published in Concrete Contractor Magazine, August/September 2017. This column pertains to the nature of minimum requirements or specifications for the size of concrete footings in relation to the foundation walls they support.

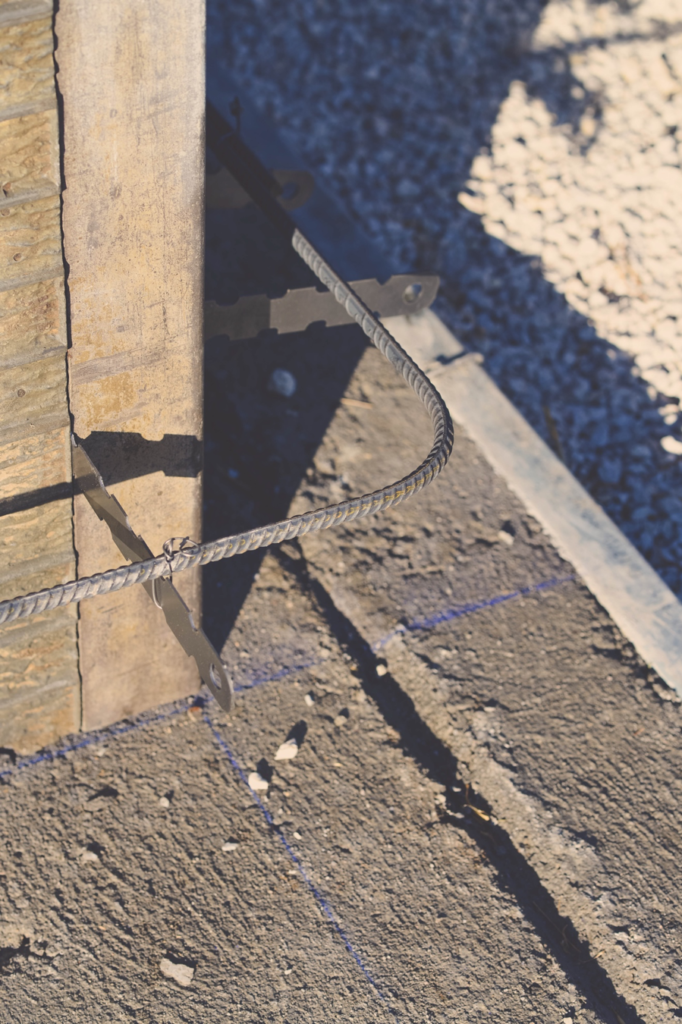

Chalk lines on the footing designate the inner formwork wall line. The width of the footing minus the wall thickness should leave enough footing along the outside to support the wall forms.

Question:

I have a foundation that was poured and I am not impressed. The footings were poured and when they set the wall forms, there was visible deviation in how much the footings extended past the walls. Why don’t they check their measurements for size?

Answer:

This is not an uncommon issue in the marketplace and contractors need to understand the basis for the concern as well as the information that can assist the commenter in moving forward with comfort or finding an appropriate solution. Aside from the obvious conflict in the relationship, this inquiry is one of proper, minimum and acceptable footing projection dimensions. In order to clarify the concern for the owner and help them move forward in this project, a look at the current building codes is important.

The International Residential Code (IRC)1, as this column has discussed in the past, is the reference most utilized by designers, contractors and code authorities throughout the U.S. Depending on the state or jurisdiction of adoption, variances in the effective IRC edition and possible modifications applied to that base code exist. In short, the prescription for footing design and construction in the IRC moves quickly from a basic and simple concept to a potentially complex or confusing adaptation of construction technology and system support.

The IRC opens the discussion of footings with a general statement of requirement (R403.1), applied to the structural support of residential structures that could be slab-on-ground; built on a crawl space; or incorporating a full lower living level or basement. Here it states:

All exterior walls shall be supported on continuous solid or fully grouted masonry or concrete footings, crushed stone footings, wood foundations, or other approved structural systems which shall be of sufficient design to accommodate all loads according to Section R301 and to transmit the resulting loads to the soil within the limitations as determined from the character of the soil. Footings shall be supported on undisturbed natural soils or engineered fill. Concrete footing shall be designed and constructed in accordance with the provisions of Section R403 or in accordance with ACI 3322.

A forming crew worker checks the square on a foundation set. Variations in the actual line of the set wall forms on the footing are possible when final measurement checks are made.

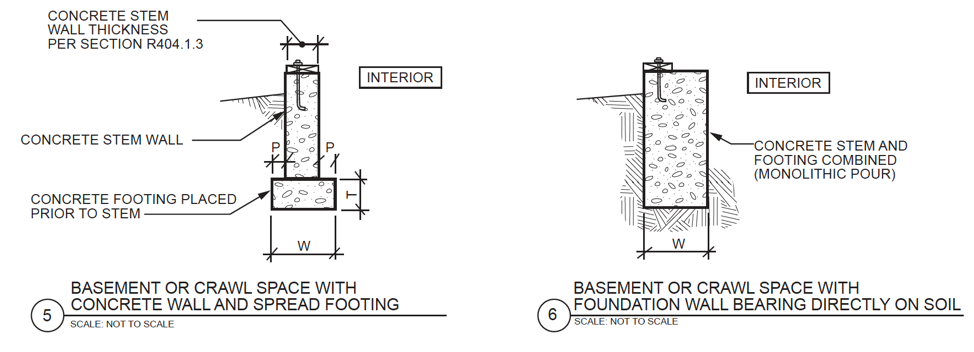

It is important to understand that a formed concrete footing is not a general requirement in order to adequately distribute the exterior wall loads of a residential structure conforming to the IRC; one- and two-family dwellings of no more than three stories above grade. While this is the section on footings, at the very basic level, exterior walls for a residential dwelling must be supported effectively to the soil condition in a manner sufficient for the classification of that soil. In the language of the IRC, crushed stone is just as acceptable for bearing as a concrete footing. In fact, later in the IRC the user will find prescriptive requirements for precast and wood foundation walls most often bearing on gravel footings. In effect, a concrete foundation wall can be supported on a gravel footing with these same confinement specifications as well as the concrete wall bearing directly on the soil, provided the contact with that soil is of sufficient width for the soil bearing capacity.

It is a fact of code development that minimum provisions follow proven construction practice. Therefore, the cast-in-place concrete or grouted masonry foundation walls, which have historically desired a concrete footing for the consistent and clean surface it provides, become prescriptively related to concrete footings while precast and wood foundations are related to gravel footings. It is important to note, although, that such gravel footings are restricted to seismic zones A, B and C only.

Next, the IRC prescribes the geometry for a footing in section R403.1.1.

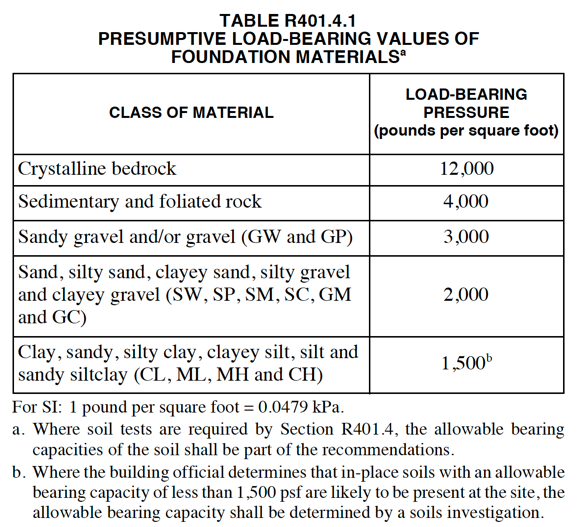

The footing width shall be based on the load-bearing value of the soil in accordance with Table R401.4.1. Footing projections, P, shall be not less than 2 inches (51 mm) and shall not exceed the thickness of the footing.

Table 401.4.1 as printed in the 2015 International Residential Code. www.iccsafe.org

The footing width, no matter the construction type, is governed then by the soil bearing capacity. Soil types range from very poor capacity or low load-bearing pressure as found in sandy, silty and weak clays (1,500 psf) to very high capacity as found in crystalline bedrock (12,000 psf). The weight of the residence transferred through the structure ultimately accumulates to a total load at the contact point with the soil. When compared to the prescribed or tested bearing capacity of the soil, the footing width is then increased until sufficient width equalizes the load to the capacity. Tables in the IRC provide a quick determination of the minimum width and thickness of the concrete footing but at no point in any table is the concrete footing less than 12 in. wide nor less than 6 in. thickness.

As shown in the 2015 International Residential Code (as well as previous versions) foundation walls are shown on footings and bearing directly on soil, Figure R403.1(1).]

As noted in detail 6 above, the bearing width of a foundation wall may be sufficient to support the loads on the given soil. However, most concrete foundation walls are actually formed on concrete footings. The IRC prescribes an absolute minimum footing width of 12 in., which is a result of concrete and masonry walls (those most often using concrete footings) having a common minimum width of 8 in. plus the minimum projection of 2 in. on each side, thus the 12-in. total. The owner in this inquiry comments on the deviation of the location of the wall to the footing, thus challenging the consistency or equivalence of the minimum projection (P). As a concrete footing is excavated or forms constructed and ultimately concrete placed, it is possible for the exterior or interior line of the footing to become altered. As long as the minimum width is maintained, as prescribed by the code or shown on the prints, the performance of the footing for load transfer will be effective. ACI 332 (noted earlier from IRC section 403.1), states in its prescription:

7.2.1 Wall footings

7.2.1.1 Wall footing width shall be at least the greater of the applicable dimensions specified in Tables 7.2.1.1a through 7.2.1.1h or the supported wall thickness plus 4 in.

This code does provide further commentary on the minimum projection dimensions as a practical way of supporting the forming system, an answer to why the 4 in. of extra thickness is established:

R7.2.1.1 Footing widths need to project a minimum of 2 in. on each side of the wall to support the forming system. The footing width projection is measured from the face of the concrete wall to the edge of the footing.

ACI 332 brings further relevance to this discussion by referencing ACI 1173 for construction tolerances. General and application specific tolerances for foundation systems are found in this code-referenced document, where section 3.2—Deviation from Location, states:

Where the foundation dimension is less than 8 ft, the greater of +/-2% of specified dimension or 1/2 in.

ACI 117 then provides section 3.5—Deviation from cross-sectional dimension of foundation, in which the effective width of the footing or foundation is given a tolerance. Those are:

Formed Foundations

Horizontal deviation………+2 in., –1/2 in.

Unformed Foundations cast against soil, horizontal deviation from plan dimension. Excavation shall be measured before concrete placement. Tolerance shall apply at all locations.

Where dimension is 2 ft or less ………………………+3 in., –1/2 in.

Where dimension is more than 2 ft ………………….+6 in.–1/2 in.

It is therefore acceptable for an IRC-prescribed minimum concrete footing of 12 in. (w) x 6 in. (t) with projections of 2 in. to be allowed tolerance to a width range of 11.5 to 15 in. with a minimum projection of 1.5 in. The IRC also states that the projection cannot be greater than the footing thickness, in which case a plan tolerance here would permit the maximum project ion of 6 in. to be as great as 9 in. without being reinforced (seismic zones A, B and C only).

Construction and forming accuracy are important aspects of a solid quality assurance program for professional concrete companies, no less so for those whose markets are primarily residential or agricultural. Acceptability in code minimum requirements and applied tolerances should not be an excuse for a lack of commitment to such quality assurance, however, they should also not be used as leverage by a home owner, builder or code authority for the purposes of claiming incompetence.

Want to know more? CFA Executive Director, James Baty, FACI, participates in many discussions of construction and code application for Association members, designers and code authorities. Contact him at 866-232-9255 or by email at jbaty@cfaconcretepros.org. The Concrete Foundations Association mission is to support the cast-in-place contractor as the voice and recognized authority for the residential concrete industry. ACI documents can be obtained by contacting the CFA or by visiting the American Concrete Institute (www.concrete.org) and ordering from their bookstore.

References:

- 2015 International Residential Code® For One- and Two-Family Dwellings published by the International Code Council, Inc., 4051 West Flossmoor Road, Country Club Hills, IL 60478-5795 | Phone 1-888-422-7233 | www.iccsafe.org

- Residential Code Requirements for Structural Concrete (ACI 332-14) and Commentary published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org

- Specification for Tolerances for Concrete Construction and Materials (ACI 117-10) and Commentary published by the American Concrete Institute, 38800 Country Club Drive, Farmington Hills, MI 48331 | Phone: 248-848-3700 | www.concrete.org