2022 PROJECTS OF THE YEAR

Español | Translation Provided by the CFA

SETTING A CULTURE OF PRIDE

The North American landscape continues to hide the most creative and challenging concrete installations each year. Now in its 23rd year, this program continues with its vision to give voice and expression to the great work completed every day throughout the markets that serve, support, and establish the art and science of residential construction. Companies across membership have expressed the value of having projects be submitted to an awards program. It honors the crews involved and instills pride in them for their achievement. When selected as one of the unique projects in a given class, these companies recognize the importance of memorializing their accomplishments and sharing their appreciation with the customers and partners who trusted them to deliver on the challenge.

In early 2022, Association members were once again invited to consider projects from their portfolios they felt represent exceptional craftsmanship and construction quality, unusual achievement, project complexity, and integration of advancing technology to set new standards. These criteria are not often thought about in an industry where the finished product is quickly covered up as it is built upon. Yet, companies on the leading edge understand the value of looking closely to recognize the quality solutions produced in the field for the work requested by the customer, specified by designers, and commissioned by builders.

What does it take to submit a project? The major consideration involves planning, as it takes both the ability to describe requirements and results as well as photographic or video documentation of the performance. With these in hand, any company can take this opportunity to advance their company culture and contribute to industry advancement.

So, without further delay, the Concrete Foundations Association publishes the top achievements in concrete projects for 2022—the CFA Projects of the Year, which were awarded during #CFACON22, held in Boston, Massachusetts, this past July. Some familiar and some new recipients once again demonstrate the diverse landscape of project types, sizes, complexity, and experiences.

_________________________________________________________________________________

2K-5K SINGLE-FAMILY RESIDENTIAL FOUNDATION AWARD

PERMA-STRUCTO, INC.

Elizabeth Lake | Twin Lakes, Wisconsin

Tales of the Tape:

- Linear Feet of Wall: 614

- Square Feet: 4,370 (house) – 7,650 total (garage & porches)

- Yards of Concrete: 230

- Steel Reinforcement: 11,000 lbs.

- Wall Heights: 3′-4″ to 13’-0” (twelve heights)

- Wall Thickness: 10”, 12″ and 14”

This project had numerous steps in the footings due to soil conditions and its lakeside location along with taller than average wall heights. While mostly 10′ 0″ & 11′ 4″ walls, they reached as high as 13′-0″. Using modular aluminum forms, we were able to achieve this variety by stacking and using combinations of 5-ft , 4-ft, 2-ft, 6-ft, 8-ft and 9-ft forms. Given the prior experience on more complex jobs, we were able to participate in this project based on our reputation and deliver it with our attention to detail.

Among the complicated details, there was a dual-level back porch with one level for a hot tub and one level for seating. The wall detailing combined a stepping brick ledge along with a 16-in. deep floor joist interior ledge to facilitate a on-grade entrance for accessibility. The brick ledge stepped at 8-in., 1′-8″, 2′-8″, 3′-8″, 4′-8″, and 5′-8″). Finally, common to such large custom foundation structures, there were multiple, oversized window openings with treated wood bucks cast-in-place.

A phased approach to this project allowed our crews to work simultaneously on other projects with critical schedules. With the efficiency of our operations, all house footings were completed in two days and the walls in six days followed by the garage section with a day each for footings and walls, and finally the porch levels.

_________________________________________________________________________________

UNIQUE/SPECIAL PROJECTS: POOL FOUNDATION

CHAPIN CONCRETE CONTRACTORS INC.

River Bluff Pool Foundation | Chapin, South Carolina

Tales of the Tape:

- Linear Feet of Wall: 425

- Square Feet: 2,345

- Yards of Concrete: 325

- Steel Reinforcement: 40,000 lbs.

- Wall Heights: 1’-0” to 16’-0”

- Wall Thickness: 8” to 20”

- Excavation Mass: 580 cubic yards

- Backfill: 780 tons of #57 stone

This project posed significant challenges not only from the complexity of the foundation work but also from the limited access and the extreme slopes we encountered. This project was constructed on a one-to-one slope. We managed to install a tremendous amount of foundation wall in a very small footprint. We met all the criteria for making a high-quality structure safely anchored into the slope—with zero incidents and virtually no rework or punch-list items to address at the end of the project.

We are extremely proud of all our efforts and the teamwork between our company, other

contractors, and the design professionals involved in this project. The project was so complex that an immense amount of the details had to be coordinated as we built the foundation. We spent hundreds of hours collaborating with everyone involved in the project. This was a once-in-a-career opportunity for our firm, and we are very pleased with our finished work. The success of this project is a testament to the hard work and dedication of our team.

_________________________________________________________________________________

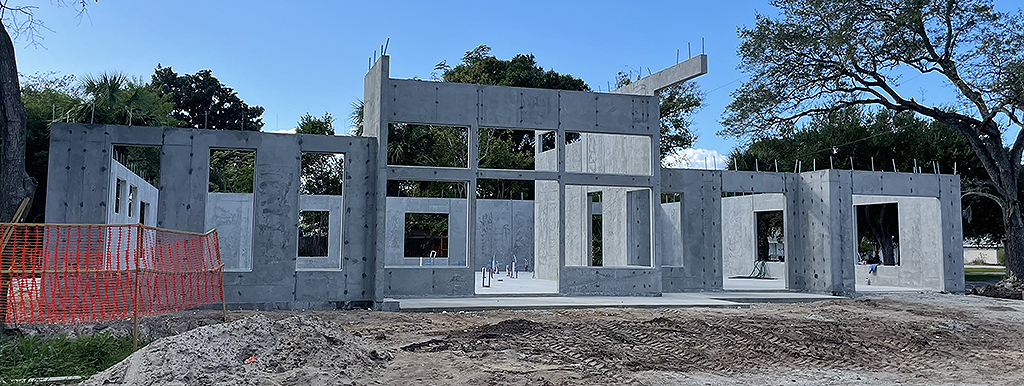

ABOVE-GRADE CONCRETE HOME AWARD

TCB WALLS INC.

Nuvision Custom Homes | Melbourne, Florida

Tales of the Tape:

- Linear Feet of Wall: 301

- Square Feet: 4,217

- Yards of Concrete: 56

- Steel Reinforcement: 4,950 lbs. (bar) 7,560lbs. (Helix TSMR)

- Wall Heights: 10’-0”, 15-0” and 16’-9”

- Wall Thickness: 6” and 8”

This project had a very busy front elevation that seemed to catch everyone’s eye once forms were removed. Many windows were incorporated in the design, resulting in some very thin beams along with a cantilevered beam for the front porch. The design resulted in a “floating roof” with no columns, which gives the finished home a very unique appearance.

While certainly not the largest project we completed during the year, it has a noticeable look, and it nicely features some of the options and character that can be incorporated into an above-grade cast-in-place concrete structure.

_________________________________________________________________________________

UNDER 2K SINGLE-FAMILY RESIDENTIAL FOUNDATION AWARD

O’RISKY EXCAVATING

DHL Cabin | Evansville, Indiana

Tales of the Tape:

- Linear Feet of Wall: 300

- Square Feet: 1,920

- Yards of Concrete: 375

- Steel Reinforcement: 17,500 lbs.

- Wall Heights: 14’-0”

- Wall Thickness: 10”

- Steel Beams: 10,000 lbs.

- Excavation Mass: 10,000+ cubic yards

- Backfill: 5,000 lbs. of stone

This project, though small, had many challenges throughout. The difficult, rough terrain created multiple challenges, including a steep elevation change required to access the site from the county road. This made it necessary for us to produce a temporary concrete road with a rough, “boat ramp” finish to provide enough traction for construction equipment access.

The height of walls and the location were designed to maximize the view of the lake. The steep grade required multiple footing steps in the garage specifically. There was additional steel structural design to support hollow-core precast panels and hot-tub structure steel frame.

Our work gained the respect of local contractors and businesses who have worked and continue to work on this project, and this respect has been reciprocated.

_________________________________________________________________________________

MULTI-FAMILY/TOWNHOME AWARD

TCB WALLS INC.

Elbow Creek Townhomes | Melbourne, Florida

Tales of the Tape:

- Linear Feet of Wall: 3,120

- Yards of Concrete: 1,032

- Steel Reinforcement: 74,000 lbs. (bar)

- 11,127 lbs. (Helix TSMR)

- Wall Heights: 9’-0” and 20-0”

- Wall Thickness: 6” and 8”

This project is a great example of all that you can do with poured walls. We went from pouring a 9-foot-tall retaining wall to pouring 20-foot-tall townhome walls above it using all the same men and equipment. We were able to give this customer a much stronger structural frame than they could have with any other product, and we ended up with a very satisfied owner and general contractor, which is always our goal.

Access to this site was very limited with a river all along one side. The retaining wall was a priority for building up the rest of the property and supporting two of the seven-unit townhomes. They required 7-foot-wide footings with double-mat steel grids of #5 and #6 along and 48-inch dowels at 12-inch o.c.

_________________________________________________________________________________

UNIQUE/SPECIAL PROJECTS: RETROFIT/RENOVATION

TALPEY CONSTRUCTION

Gengras Cottage | Old Saybrook, Connecticut

Tales of the Tape:

- Linear Feet of Wall: 400

- Square Feet: 3,000

- Yards of Concrete: 120

- Steel Reinforcement: 4,000 lbs.

- Wall Heights: 3’-10”, 5’-6”, and 8’-10”

- Wall Thickness: 8” and 10”

This project consisted of making a new foundation under a historic home that would also receive an addition. Footings were located off the existing house once it was jacked up. The new wing was added to the left side, and a big wraparound front porch and garage stepped up from the main house. Additionally, we had footings for column pads and a fireplace that could only be located in the field to match existing condition.

Working underneath a house is always tough. The crib piles are always closer than you’d like, the pours take extra planning because they take longer, and you are locked into whatever dimensions you pull off the existing house. This house also had a center fireplace that needed a foundation up underneath it—high enough for us to be able to make up the difference with a structural slab, low enough for the house lifter to be able to lower the structure without interference.

_________________________________________________________________________________

5K-15K SINGLE-FAMILY RESIDENTIAL FOUNDATION AWARD

WEBER CONCRETE CONSTRUCTION

Hussey Lane | Zionsville, Indiana

Tales of the Tape:

- Linear Feet of Wall: 2,672

- Square Feet: 8,569

- Yards of Concrete: 400

- Steel Reinforcement: 31,980 lbs.

- Wall Heights: 2’-0” to 13’-0” (six total)

- Wall Thickness: 8” to 22” (six total)

- Footing Sizes: 22” by 12” and 48” by 12”

Only a few homes are of estate caliber, and this was one of them. All big houses use large footings, unusual wall proportions, and special specifications for concrete. This was no different from those in other parts of the country, but very unique for our market. The beauty of this house, this estate, set on this lot with all the special features and finishes makes this one of our finest constructions.

The complexity of the project necessitated total organization and focus to ensure each measurement was exact. Our crews double- and triple-checked throughout the project and worked with the client’s engineer and architect throughout construction. This close attention began at the start of the project, where we had three people involved in estimating and detailing, checking each other’s work.

_________________________________________________________________________________

OVERALL GRAND PROJECT: OVER-15K SINGLE-FAMILY RESIDENTIAL FOUNDATION AWARD

SCW FOOTINGS & FOUNDATIONS

Sorensen Residence | Salt Lake City, Utah

Tales of the Tape:

- Linear Feet of Wall: 1,274

- Square Feet: 19,943

- Yards of Concrete: 768

- Steel Reinforcement: 33,066 lbs.

- Wall Heights: 4’-0” to 30’-0” (House)

- 3’-0” to 15’-0” (Garage)

- Wall Thickness: 8”, 10”, and 12”

The massive size of this project meant that we needed to pour the footings and foundations in several sections to accommodate the reach of the pump as well as our available forms to build. The layout spans 275 feet across and consists of 1,144 linear feet of foundation wall. There was a total of 82 in-wall rebar cages/columns to receive post-installed embeds. There was 175 linear feet of shelved foundation to accept a precast floor system above.

The job included 25 separate footing steps, totaling 57 feet in vertical grade changes.

Continuous footing sizes ranged from 24 to 48 inches wide and 12 inches thick with most pad footing sizes ranging from 48 to 156 square inches and 12 to 25 inches thick. One pad footing was 29 feet by 10 feet 6 inches, and although originally designed to be 20 inches thick, site conditions required this to be constructed to 36 inches thick.