Evaluating the Performance of Portland Limestone Cement (Type 1L) and the Mitigating Effects of Liquid Floor Hardeners/Densifiers

By Lee Nabb – Nox-Crete Flooring Division Manager

Abstract:

Portland Limestone Cement (PLC) or Type 1L cement, a blended cement containing limestone, has gained significant market share due to its reduced environmental impact compared to traditional Type 1 Portland Cement. However, recent field experience has highlighted potential challenges when using Type 1L cement such as increased porosity, reduced early strength, and higher abrasion susceptibility compared to traditional Type 1 Portland Cement. This study investigates the performance of Type 1L Portland Cement compared to traditional Type 1 Portland Cement with a specific focus on abrasion resistance. Additionally, the effectiveness of Nox-Crete’s liquid floor hardener/densifiers in mitigating these challenges is explored.

Introduction:

The construction industry is continuously seeking sustainable solutions to minimize environmental impact. Type 1L (T1L) cement, a blended cement incorporating limestone, has emerged as a promising alternative to traditional Type 1 (T1) cement. Industry experts estimate that cement production accounts for approximately 8% of worldwide CO2 (greenhouse gas) emissions; the shift to T1L cement is driven by the desire to lower the carbon footprint associated with cement production.

Despite its environmental benefits, recent field observations suggest potential challenges associated with the use of lower early compressive strengths, and higher porosity, as compared to floors placed with traditional T1 cement. These characteristics can lead to concerns regarding the durability and performance of concrete structures, particularly in applications such as manufacturing facilities and warehouse/distribution centers where abrasion resistance is critical.

Evaluation of Abrasion Resistance:

Evaluation of Abrasion Resistance:

This study aimed to compare the abrasion resistance of concrete test specimens cast using either T1 or T1L cement and assess the potential benefits of Nox-Crete’s liquid floor hardener/densifiers in mitigating any observed abrasion resistance deficiencies. Tabor abrasion testing (per ASTM D4060) was conducted to evaluate the degradation patterns of both cement types over time.

Results:

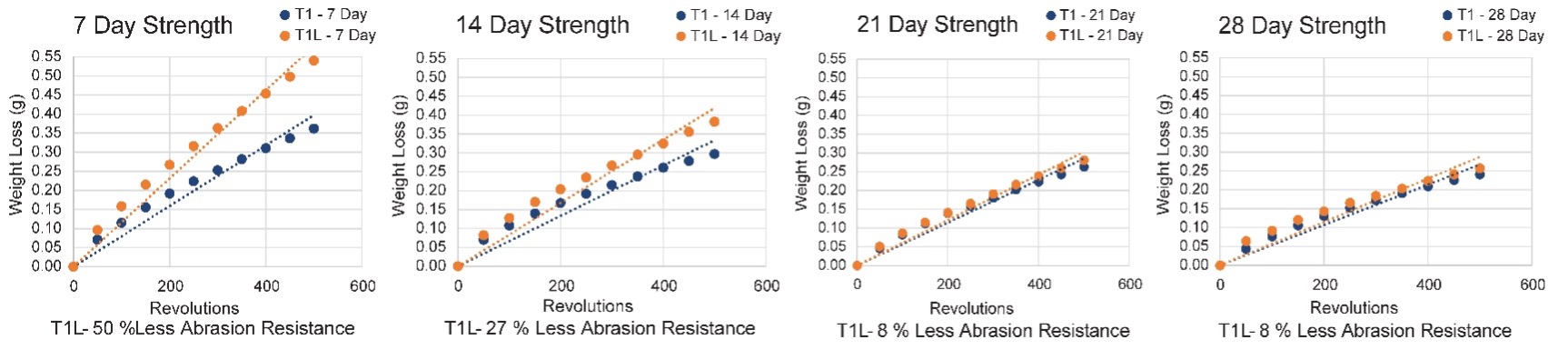

The findings revealed that untreated control specimens using T1 cement exhibited greater early (7-14 days) abrasion resistance compared to specimens cast with T1L cement. At these early stages, T1 specimens displayed approximately 50% and 27% greater abrasion resistance at 7 and 14 days, respectively, compared to specimens containing T1L cement. While the abrasion resistance became more comparable at later stages, T1 specimens still maintained a slight edge at 28 days, with 8% greater abrasion resistance at 500 revolutions compared to the T1L specimens.

Impact of Liquid Floor Hardener/Densifiers:

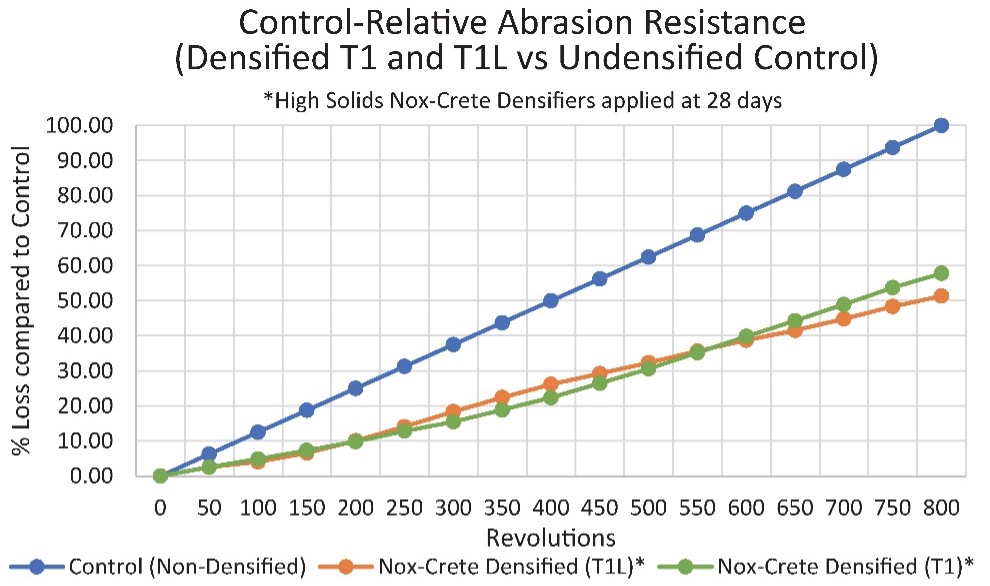

The study also investigated the effectiveness of Nox-Crete’s liquid floor hardener/densifiers in improving the abrasion resistance of T1L-containing concrete. The results indicated that applying a less reactive (lower solids) Nox-Crete densifier at the time of concrete placement, followed by a second application approximately 28 days later, yielded significant abrasion improvement compared to the untreated control. The aforementioned approach substantially improved the early abrasion resistance of T1L concrete, precisely during the period when the concrete exhibits its weakest performance. Thus, in instances where interim slab protection during the construction process is important, applying a coat of liquid floor hardener/densifier early on will afford valuable protection. It was also noted, as confirmed by previous testing, that a single coat application of a more reactive (higher solids) Nox-Crete densifier after a full 28-day cure resulted in the overall best abrasion resistance for both T1 and T1L cement-containing mixes.

Conclusion:

Conclusion:

This study confirms the potential challenges of concrete containing T1L cement as it relates to early abrasion resistance. However, the findings also demonstrate the effectiveness of Nox-Crete’s liquid floor hardener/densifiers in mitigating this challenge. Applying densifiers at strategic points during the construction process can significantly enhance the early abrasion resistance of T1L cement-containing concrete, ensuring optimal performance without compromising environmental benefits.

Future Research:

Further research is recommended to explore the long-term performance of T1L cement-containing concrete treated with a liquid floor hardener/densifier across various environmental conditions and loading scenarios. Additionally, investigations into the potential synergy between densifiers and other supplementary cementitious materials (SCMs) used in conjunction with T1L cement could provide valuable insights for optimizing concrete performance.

Risk Mitigation:

• Verify type of cement to be used on your project

• Communicate with all parties involved

• Review architectural specifications

• If possible, obtain mix design and send to your chemical supplier

• Use trusted sources to stay updated on ongoing changes/developments

• Always attempt a mock-up