Science Fair 2020: Final Report

By: Calvin Menke, 7th grade

Abstract

The question being asked is “Does freezing concrete affect the long term strength?” The purpose of this experiment is to determine the long term strength of concrete after being frozen. The experiment will test concretes breaking points after being frozen.

This researcher hypothesized freezing concrete will affect the long term strength. Freezing the concrete will affect the process of it curing.

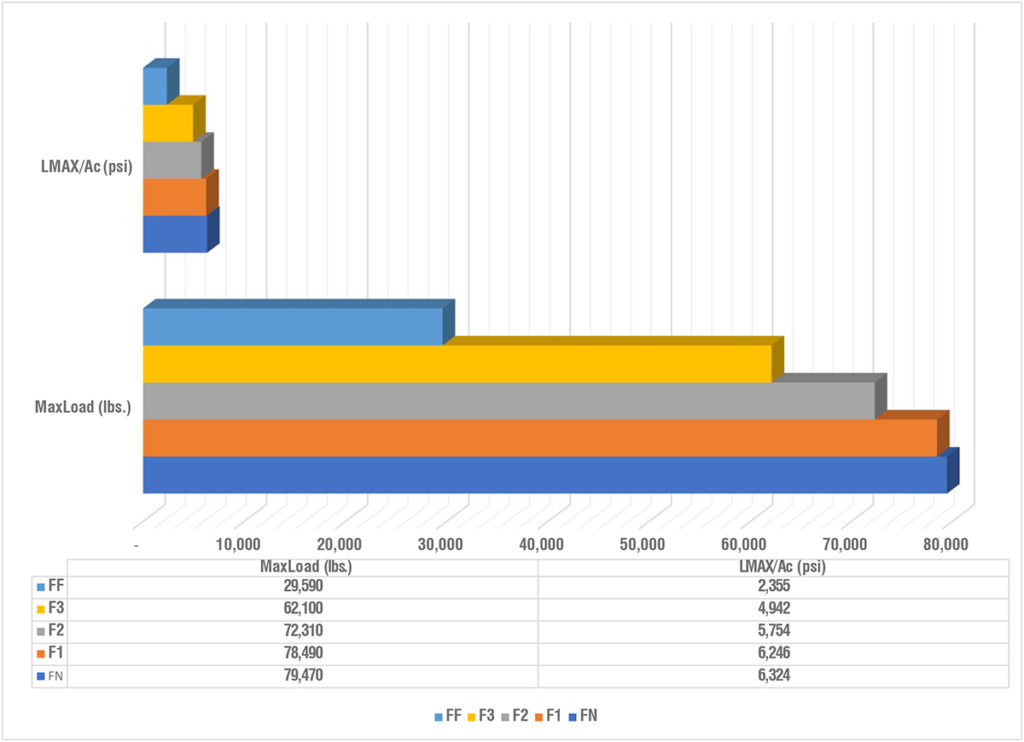

There were 4 tests on the cylinders, the concrete not frozen was the strongest. The second strongest concrete cylinder was the one frozen for one week, then the cylinder frozen for two weeks was the third strongest. The third cylinder frozen was the fourth strongest cylinder, and the one frozen the whole time was the weakest.

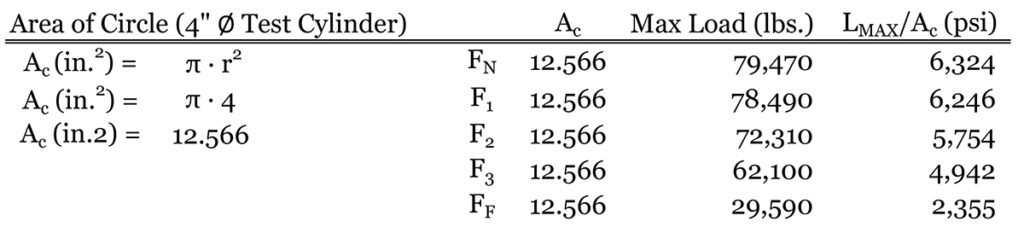

After experimentation it was verified that the results show the concrete not frozen was the strongest and it took 79,470 lbs. (6,324 psi.) to break it. The concrete cylinder that was frozen for one week broke at 78,490 lbs (6,246 psi.). The cylinder froze for two weeks and had a PSI of 5,754 and took 72,310 pounds to break. The third cylinder broke after 62,100 lb (4,942 psi.). The one frozen the whole time had a PSI of 2,355 and took 29,590 pounds to break.

It is concluded that the hypothesis was partially supported. The hydration process stopped because the water was frozen so that’s why the ones frozen for longer didn’t have as much strength as the ones not frozen as long.

Introduction

The question being asked is “Does freezing concrete affect the long term strength?” The purpose of this experiment is to determine the long term strength of concrete after being frozen. Concrete is being used every day; it is driven, walked, and biked on all the time. It is key to see if it is safe to be used every day after being frozen so it doesn’t crack when someone is on it. The experiment will test concrete breaking points after being frozen by placing weight on it and measuring its breaking point.

Research and Background (excerpts)

Why is the strength of concrete measured? One reason why strength of concrete is measured is for some jobs where concrete is being poured, the concrete will have to reach a certain strength. If you don’t meet the strength requirement and the structure breaks, cracks too soon, or injures someone, you then become responsible for their injury.

The process called hydration is from water being added to the cement. The water forms a paste that then binds the aggregate together. The reason concrete gets hard is because the water molecules are forming a chemical bond with the cement. If the water is not pure it will mess up the process of it curing and even weaken it. The last most important thing is 10 to 15 percent cement, 60 to 75 percent aggregate and 15 to 20 percent water. If your mixture isn’t at those percentages, concrete will be weakened and dangerous to be used because it could lead to cracking and all sorts of problems.

How long does it take for concrete to set and cure? Well, it takes approximately 24-28 hours for concrete to set. After or around 7 days concrete has roughly gained about 3 quarters of its compressive strength. You should try to not drive on the concrete until the 28th thru the 30th day. Which is when the concrete is cured on the 28th or 30th day.

Hypothesis

Freezing concrete will affect the long term strength. Because freezing the concrete will affect the process of it curing. If it doesn’t cure properly then it will chip and or crack.

Experiment

Concrete was poured in test cylinders. The cylinders have a diameter of 10.16 (cm.) and a height of 20.32 (cm.). The test cylinders were filled to the top with concrete. After being fully filled they were rodded to get the most accurate test after being broken. Next the concrete cured outside for one day. After they cured for one day the samples were placed at 0˚ C (32˚ F) in the freezer. One cylinder was left out of the freezer. One of the samples were taken out of the freezer on the 7th day. The second sample was taken out of the freezer on the 14th day. Then after 21 days being frozen the cylinder was taken out of the freezer. Then on the 28th day (4th week) the final concrete cylinder was taken out of the freezer. Immediately after being taken out the samples were tested and saw the strength they gained after being frozen.

The results show that my hypothesis was almost completely correct. The results show that the concrete not frozen was the strongest and it took 79,470 total pounds (6,324 psi.) to break it. The second strongest concrete cylinder was the one frozen for one week. This cylinder broke after 78,490 pounds (6,246 psi.) were applied. Then the cylinder frozen for two weeks and had a psi (pounds/square inch) of 5,754 and took 72,310 total pounds to break. The third cylinder which was the third strongest cylinder broke after 62,100 pounds were applied (4,942 psi.). Finally, the one frozen the whole time was the weakest. This had a PSI of 2,355 and took a total of 29,590 pounds to break. My hypothesis stated that freezing concrete will affect the long term strength.

Because freezing the concrete will affect the process of it curing. The long term strength didn’t get affected by freezing the concrete. I know this because the cylinder that was frozen for a week and got the rest of the time to cure and gained almost up to the same amount of strength as the cylinder not frozen at all. Even the cylinder frozen for two weeks had a comparable strength to the non-frozen cylinder.

The reason this happened was because freezing the concrete froze the water in the mixture and it stopped the hydration process. The hydration process is when the water mixes with the cement and has a chemical reaction that makes concrete cure or harden. This can’t happen when the water is frozen. So that’s why the ones frozen for longer didn’t have as much strength as the ones not frozen as long. So the cylinders frozen longer didn’t have as much time to regain strength and become as hard as they could.

One thing I could have done to improve the experiment was rodded the concrete better into the cylinders. It’s easier to break when you don’t rod correctly. This was a slight variable that could have been improved.

About the Author:

Calvin Menke is the son of Matt and Michelle Menke of Menke Brothers Construction Company in Fort Jennings, Ohio. Calvin is in the 7th grade, attending Fort Jennings High School where his emphasis or subject interest is Math and his primary hobbies/interests include sports and helping his grandpa.

When asked, Calvin says he can see himself working for his dad’s company while finishing up his high school career and getting ready for college. The main thing that interests him in the concrete industry is how the chemical reaction (hydration process) can still happen after being frozen. This is the reason he chose this project for the science fair.