Trick of the Trade: The Step-Down Flow-Stop

This ‘Trick of the Trade’ is shared by Mary Wilson of Michel Concrete Inc. in Springfield, IL. Mary offers this solution in response to the challenge by CFA President, Dennis Purinton. Mary’s company is rewarded with 50 points to her member account to be redeemed for an upcoming registration, event or purchase. The tip comes from investigating a solution to a problem identified on their project pours after attending World of Concrete several years ago and working with manufacturers for a solution.

The Problem:

At walkout wall step-ups, when we pour monolithic lower walls, directly adjacent to or in-line with taller walls, hydrostatic pressure has a tendency to force concrete to squeeze over the lower form. This causes the upper wall concrete to sag in the formwork. The more the concrete in the upper wall is worked, the more the concrete escapes over the lower wall form. Our typical application for this is a 3-foot lower wall and a 12-foot full height wall in our market.

The Solution:

Years ago, we started using expanded metal formwork, like that used in one-sided wall construction, to create a shut-off where the short and tall wall meet. Initially we had to cut the large sheets to fit inside our forms, but now we are able to special order the expanded metal in 8-inch by 8-foot tall pieces. We now simply cut the 8-foot piece, with a gas-powered saw, to the height of our lower wall, and wire the expanded metal to the form ties. Extra (we call them dummy ties) are added for more support. We also use shears to cut small holes in the expanded metal, so rebar can run continuous through the shut-off, maintaining reinforcement continuity between the two wall sections. Since the expanded metal is placed below grade, there has been no reason to use waterstop, in this application.

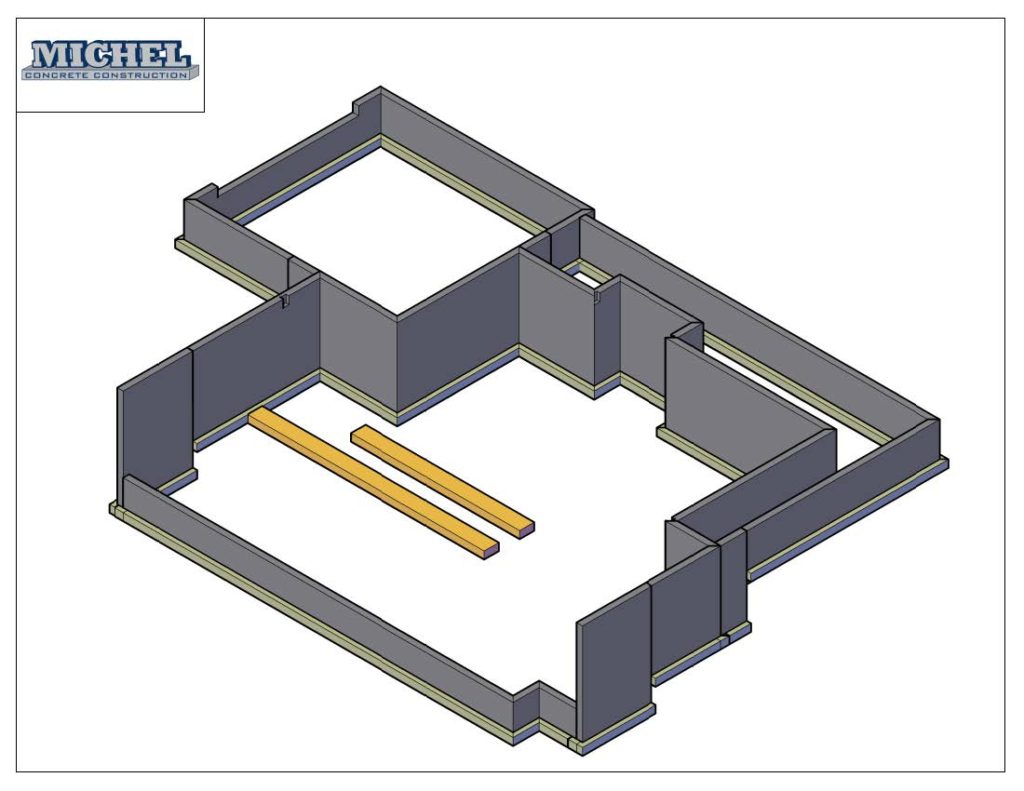

Michel Concrete provides these images to describe the typical location of their step-down condition and the actions that set up the need for the solution. Above shows a 3-d model typically used in their project communications shows the customer what concrete features they are quoting and how they will go about it. Lower right the crew is working at the elevation of the upper wall according to their Fall Protection Plan and trying to control the mounting pressure on the step down to the lower wall. Lower left is the view from the stepdown wall back to the taller wall where flow-stop material holds back the fluid pressure while allowing reinforcement continuity to exist.